Abstract

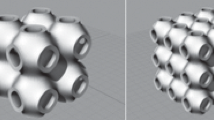

In this paper, the physical and mechanical properties of products with the geometry of a triply periodic minimal energy surfaces (TPMES) are studied by computer simulation. The calculations are performed by the FEN method (hyperelastic viscoplastic fracture with a finite deformation) for typical samples of polyamide-12 material obtained by selective laser sintering (SLS). As a result of the study using the Comsol Multiphysics program, the distribution of mechanical stresses and the appearance of deformed products at various values of the applied mechanical stress, as well as the deformation curves, were obtained. The convergence of the calculations on the mesh size of the model under study is shown. The simulation results are in close agreement with the experimental data. As a result of the study, excellent physical and mechanical characteristics of the samples with the proposed geometry are found.

Similar content being viewed by others

REFERENCES

Bieri-Gross, B. and Nesper, R., Topological modeling of reconstructive phase transitions through periodic surfaces: Tin dioxide I–A calcium chloride to palladium fluoride type transition, Z. Anorg. Allgem. Chem., 2015, vol. 641, pp. 1503–1509.

Makogon A.I., Shevchenko V.Ya., and Sychov M.M., Modeling of reaction-diffusion processes of synthesis of materials with regular (periodic) microstructure, Open Ceram., 2021, in press.

Bieri-Gross, B. and Nesper, R., Topological modeling of reconstructive phase periodic hyperbolic surfaces: The β-quartz to keatite type transition, Zeitschr. Kristallogr., 2011, vol. 226, pp. 670–677.

Shevchenko, V.Ya., Topological forms of future of structural chemistry of new substances and materials, Tr. Kol’sk. Nauch. Tsentra RAN, 2018, vol. 9, no. 2-1, pp. 109–114.

Zürn, A. and Shnering, H.G., Topological analysis of mesoporous solids and their ordered pore structures by periodic nodal surfaces, Z. Anorg. Allgem. Chem., 2008, vol. 634, pp. 2761–2764.

Leoni, S. and Nesper, R., Elucidation of simple pathways for reconstructive phase transitions using periodic equi-surfaces (PES) descriptors. II. The strontium disilicide transition, Solid State Sci., 2003, vol. 5, pp. 95–107.

Nesper, R. and Leoni, S., On tilings and patterns on hyperbolic surfaces and their relation to structural chemistry, ChemPhysChem, 2001, vol. 2, pp. 413–422.

Shevchenko, V.Ya., Koval’chuk, M.V., Oryshchenko, A.S., and Perevislov, S.N., New chemical technologies based on reactive-diffusion turing processes, Dokl. Akad. Nauk, Khim. Nauki Mater., 2021, vol. 496, no. 1, pp. 25–29.

Shevchenko, V.Ya., What is a chemical substance and how it is formed?, Struct. Chem., 2012, vol. 23, no. 4, pp. 1089–1101.

Von Shnering, H.G. and Nesper, R., How nature adapts chemical structures to curved surfaces, Angew. Chem., Int. Ed., 1987, vol. 26, no. 11, pp. 1059–1200.

Andersson, S., Hyde, S.T., Larsson, K., and Lidin, S., Minimal surfaces and structures: From inorganic and metal crystals to cell membranes and biopolymers, Chem. Rev., 1988, vol. 88, no. 1, pp. 221–242.

Andersson, S., Hyde, S.T., and von Schnering, H.G., The intrinsic curvature of solids, Zeitschr. Kristallogr., 1984, vol. 168, nos. 1–4, pp. 1–17.

von Shnering, H.G. and Nesper, R., Nodal surfaces of Fourier series: Fundamental invariants of structured matter, Zeitschr. Phys., B, 1991, vol. 83, pp. 407–412.

Mackay, A.L., Crystallographic surfaces, Proc. R. Soc. London, Ser. A, 1993, vol. 442, no. 1914, pp. 47–59.

Schwarz, H.A., Gesammelte mathematische Abhandlungen, Berlin: Springer, 1933, pp. 1843–1921.

Han, L. and Che, S., An overview of materials with triply periodic minimal surfaces and related geometry: From biological structures to self-assembled systems, Adv. Mater., 2018, vol. 30, no. 17, pp. 0935–9648.

Thomsen, P., Malmström, J., Emanuelsson, L., René, M., and Snis, A., Electron beam-melted, free-form-fabricated titanium alloy implants: Material surface characterization and early bone response in rabbits, J. Biomed. Mater. Res. B, 2009, vol. 90, no. 1, pp. 35–44.

Tancogne-Dejean, T., Spierings, A.B., and Mohr, D., Additively-manufactured metallic micro-lattice materials for high specific energy absorption under static and dynamic loading, Acta Mater., 2016, vol. 116, pp. 14–28.

Leitlmeier, D., Degischer, H.P., and Flankl, H.J., Development of a foaming process for particulate reinforced aluminum melts, Adv. Eng. Mater., 2002, vol. 4, no. 10, pp. 735–740.

Wang, Z., Jiao, X., Feng, P., Wang, X., Liu, Z., and Akhtar, F., Highly porous open cellular TiAl-based intermetallics fabricated by thermal explosion with space holder process, Intermetallics, 2016, vol. 68, pp. 95–100.

Korner, C. and Singer, R.F., Processing of metal foams-challenges and opportunities, Adv. Eng. Mater., 2000, vol. 2, no. 4, pp. 159–165.

Ducheyne, P. and Martens, M., Orderly oriented wire meshes as porous coatings on orthopaedic implants I: Morphology, Clin. Mater., 1986, vol. 1, no. 1, pp. 59–67.

Tancogne-Dejean, T., Spierings, A.B., and Mohr, D., Additively-manufactured metallic micro-lattice materials for high specific energy absorption under static and dynamic loading, Acta Mater., 2016, vol. 116, pp. 14–28.

Yang, L., Harrysson, O., West, H., and Cormier, D., Compressive properties of Ti6Al4V auxetic mesh structures made by electron beam melting, Acta Mater., 2012, vol. 60, no. 8, pp. 3370–3379.

Van Bael, S., Chai, Y.C., Truscello, S., Moesen, M., Kerckhofs, G., van Oosterwyck, H., Kruth, J.-P., and Schrooten, J., The effect of pore geometry on the in vitro biological behavior of human periosteum-derived cells seeded on selective laser-melted Ti6Al4V bone scaffolds, Acta Biomater., 2012, vol. 8, no. 7, pp. 2824–2834.

Bartolo, P., Kruth, J.-P., Silva, J., Levy, G., Malshe, A., Rajurkar, K., Mitsuishi, M., Ciurana, J., and Leu, M., Biomedical production of implants by additive electro-chemical and physical processes, Cirp Ann.-Manuf. Technol., 2012, vol. 61, no. 2, pp. 635–655.

McKown, S., Shen, Y., Brookes, W.K., Sutcliffe, C.J., Cantwell, W.J., Langdon, G.S., Nurick, G.N., and Theobald, M.D., The quasi-static and blast loading response of lattice structures, Int. J. Impact Eng., 2008, vol. 35, no. 8, pp. 795–810.

Yan, C., Hao, L., Hussein, A., Wei, Q., and Shi, Y., Microstructural and surface modifications and hydroxyapatite coating of Ti6Al4V triply periodic minimal surface lattices fabricated by selective laser melting, Mater. Sci. Eng. C, 2017, vol. 75, pp. 1515–1524.

Olakanmi, E.O., Cochrane, R.F., and Dalgarno, K.W., A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties, Prog. Mater. Sci., 2015, vol. 74, pp. 401–477.

Bergstrom, J.S., Mechanics of Solid Polymers: Theory and Computational Modeling, Amsterdam: William Andrew, Elsevier, 2015, p. 520.

Abueidda, D.W., Bakir, M., Abu Al-Rub, R.K.B., Jörgen, S., Sobh, N.A., and Jasiuk, I., Mechanical properties of 3D printed polymeric cellular materials with triply periodic minimal surface architectures, Mater.Des., 2017, vol. 122, pp. 255–267.

Bergström, J., PolyUMod User’s Manual, Needham, MA: Veryst Engineering, 2009, p. 7.

Abou-Ali, A.M., Al-Ketan, O., Lee, D.-W., Rowshan, R., and Abu Al-Rub, R.K., Mechanical behavior of polymeric selective laser sintered ligament and sheet based lattices of triply periodic minimal surface architectures, Mater. Des., 2020, vol. 196, p. 109100.

Montazerian, H., Davoodi, E., Asadi-Eydivand, M., Kadkhodapour, J., and Solati-Hashjin, M., Porous scaffold internal architecture design based on minimal surfaces: A compromise between permeability and elastic properties, Mater. Des., 2017, vol. 126, pp. 98–114.

Funding

The study of the mechanical properties of structures and the development of topologies were financially supported by the Russian Science Foundation (project no. 20-73-10171). The development of a technique for modeling mechanical properties was carried out as part of a state assignment of the Institute of Chemistry of the Russian Academy of Sciences (state registration number of the topic, AAAA-A19-119022290092-5).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Arsentiev, M.Y., Sysoev, E.I. & Balabanov, S.V. A Study of the Mechanical Properties of Materials with the Tpmes Topology by Computer Simulation. Glass Phys Chem 47, 496–501 (2021). https://doi.org/10.1134/S1087659621050047

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1087659621050047