Abstract

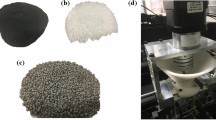

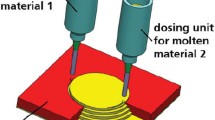

The paper proposes the design of a 3D printer that prints with a wax slip based on corundum powders. To activate the sintering of ceramics, the corundum grains are preliminarily clad with a two-layer shell of manganese and titanium compounds Al2O3–MnAl2O4–TiO2, which allows reducing the sintering temperature to 1400°C compared to pure corundum and ensures an even distribution of the sintering additive.

Similar content being viewed by others

REFERENCES

Shevchenko, V.Ya., Sychev, M.M., Lapshin, A.E., and Lebedev, L.A., Ceramic materials with the triply periodic minimal surface for constructions functioning under conditions of extreme loads, Glass Phys. Chem., 2017, vol. 43, no. 6, pp. 605–607.

Geiger, M., Greul, M., Sindel, M., and Steger, W., Multiphase jet solidification—a new process towards metal prototypes and a new data interface, in Proceedings of the Solid Freeform Fabrication Symposium, Univ. of Texas, Austin, TX, 1994, pp. 9–16.

3D-printer LUTUM. https://3dprinter.ua/glinyanyiy-3d-printer-lutum/. Accessed 2015.

Joris, P., Investment Casting and 3D-Printing: BFFs. https://3dprint.com/185785/ investment-casting-and-3dp/. Accessed 2017.

Tolochko, N.K., Andrushevich, A.A., Vasilevskii, P.N., and Chugaev, P.S., Application of 3D-printing extrusion technology in foundry production, Lit’e Metall., 2018, no. 4 (93), 139–143.

Bogdanov, S.P., Garshin, A.P., and Sychev, M.M., Armored ceramics based on corundum powders ‘core–shell’, in Sbornik dokladov 11go Mezhdunarodnogo simpoziuma Poroshkovaya metallurgiya: Inzheneriya poverkhnosti, novye poroshkovye kompozitsionnye materialy. Svarka (Proceedings of the International Symposium on Powder Metallurgy: Surface Engineering, New Powder Composite Materials. Welding, April 10–12, 2019), Minsk, 2019, part 1, pp. 424–430.

Bogdanov, S.P., Preparation of coatings on powders by the iodide transport method, Glass Phys. Chem., 2011, vol. 37, no. 2, pp. 172–178.

Bogdanov, S.P., Iodine transport method for obtaining coatings on powders, Izv. SPbGTI(TU), 2012, no. 16 (42), pp. 24–28.

Funding

The study was supported by a grant from the Russian Science Foundation (project no. 20-13-00054).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare to have no conflict of interest.

Rights and permissions

About this article

Cite this article

Bogdanov, S.P., Dolgin, A.S. & Makagon, A.I. 3D-Printing with the Paste Based on Corundum Powders’ Core Shell. Glass Phys Chem 46, 650–652 (2020). https://doi.org/10.1134/S108765962006005X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S108765962006005X