Abstract

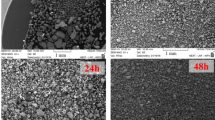

The possibilities of fabricating ceramics from the nanodispersed powder of niobium oxide have been investigated. Finely-grained (~100–150 nm), dense, and durable ceramics with a microhardness of up to 13 GPa have been created using the method of Spark Plasma Sintering (SPS).

Similar content being viewed by others

References

Moiseev, I.I., Klimov, D.M., Spitsyn, B.V., Kotov, Yu.A., Rusanov, A.I., Mikaelyan, A.L., Alfimov, M.V., and Rakhovskii, V.I., Discussion of the problems of nanotechnology, Vestn. Ross. Akad. Nauk, 2003, vol. 73, no. 7, pp. 429–449.

Zhou Xinzhang, Hulbert, D.M., Kuntz, J.D., Sadangi Rajendra, K., Shukla Vijay, Kear, B.H., and Mukherjee, A.K., Superplasticity of zirconia–alumina–spinel nanoceramic composite by spark plasma sintering of plasma sprayed powders, Mater. Sci. Eng., A, 2005, vol. 39, pp. 353–359.

Antsiferov, V.N. and Perel’man, V.E., Mekhanika protsessov pressovaniya poroshkovykh i kompozitsionnykh materialov (Mechanics of the pressing processes of powder and composite materials), Moscow, 2001.

Fizikokhimiya ul’tradispersnykh system: Tezisy V Vserossiiskoi konferentsii (Physical Chemistry of Ultrafine Systems: Abstracts of Papers of V All-Russian Conf.), Petrunin, V.F., Ed., Moscow: Mosk. Inzh.-Fiz. Inst., 2000.

Nanoparticles, Nanostructures & Nanocomposites: Proc. Topical Meeting of the European Ceramics Society, St. Petersburg: VVM, 2004.

Nanostructures: Physics and Technology: Proc. 16th International Symp., St. Petersburg: Ioffe Inst., 2007.

Lysenko, V.I., Ceramics from zinc oxide nanopowder: Preparation, structure, and properties, Nanoindustriya, 2013, no. 1, pp. 38–40.

Bardakhanov, S.P., Lysenko, V.I., Nomoev, A.V., and Trufanov, D.Yu., Ceramics prepared from silicon dioxide nanopowders, Glass Phys. Chem., 2008, vol. 34, no. 4, pp. 512–514.

Bardakhanov, S.P., Lysenko, V.I., Malov, A.N., Maslov, N.A., and Nomoev, A.V., Sructure and properties of ceramics based on nanopowders of gadolinium oxide and yttrium oxide, Fiz. Mezomekh., 2008, vol. 11, no. 5, pp. 111–114.

Bardakhanov, S.P., Lysenko, V.I., Nomoev, A.V., and Trufanov, D.Yu., Ceramics from nanopowders and its properties, Glass Ceram., 2008, vol. 65, no. 11, pp. 429–433.

Bardakhanov, S.P., Lysenko, V.I., Nomoev, A.V., Trufanov, D.Yu., and Fokin, A.V., Production of ceramic from copper oxide nanopowder and its properties, Vopr. Materialoved., 2010, no. 3.

Bardakhanov, S.P., Kim, A.V., Lysenko, V.I., Nomoev, A.V., Trufanov, D.Yu., Buyantuev, M.D., and Bazarova, D.Zh., Properties of ceramics prepared from nanopowders, Inorg. Mater., 2009, vol. 45, no. 3, pp. 335–339.

Bardakhanov, S.P., Kim, A.V., Lysenko, V.I., Maslov, N.A., Nomoev, A.V., Rozhin, I.A., and Trufanov, D.Yu., Structure and properties of nanoceramics based on alumina powder, Nanoindustriya, 2009, vol. 14, no. 2, pp. 22–25.

Bardakhanov, S.P., Emel’kin, V.A., Lysenko, V.I., Nomoev, A.V., and Trufanov, D.Yu., Preparation and properties of ceramics from a zirconia nanopowder, Glass Phys. Chem., 2009, vol. 35, no. 5, pp. 538–540.

Lysenko, V.I., Anisimov, A.G, Mali, V.I., and Emel’kin, V.A., Microhardness of ceramics produced from different alumina nanopowders by different techniques, Inorg. Mater., 2014, vol. 50, no. 5, pp. 537–540.

Lysenko, V.I., Mali, V.I., Anisimov, A.G., and Trufanov, D.Yu., Comparison of the characteristics of nanoporous ceramics created by SPS and by conventional method, Nanoindustriya, 2015, no. 2, pp. 70–77.

Palatnikov, M.N., Shcherbina, O.B., Sidorov, N.V., and Frolov, A.A., Physicochemical principles of heatresistant ceramic materials and containers for the hightemperature processing of high-purity niobium and tantalum compounds, in Tr. XXII Vserossiiskogo soveshchaniya po temperaturoustoichivym funktsional’nym pokrytiyam (Proc. 22nd All-Russian Meeting on Temperature Resistant Functional Coatings), St. Petersburg, 2012.

Palatnikov, M.N., Shcherbina, O.B., Sidorov, N.V., and Frolov, G.A., Physical and chemical principles of creating heat-resistant ceramic materials and containers for high-temperature processing of high-purity niobium and tantalum compounds. http://science.spb.ru/files/IzvetiyaTI/2012/16/Articles/24/files/assets/ downloads/publication.pdf

Palatnikov, M.N., Shcherbina, O.B., Efremov, V.V., Yanichev, A.A., Sidorov, N.V., and Pasichnyi, V.V., Structure and mechanical characteristics of ceramic Nb2O5 and Nb2(1 - y)Ta2y O5, Inorg. Mater., 2013, vol. 49, no. 9, pp. 909–915.

Palatnikov, M.N., Shcherbina, O.B., Efremov, V.V., and Sidorov, N.V., Synthesis,structure,and electrical and mechanical properties of Nb2(1 - y)Ta2y O5 ceramics, Inorg. Mater., 2015, vol. 51, no. 5, pp. 503–511.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.I. Lysenko, 2016, published in Fizika i Khimiya Stekla.

Rights and permissions

About this article

Cite this article

Lysenko, V.I. Creation and properties of ceramics from niobium oxide nanopowder. Glass Phys Chem 42, 522–524 (2016). https://doi.org/10.1134/S1087659616050096

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1087659616050096