Abstract

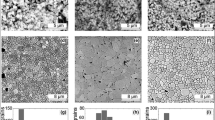

A translucent cubic yttria ceramic material doped by neodymium, namely, 1Nd: Y2O3, with particles of micrometer size (5–17 μm) and clearly defined boundaries is synthesized from nanopowders prepared by laser-induced evaporation with the use of magnetic pulsed compaction and vacuum sintering. Owing to the high activity of nanoparticles, the sintering is performed at temperatures below 1750°C without densifying additives. An increase in the sintering temperature to 900°C leads to an increase in the visual transparency of the ceramic materials and a decrease in the radiation attenuation coefficient. The samples of the translucent ceramics are characterized by rather large values of the microhardness (11.8 GPa) and the fracture toughness as compared to those of single crystals of the same composition. The fracture toughness of the ceramic material increases by a factor of approximately 2.5 with a decrease in the average crystallite size from 5.0 to 0.6 μm.

Similar content being viewed by others

References

Balkevich, V.L., Tekhnicheskaya keramika (Technical Ceramics), Moscow: Stroiizdat, 1984 [in Russian].

Lu, J., Lu, J., Murai, T., Takaichi, K., Uematsu, T., Ueda, K.I., Yagi, H., Yanagitani, T., and Kaminskii, A., Nd3+:Y2O3 Ceramic Laser, Jpn. J. Appl. Phys., 2001, vol. 40, pp. L1277–L1279.

Kaminskii, A.A., Lazernye kristally (Laser Crystals), Moscow: Nauka, 1975 [in Russian].

Kaminskii, A.A., Ueda, K., Eichler, H.J., Bagaev, S.N., Takaichi, K., Lu, J., Shirakawa, A., Yagi, H., and Yanagitani, T., Observation of Nonlinear Lasing χ(3)-Effects in Highly Transparent Nanocrystalline Y2O3 and Y3Al3O12 Ceramics, Laser Phys. Lett., 2004, vol. 1, pp. 6–11.

Lu, J., Ueda, K., Yagi, H., Yanagimi, T., Akiyama, Y., and Kaminskii, A., Neodymium Doped Yttrium Aluminum Garnet (Y3Al5O12) Nanocrystalline Ceramics—A New Generation of Solid State Laser and Optical Materials, J. Alloys Compd., 2002, vol. 341, pp. 220–225.

De With, G. and van Dijk, H.V.A., Translucent Y3Al5O12 Ceramics, Mater. Res. Bull., 1984, vol. 19, pp. 1669–1674.

Sekita, M., Haneda, H., Yanagitani, Y., and Shirasaki, S., Induced Emission Cross Section of Nd: Y3Al5O12 Ceramics, J. App. Phys., 1990, vol. 67, pp. 453–458.

Sekita, M., Haneda, H., Shirasaki, S., and Yanagitani, Y., Optical Spectra of Undoped and Rare-Earth (Pr, Nd, Eu, and Er) Doped Translucent Y3Al5O12 Ceramics, J. Appl. Phys., 1991, vol. 69, pp. 3709–4718.

Ikesue, A., Kinoshita, T., Kamata, K., and Yoshida, T., Fabrication and Optical Properties of High-Performance Polycrystalline Nd: YAG Ceramics for Solid-State Lasers, J. Am. Ceram. Soc., 1995, vol. 78, pp. 1033–1040.

Hahn, H., Microstructure and Properties of Nanostructured Oxides, Nanostruct. Mater., 1993, vol. 2, pp. 251–258.

He, Y.J., Winnubst, A.J.A., Verweij, H., and Burggraaf, A.J., Sinter Forging of Zirconia Toughened Alumina, J. Mater. Sci., 1994, no. 29, pp. 6505–6512.

Greskovich, C. and Woods, K.N., Fabrication of Transparent ThO2-Doped Y2O3, Am. Ceram. Soc. Bull., 1973, vol. 52, pp. 473–478.

Lukin, E.S., Efimovskaya, T.V., Belyakov, A.V., Tarasovskii, V.P., and Pshechenkov, P.A., Sintering and Formation of Microstructure of Translucent Polycrystalline Oxide Ceramics, Khim. Khim. Tekhnol. Silikat. Mater., 1983, no. 128, pp. 47–54.

Lukin, E.S., Modern High-Density Oxide Ceramics with Controlled Microstructure, Ogneupory, 1978, no. 4, pp. 2–13.

Ikegami, T., Li, J.-G., and Mori, T., Fabrication of Transparent Yttria Ceramics by the Low-Temperature Synthesis of Yttrium Hydroxide, J. Am. Ceram. Soc., 2002, vol. 85, no. 7, pp. 1725–1729.

Mouzon, J., Synthesis of Yb:Y2O3 Nanoparticles and Fabrication of Transparent Polycrystalline Yttria Ceramics, PhD Thesis, Lulea University of Technology, 2005.

Solomonov, V.I., Rasuleva, A.V., Osipov, V.V., and Ivanov, M.G., The Luminescent Investigation of Laser Nanomaterials Nd: Y2O3 and Nd: YAG, Proceedings of E-MRS 2005 Fall Meeting, Warsaw, Poland, Warsaw, 2005, p. 230.

Osipov, V.V., Ivanov, M.G., Lisenkov, V.V., and Platonov, V.V., High-Efficiency Pulse-Periodic CO2 Laser LAERT for Engineering Applications, Kvantovaya Elektron. (Moscow), 2002, vol. 32, no. 3, pp. 253–259.

Kotov, Yu.A., Osipov, V.V., Ivanov, M.G., Samatov, O.M., Platonov, V.V., Azarkevich, E.I., Murzakaev, A.M., and Medvedev, A.I., Properties of Oxide Nanopowders Prepared by Target Evaporation with a Pulse-Periodic CO2, Laser Tech. Phys., 2002, vol. 47, no. 11, pp. 1420–1426.

Ivanov, V., Paranin, S., and Nozdrin, A., Principles of Pulsed Compaction of Ceramic Nano-Sized Powders, Key Eng. Mater., 1997, vols. 132–136, pp. 440–403.

Ivanov, V.V., Paranin, S.N., Vikhrev, A.N., and Nozdrin, A.A., Efficiency of Dynamic Methods for Compacting Nanopowders, Materialovedenie, 1997, no. 5, pp. 49–55.

Dong, S., Beake, B.D., Parkinson, R., Xu, B., Hu, Z., and Bell, T., Determination of Hardness and Young’s Modulus of Brush Plated Nano-Al2O3/Ni Composite Coating by Nanoindentation Testing, Surface Eng., 2003, vol. 19, no. 3, pp. 195–199.

Kaminskii, A.A., Akchurin, M.Sh., Gainutdinov, R.I., Takaichi, K., Shirakava, A., Yagi, Ch., Yanagitani, T., and Ueda, K., Microhardness and Fracture Toughness of Y2O3-and Y3Al5O12-Based Nanocrystalline Laser Ceramics, Kristallografiya, 2005, vol. 50, no. 5, pp. 935–939 [Crystallogr. Rep. (Engl. transl.), 2005, vol. 50, no. 5, pp. 869–873].

Ander, H., Lehmann, J., and Ziegler, G., Improved Characterization of Ceramic Powder Surfaces—A Comparison of Different FTIR-Spectroscopy Methods, Key Eng. Mater., 1997, vols. 132–136, pp. 271–276.

Monterra, C. and Magnacca, G., A Case Study: Surface Chemistry and Structure of Catalytic Aluminas, as Studied by Vibrational Spectroscopy of Adsorbed Species, Catal. Today, 1996, vol. 27, pp. 497–532.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.V. Ivanov, A.S. Kaigorodov, V.R. Khrustov, V.V. Osipov, A.I. Medvedev, A.M. Murzakaev, A.N. Orlov, 2007, published in Fizika i Khimiya Stekla.

Rights and permissions

About this article

Cite this article

Ivanov, V.V., Kaigorodov, A.S., Khrustov, V.R. et al. Properties of the translucent ceramics Nd: Y2O3 prepared by pulsed compaction and sintering of weakly aggregated nanopowders. Glass Phys Chem 33, 387–393 (2007). https://doi.org/10.1134/S108765960704013X

Issue Date:

DOI: https://doi.org/10.1134/S108765960704013X