Abstract

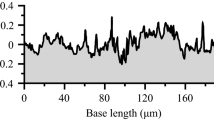

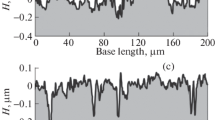

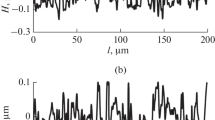

Procedures were suggested for preparing ohmic contacts by electroless Ni plating onto the surface of samples of thermoelectric materials based on bismuth and antimony chalcogenides. Nickel was deposited directly onto the sample surface and onto a Ni sublayer formed by ion plasma sputtering on the sample surface. The properties of the contacts are influenced by the roughness of the surface of thermoelectric material samples, by solutions used for decapping this surface, by the composition of electrolytes for electroless Ni plating, and by the presence of a Ni sublayer sputtered onto the sample surface. The Ni films up to 25 μm thick, prepared by electroless plating, contained ≥96.73 wt % Ni. The resistivity of the films was ≤10.24 × 10–8 Ω m. The specific contact resistance was (1.50–2.86) × 10−9 Ω m2. The films obtained on thermoelectric material samples by Ni plating from a NaBH4-based electrolyte onto a Ni sublayer sputtered onto these samples showed the highest adhesion strength, 14.62–14.83 MPa.

Similar content being viewed by others

REFERENCES

Joshi, G., Mitchell, D., Ruedin, J., Hoover, K., Guzman, R., McAleer, M., Wood, L., and Savoy, S., J. Mater. Chem. C, 2019, vol. 7, no. 3, pp. 479–483. https://doi.org/10.1039/c8tc03147a

Shtern, M., Rogachev, M., Shtern, Y., Gromov, D., Kozlov, A., and Karavaev, I., J. Alloys Compd., 2021, vol. 852, pp. 156889-1–156889-10. https://doi.org/10.1016/j.jallcom.2020.156889

Feng, H., Zhang, L., Zhang, J., Gou, W., Zhong, S., Zhang, G., Geng, H., and Feng, J., Materials, 2021, vol. 13, no. 5, pp. 1130-1–1130-12. https://doi.org/10.3390/ma13051130

Chen, L., Mei, D., Wang, Y., and Li, Y., J. Alloys Compd., 2019, vol. 796, pp. 314–320. https://doi.org/10.1016/j.jallcom.2019.04.293

Sharma, P.A., Brumbach, M., Adams, D.P., Ihlefeld, J.F., Lima-Sharma, A.L., Chou, S., Sugar, J.D., Lu, P., Michael, J.R., and Ingersoll, D., AIP Adv., 2019, vol. 9, no. 1, pp. 015125-1–015125-10. https://doi.org/10.1063/1.5081818

Zhu, X., Cao, L., Zhu, W., and Deng, Y., Adv. Mater. Interfaces, 2018, vol. 5, no. 23, pp. 1801279-1–1801279-9. https://doi.org/10.1002/admi.201801279

Shtern, M.Yu., Karavaev, I.S., Shtern, Y.I., Kozlov, A.O., and Rogachev, M.S., Semiconductors, 2019, vol. 53, no. 13, pp. 1848–1852. https://doi.org/10.1134/S1063782619130177

Kashi, S., Keshavarz, M.K., Vasilevskiy, D., Masut, R.A., and Turenne, S., J. Electron. Mater., 2012, vol. 41, no. 6, pp. 1227–1231. https://doi.org/10.1007/s11664-011-1895-3

Shtern, M., Rogachev, M., Shtern, Y., Sherchenkov, A., Babich, A., Korchagin, E., and Nikulin, D., J. Alloys Compd., 2021, vol. 877, pp. 160328-1–160328-13. https://doi.org/10.1016/j.jallcom.2021.160328

Shtern, M.Yu., Karavaev, I.S., Rogachev, M.S., Shtern, Yu.I., Mustafoev, B.R., Korchagin, E.P., and Kozlov, A.O., Fiz. Tekh. Poluprovodn., 2022, vol. 1, pp. 31–37. https://doi.org/10.21883/FTP.2022.01.51808.24

Sviridov, V.V., Khimicheskoe osazhdenie metallov is vodnykh rastvorov (Electroless Metal Plating from Aqueous Solutions), Minsk: Universitet, 1987, pp. 7–10.

Handbook of Chemistry and Physics, Lide, D.R., Ed., Boca Raton: CRC, 2003, 84th ed., p. 1989.

Sudagar, J., Lian, J., and Sha, W., J. Alloys Compd., 2013, vol. 571, pp. 183–204. https://doi.org/10.1016/j.jallcom.2013.03.107

Surface and Interface Science, Wandelt, K., Ed., Weinheim: Wiley–VCH, .

Funding

The study was supported by the Russian Science Foundation (project no. 20-19-00494).

Author information

Authors and Affiliations

Contributions

E.P. Korchagin: electroless deposition of Ni films and optimization of electrolyte solutions; M.Yu. Shtern: determination of the resistivity of the Ni films and of the contact resistance of the material–nickel contact structure; I.N. Petukhov: determination of the conditions and electrolyte compositions for electroless deposition of the films; Yu.I. Shtern: determination of the composition of the deposited films; M.S. Rogachev: study of the film surface roughness; A.O. Kozlov: determination of the conditions and ion plasma sputtering of Ni films; B.R.U. Mustafoev: measurement of the adhesion strength; A.A. Dedkova: examination of the surface morphology.

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated from Zhurnal Prikladnoi Khimii, No. 4, pp. 475–482, March, 2022 https://doi.org/10.31857/S0044461822040089

Rights and permissions

About this article

Cite this article

Korchagin, E.P., Shtern, M.Y., Petukhov, I.N. et al. Formation and Properties of Nickel Contacts to Thermoelectric Materials Based on Bismuth and Antimony Chalcogenides. Russ J Appl Chem 95, 536–543 (2022). https://doi.org/10.1134/S1070427222040097

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1070427222040097