Abstract

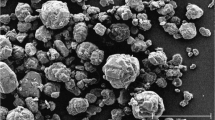

Barium aluminate BaAl2O4 of spinel structure was prepared by hydrothermal treatment at 150°С of a suspension of a gibbsite thermal activation product in an aqueous barium nitrate solution, followed by heat treatment of the precursors obtained. The product composition was studied by X-ray diffraction, thermal, microscopic, adsorption, and chemical analysis methods. Heat treatment of the hydrothermal reaction products at 850°С leads to the formation of single-phase barium aluminate BaAl2O4 with the specific surface area of ~50 m2 g–1 in the form of disk-shaped porous particles forming aggregates. The surface of BaAl2O4 particles is enriched in barium cations, which are relatively uniformly distributed over particles. The procedure allows reduction of the amount of the starting reactants and of the number of preparation steps, and also minimization or complete exclusion of the wash water formation.

Similar content being viewed by others

REFERENCES

Zhu, Z., Liu, F., and Zhang, W., Mater. Res. Bull., 2015, vol. 64, pp. 68–75. https://doi.org/10.1016/j.materresbull.2014.12.026

Li, S., Wang, W., Chen, Y., Zhang, L., Guo, J., and Gong, M., Catal. Commun., 2009, vol. 10, pp. 1048–1051. https://doi.org/10.1016/j.catcom.2008.12.064

Wako, A.H., Dejene, F.B., and Swart, H.C., J. Rare Earths, 2014, vol. 32, pp. 806–811. https://doi.org/10.1016/S1002-0721(14)60145-9

Maphiri, V.M., Mhlongo, M.R., Hlatshwayo, T.T., Motaung, T.E., Koao, L.F., and Motloung, S.V., Opt. Mater., 2020, vol. 109, ID 110244. https://doi.org/10.1016/j.optmat.2020.110244

Kim, D.H., Chin, Y.H., Kwak, J.H., Szanyi, J., and Peden, Ch.H.F., Catal. Lett., 2005, vol. 105, pp. 259–268. https://doi.org/10.1007/s10562-005-8700-y

Yadan, M. and Sharma, Y.C., Energy Conv. Manag., 2019, vol. 198, ID 111795. https://doi.org/10.1016/j.enconman.2019.111795

Mohapatra, A., Pattanaik, D.P., Anand, S., and Das, R.P., Ceram. Int., 2007, vol. 33, pp. 531–535. https://doi.org/10.1016/j.ceramint.2005.10.019

Rodehorst, U., Carpenter, M.A., Marion, S., and Henderson, C.M.B., Mineral. Mag., 2003, vol. 67, pp. 989–1013. https://doi.org/10.1180/0026461036750139

Chen, G.H. and Niu, D., J. Alloys Compd., 2006, vol. 413, pp. 319–322. https://doi.org/10.1016/j.jallcom.2005.07.001

Abakumov, A.M., Lebedev, O.I., Nistor, L., Tendeloo, G.V., and Amelinckx, S., Phase Trans., 2000, vol. 71, pp. 143–160. https://doi.org/10.1080/01411590008224545

Zhuzhgov, A.V., Kruglyakov, V.Yu., Suprun, E.A., Protsenko, R.S., and Isupova, L.A., Russ. J. Appl. Chem., 2021, vol. 94, no. 2, pp. 152–161. https://doi.org/10.1134/S107042722102004X

Bocanegra, S.A., Guerrero-Ruiz, А., Scelza, O.A., and de Miguel, С.Р., Catal. Ind., 2013, vol. 5, pp. 61–73. https://doi.org/10.1134/S2070050413010030

Belskaya, O.B., Stepanova, L.N., Gulyaeva, T.I., Golinskii, D.V., Belyi, A.S., and Likholobov, V.A., Kinet. Catal., 2015, vol. 56, no. 5, pp. 655–662. https://doi.org/10.1134/S0023158415050018

Patent RU 2264589, Publ. 2005.

Tanashev, Yu.Yu., Moroz, E.M., Isupova, L.A., Ivanova, A.S., Litvak, G.S., Amosov, Yu.I., Rudina, N.A., Shmakov, A.N., Stepanov, A.G., Kharina, I.V., Kul’ko, E.V., Danilevich, V.V., Balashov, V.A., Kruglyakov, V.Yu., Zolotarskii, I.A., and Parmon, V.N., Kinet. Catal., 2007, vol. 48, no. 1, pp. 153–161. https://doi.org/10.1134/S002315840701020X

Danilevich, V.V., Klimov, O.V., Nadeina, K.A., Gerasimov, E.Yu., Cherepanova, S.V., Vatutina, Yu.V., and Noskov, A.S., Superlat. Microstruct., 2018, vol. 120, pp. 148–160. https://doi.org/10.18412/1816-0387-2021-6-368-381

Danilevich, V.V., Isupova, L.A., and Parmon, V.N., Clean. Eng. Techn., 2021, vol. 3, ID 100118. https://doi.org/10.1016/j.clet.2021.100118

Buyanov, R.A. and Krivoruchko, O.P., Kinet. Katal., 1976, vol. 17, no. 3, pp. 765–775.

Ansaree, Md.J. and Upadhyay, S., Proc. Appl. Ceram., 2015, vol. 9, pp. 181–185. https://doi.org/10.2298/PAC1504181A

Funding

The study was performed within the framework of the government assignment for the Boreskov Institute of Catalysis, Siberian Branch, Russian Academy of Sciences (grant no. 0239-2021-0004).

Author information

Authors and Affiliations

Contributions

A.V. Zhuzhgov and V.Yu. Kruglyakov: development of the experimental procedure and participation in the sample preparation, analysis of the results, and manuscript preparation; E.A. Suprun: electron microscopic examination of the samples; L.A. Isupova: significant contribution to the idea and design of the study, to the data interpretation, and to the final manuscript preparation.

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated from Zhurnal Prikladnoi Khimii, No. 4, pp. 450–457, March, 2022 https://doi.org/10.31857/S0044461822040053

Rights and permissions

About this article

Cite this article

Zhuzhgov, A.V., Kruglyakov, V.Y., Suprun, E.A. et al. Synthesis of Barium Aluminate of Disk-Shaped Morphology Using the Product of Centrifugal Thermal Activation of Gibbsite. Russ J Appl Chem 95, 512–518 (2022). https://doi.org/10.1134/S1070427222040061

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1070427222040061