Abstract

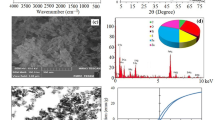

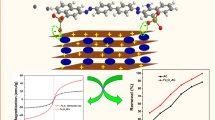

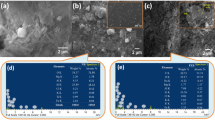

Magnetic nanoparticles and clay minerals combine to form a class of advanced nanocomposites that would possess exceptional adsorption, magnetism, and stability. In this work, an environmentally friendly nanocomposite was successfully fabricated by functionalizing natural clay. Bentonite сlay/meghemite nanocomposite was synthesized by the co-precipitation method and used to Methyl Orange pollutant removal as a toxic anionic dye from aqueous solutions. Physical and structural characteristics of the synthesized adsorbent were assessed using different techniques including Fourier transform infrared spectrometer, scanning electron microscopy, vibrating sample magnetometry, and X-ray diffraction. The saturation magnetization of maghemite and bentonite/maghemite nanocomposite are 50.9 and 28.5 emu g–1, respectively. The average size of the synthesized maghemite nanoparticles calculated by the Scherer equation was 16.60 nm. Different kinetic and thermodynamic models and isotherms of the adsorption process were also investigated. The adsorption capacity became equilibrium after 120 min. The consistency of the adsorption process with the pseudo-second-order kinetic model was confirmed by studying its kinetic data. Investigating the equilibrium isotherm data at different temperatures showed better compatibility with the Freundlich model. The negative values of ΔG and positive values of ΔH obtained from adsorption thermodynamic study revealed that Methyl Orange adsorption from aqueous samples is spontaneous and endothermic. The optimal parameters for Methyl Orange removal by synthesized adsorbent were determined by MINITAB 17 under response surface methodology (RSM). The maximum adsorption capacity of dye adsorption of 56.79 mg g–1 was obtained under optimum conditions of pH = 4, adsorbent dose of 1 g L–1 and dye concentration of 90 mg L–1.

Similar content being viewed by others

REFERENCES

Gupta, V.K. and Saleh, T.A., Env. Sci. & Pollution Res., 2013, vol. 20, no. 5, pp. 2828–2843. https://doi.org/10.1007/S11356-013-1524-1

Paul, J., et al., Appl. Radiat. & Isot., 2011, vol. 69, no. 7, pp. 982–987. https://doi.org/10.1016/j.apradiso.2011.03.009

Javanbakht, V., Alavi, S.A., and Zilouei, H., Water Sci. & Technol., 2014, vol. 69, no. 9, p. 1775. https://doi.org/10.2166/wst.2013.718

Javanbakht, V. and Ghoreishi, S.M., Adsorption Science & Technology, 2017, vol. 35, nos. 1–2, pp. 241–260. https://doi.org/10.1177/0263617416674474

Sabouri, M.R., Et Al., Process Safety and Environmental Protection, 2019, vol. 126, pp. 182–192. https://doi.org/10.1016/j.psep.2019.04.006

Saravanan, R., et al., Colloid & Interface Science, 2015, vol. 452, pp. 126-133. https://doi.org/10.1016/j.jcis.2015.04.035

Javanbakht, V., et al., Powder Technology, 2016, vol. 302, pp. 372-383. https://doi.org/10.1016/j.powtec.2016.08.069

Al-Kdasi, A., et al., Global Nest, The Int. J, 2004, vol. 6, no. 3, pp. 222–230.

Chen, S., et al., Desalination, 2010, vol. 2521–3, pp. 149–156. https://doi.org/10.1016/j.desal.2009.10.010

Ofomaja, A.E. and Ho, Y.-S., Bioresource Technology, 2008, vol. 99, no. 13, pp. 5411–5417. https://doi.org/10.1016/j.biortech.2007.11.018

Royer, B., et al., Hazardous Materials, 2009, vol. 164, nos. 2–3, pp. 1213–1222. https://doi.org/10.1016/j.jhazmat.2008.09.028

Brookstein, D.S., Dermatologic Clinics, 2009, vol. 27, no. 3, pp. 309–322. https://doi.org/10.1016/j.det.2009.05.001

Carneiro, P.A., et al., Hazardous Materials, 2010, vol. 174, nos. 1–3, pp. 694–699. https://doi.org/10.1016/j.jhazmat.2009.09.106

Mehrabi, M. and Javanbakht, V, Materials Science, Materials In Electronics, 2018, vol. 29, no. 12, pp. 9908–9919. https://doi.org/10.1007/S10854-018-9033-0

Bayat, M., et al., International Journal of Biological Macromolecules, 2018, vol. 116, pp. 607–619. https://doi.org/10.1016/J.Ijbiomac.2018.05.012

Erfani, M. and Javanbakht, V., International Journal of Biological Macromolecules, 2018, vol. 114, pp. 244–255. https://doi.org/10.1016/J.Ijbiomac.2018.03.003

Mirzaei, S. and Javanbakht, V., International Journal of Biological Macromolecules, 2019, vol. 134, pp. 1187–1204. https://doi.org/10.1016/j.ijbiomac.2019.05.119

Haque, E., et al., Hazardous Materials, 2011, vol. 185, no. 1, pp. 507–511. https://doi.org/10.1016/j.jhazmat.2010.09.035

Vaez, Z. and Javanbakht, V., Photochemistry & Photobiology A, Chemistry, 2019, vol. 388, p. 112064. https://doi.org/10.1016/j.jphotochem.2019.112064

Chen, Z.-X., et al., Colloid and Interface Science, 2011, vol. 363, no. 2, pp. 601–607. https://doi.org/10.1016/j.jcis.2011.07.057

Azizian, S., et al., Chemical Engineering, 2009, vol. 146, no. 1, pp. 36–41. https://doi.org/10.1016/j.cej.2008.05.024

Rahpeima, S., et al., Inorganic and Organometallic Polymers and Materials, 2018, vol. 28, no. 1, pp. 195–211. https://doi.org/10.1007/S10904-017-0688-4

Demirbas, E., et al., Bioresource Technology, 2008, vol. 99, no. 13, pp. 5368–5373. https://doi.org/10.1016/j.biortech.2007.11.019

Keyvani, F., et al., Solid State Sciences, 2018, Vol. 83, pp. 31–42. https://doi.org/10.1016/j.solidstatesciences.2018.06.007

Alver, E. and Metin, A.Ü. Chemical Engineering, 2012, vol. 200, pp. 59–67. https://doi.org/10.1016/j.cej.2012.06.038

Wang, X.S., et al., Hazardous Materials, 2008. Vol. 157, nos. 2–3, pp. 374–385. https://doi.org/10.1016/j.jhazmat.2008.01.004

Rosa, S., et al., Hazardous Materials, 2008, vol. 155, nos. 1–2, pp. 253–260. https://doi.org/10.1016/j.jhazmat.2007.11.059

Tanabtabzadeh, M.S., et al., Waste and Biomass Valorization, 2019, vol. 10, no. 3, pp. 641–653. https://doi.org/10.1007/S12649-017-0086-8

Liu, Y., et al., Chemical Engineering, 2013, vol. 218, pp. 46–54. https://doi.org/10.1016/j.cej.2012.12.027

Javanbakht, V., et al., Protection of Metals and Physical Chemistry of Surfaces, 2017, vol. 53, no. 4, pp. 693–702. https://doi.org/10.1134/S2070205117040086

Javanbakht, V., et al., Chemical and Pharmaceutical Research, 2016, vol. 8, no. 4, pp. 846–852.

Demirbas, A., Hazardous Materials, 2009, vol. 167, no. 1, pp. 1–9. https://doi.org/10.1016/j.jhazmat.2008.12.114

Mallakpour, S. and Hatami, M., Designed Monomers and Polymers, 2011, vol. 14, no. 5, pp. 461–473. https://doi.org/10.1163/138577211X587654

Oliveira, L.C., et al., Carbon, 2002, vol. 40, no. 12, pp. 2177–2183. https://doi.org/10.1016/S0008-62230200076-3

Sareban, Z. and Javanbakht, V., Korean Journal of Chemical Engineering, 2017, vol. 34, no. 11, pp. 2886–2900. https://doi.org/10.1007/S11814-017-0216-9

Aeenjan, F. and Javanbakht, V., Research On Chemical Intermediates, 2018, vol. 44, no. 3, pp. 1459–1483. https://doi.org/10.1007/S11164-017-3179-X

Gnanaprakash, G., et al., Materials Chemistry and Physics, 2007, vol. 103, no. 1, pp. 168–175. https://doi.org/10.1016/j.matchemphys.2007.02.011

Lu, A.H., et al., Angewandte Chemie International Edition, 2007, vol. 46, no. 8, pp. 1222–1244. https://doi.org/10.1002/anie.200602866

Chen, L., et al., Applied Clay Science, 2016, vol. 127, pp. 143–163. https://doi.org/10.1016/j.clay.2016.04.009

Rechendorff, K., et al., Langmuir, 2006, vol. 22, no. 26, pp. 10885–10888. https://doi.org/10.1021/la0621923

Özcan, A.S. and Özcan, A., Colloid and Interface Science, 2004, vol. 276, no. 1, pp. 39–46. https://doi.org/10.1016/j.jcis.2004.03.043

Darezereshki, E., et al., Materials Science In Semiconductor Processing, 2013, vol. 16, no. 1, pp. 221–225. https://doi.org/10.1016/j.mssp.2012.08.007

Tan, Y., et al., Chemical Engineering, 2012, vol. 191, pp. 104–111. https://doi.org/10.1016/j.cej.2012.02.075

Xie, M., et al., Alloys and Compounds, 2015, vol. 647, pp. 892–905. https://doi.org/10.1016/j.jallcom.2015.06.065

Zhao, G., et al., The Open Colloid Science, 2010, vol. 4, p. 1. https://doi.org/10.2174/1876530001104010019

Foo, K. and Hameed, B., Chemical Engineering, 2010, vol. 156, no. 1, pp. 2–10. https://doi.org/10.1016/j.cej.2009.09.013

Gautam, R.K., et al., Molecular Liquids, 2015, vol. 204, pp. 60–69. https://doi.org/10.1016/J.Molliq.2015.01.038

Bayramoğlu, G. and Arica, M.Y., Chemical Engineering, 2008, vol. 139, no. 1, pp. 20–28. https://doi.org/10.1016/j.cej.2007.07.068

Ma, J., et al., ACS Applied Materials & Interfaces, 2012, vol. 4, no. 11, pp. 5749–5760. https://doi.org/10.1021/am301053m

Hao, Y.-M., et al., Hazardous Materials, 2010, vol. 184, no. 1, pp. 392–399. https://doi.org/10.1016/j.jhazmat.2010.08.048

Chang, Y.C. and Chen, D.H., Macromolecular Bioscience, 2005, vol. 5, no. 3, pp. 254–261. https://doi.org/10.1002/Mabi.200400153

Aksu, Z. and Gönen, F., Separation & Purification Technology, 2006, vol. 49, no. 3, pp. 205–216. https://doi.org/10.1016/j.seppur.2005.09.014

Can, M.Y., et al., Bioresource Technology, 2006, vol. 97, no. 14, pp. 1761–1765. https://doi.org/10.1016/j.biortech.2005.07.017

Ghorbani, F., et al., Chemical Engineering, 2008, vol. 145, no. 2, pp. 267–275. https://doi.org/10.1016/j.cej.2008.04.028

Ahmed, M., et al., Materials Science & Engineering, B, 2013, vol. 178, no. 10, pp. 744–751. https://doi.org/10.1016/j.mseb.2013.03.011

Dinu, M.V. and Dragan, E.S., Chemical Engineering, 2010, vol. 160, no. 1, pp. 157–163. https://doi.org/10.1016/j.cej.2010.03.029

Wang, L. and Wang, A., Bioresource Technology, 2008, vol. 99, no. 5, pp. 1403–1408. https://doi.org/10.1016/j.biortech.2007.01.063

Zhu, H., et al., Applied Surface Science, 2011, vol. 258, no. 4, pp. 1337–1344. https://doi.org/10.1016/j.apsusc.2011.09.045

Kamaru, A.A., et al., Desalination & Water Treatment, 2016, vol. 57, no. 40, pp. 18836–18850. https://doi.org/10.1080/19443994.2015.1095122

Shariati-Rad, M., et al., International Nano Letters, 2014, vol. 4, no. 4, pp. 91–101. https://doi.org/10.1007/S40089-014-0124-5

Fan, J., et al., Colloid and Interface Science, 2016, vol. 470, pp. 229–236. https://doi.org/10.1016/j.jcis.2016.02.045

Yang, H.-C., et al., Colloid and Interface Science, 2017, vol. 505, pp. 67–78. https://doi.org/10.1016/j.jcis.2017.05.075

Karthika, J. and Vishalakshi, B., International Journal of Biological Macromolecules, 2015, vol. 81, pp. 648–655. https://doi.org/10.1016/j.ijbiomac.2015.08.064

ACKNOWLEDGMENT

Financial support of this work by ACECR Institute of Higher Education (Isfahan Branch) is gratefully appreciated.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Rezaei, S., Rahpeima, S., Esmaili, J. et al. Optimization by Response Surface Methodology of the Adsorption of Anionic Dye on Superparamagnetic Clay/Maghemite Nanocomposite. Russ J Appl Chem 94, 533–548 (2021). https://doi.org/10.1134/S1070427221040145

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1070427221040145