Abstract

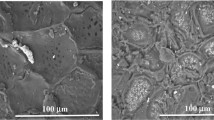

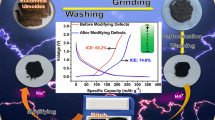

The possibility of using aspen bark modified with zinc and iron chlorides for preparing highly porous materials with specific properties was examined. The effect of the treatment temperature and modifiers on the structural and electrochemical parameters of the carbon-containing product was revealed. Carbonization of aspen bark modified with ZnCl2 yielded a material with the specific surface area of up to 1350 m2 g–1, containing a crystalline zinc oxide phase. The material obtained using a mixture of aspen bark with FеCl3 had the specific surface area of up to 300 m2 g–1 and contained magnetite and maghemite. Modification of the bark with zinc and iron chlorides simultaneously yielded a highly porous product with ferromagnetic properties. The apparent capacitance of the samples carbonized at 800°С was found to be 150–400 F g–1. The possibility of using these materials in electrochemical devices was suggested.

Similar content being viewed by others

REFERENCES

Soboleva, S.V., Chentsova, L.I., and Voronin, V.M., Pererabotka kory osiny s polucheniem biologicheski aktivnykh veshchestv i kormovykh produktov: monografiya (Processing of Aspen Bark with Preparation of Biologically Active Compounds and Forage Products: Monograph), Krasnoyarsk: Sib. Gos. Tekh. Univ., 2013.

Kharouk, V.I., Middleton, E.M., Spencer, S.L., Rock, B.N., and Williams, D.L., Water,Air Soil Pollut., 1995, vol. 82, pp. 483–497.

Pasztory, Z., Mohacsine, I.R., Gorbacheva, G., and Borcsok, Z., Bioresources, 2016, vol. 11, no. 3, pp. 7859–7888.

Soboleva, S.V. and Litovka, Yu.A., Khim. Rast. Syr’ya, 2011, vol. 2, pp. 83–86.

Marsh, H. and Rodriguez-Reinoso, F., Activated Carbon, Elsevier, 2006, pp. 3–536.

Tsyganova, S.I., Romanchenko, A.S., Fetisova, O.Yu., Mazurova, E.V., and Bondarenko, G.N., Zh. Sib. Fed. Univ., Khimiya, 2018, vol. 2, no. 11, pp. 281–290. https://doi.org/10.17516/1998-2836-0075

Tsyganova, S.I., J. Wood Sci. Technol., 2013, vol. 47, pp. 77–82. https://doi.org/10.1007/s00226-012-0490-y

Swarnalatha, S., Kumar, A.G., and Sekaran, G., J. Porous Mater., 2009, vol. 16, pp. 239–245. https://doi.org/10.1007/s10934-008-9192-0

Xu, C. and Strømme, M., Nanomaterials, 2019, vol. 9, no. 1:103, pp. 1–13. https://doi.org/10.3390/nano9010103

Peng, X., Zhang, L., Chen, Z., Zhong, L., Zhao, D., Chi, X., Zhao, X., Li, L., Lu, L., Leng, K., Liu, C., Liu, W., Tang, W., and Loh, K.P., Adv. Mater., 2019, vol. 31, pp. 1–7. https://doi.org/10.1002/adma.201900341

Zhang, J. and Zhang, W., Mater. Sci.(Medziagotyra), 2014, vol. 20, no. 4, pp. 474–478. https://doi.org/10.5755/j01.ms.20.4.6400

Mikova, N.M., Fetisova, O.Yu., Ivanov, I.P., Pavlenko, N.M., and Chesnokov, N.V., Khim. Rast. Syr’ya, 2017, vol. 4, pp. 53–64. https://doi.org/10.14258/jcprm.2017042018

Tsyganova, S.I., Romanchenko, A.S., Bondarenko, G.N., and Fetisova, O.Yu., Russ. J. Appl. Chem., 2018, vol. 91, no. 2, pp. 330−336. https://doi.org/10.1134/S1070427218020258

Erabee, I.K., Ahsan, A., Zularisam, A.W., Idrus, S., Daud, N.N.N., Arunkumar, T., Sathyamurthy, R., and Al-Rawajfeh, A.E., Eng. J., 2017, vol. 21, no. 5, pp. 1−15. https://doi.org/10.4186/ej.2017.21.5.1

Mohapatra, D., Parida, S., Badrayyana, S., and Singh, B.K., Appl. Mater. Today, 2017, vol. 7, pp. 212–221. https://doi.org/10.1016/j.apmt.2017.03.006

Wang, H., Yu, S., and Xu, B., Chem. Commun., 2016, vol. 52, no. 77, pp. 11512−11515. https://doi.org/10.1039/C6CC05911B

Guetteche, Y., Bordjiba, T., Bouguerne, B., Nabeti, Z., Mahmoudi, O., and Lemzademi, A., Int. J.Electrochem. Sci., 2017, vol. 12, pp. 1874–1884. https://doi.org/10.20964/2017.03.37

Borgohain, R., Li, J., Selegue, J.P., and Cheng, Y.-T., J. Phys. Chem. C, 2012, pp. 15068−15075. https://doi.org/10.1021/jp301642s

Banerjee, A., Gokhale, R., Bhatnagar, S., Jog, J., Bhardwaj, M., and Lefez, B., J. Mater. Chem., 2012, vol. 22, pp. 19694−9699. https://doi.org/10.1039/C2JM33798C

Reiner, T., Jantke, D., Marziale, A.N., Raba, A., and Eppinger, J., Chem. Open, 2013, vol. 2, pp. 50−54. https://doi.org/10.1002/open.201200044

Zhi, M., Xiang, C., Li, J., Li, M., and Wu, N., Nanoscale, 2013, vol. 5, pp. 72−88. https://doi.org/10.1039/C2NR32040A

Zhang, R.D.J., Li, J.Q.Z., Wang, C., and Chen, M., ACS Appl. Mater. Interfaces, 2018, vol. 10, no. 16, pp. 13470–13478. https://doi.org/10.1021/acsami.8b00353

Raghu, M., Nanostructured Arrays for Sensing and Energy Storage Applications, Doctoral Dissertation, Univ. of Kentucky, 2011. pp. 1–153.

Pandey, K.K., J. Appl. Polym. Sci., 1999, vol. 71, pp. 1969–1975. https://doi.org/10.1002/(SICI)1097-4628(19990321)71:12>1969::AID-APP6<3.0.CO;2-D

Tsyganova, S.I., Patrushev, V.V., Bondarenko, G.N., and Velikanov, A.M., Zh. Sib. Fed. Univ., Khimiya, 2011, vol. 4, no. 4, pp. 388−398.

Lufrano, F. and Staiti, P., Int. J. Electrochem. Sci., 2010, vol. 5, pp. 903–916.

ACKNOWLEDGMENTS

The authors are grateful to the Krasnoyarsk Regional Center for Shared Use, Siberian Branch, Russian Academy of Sciences, for the assistance in the study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tsyganova, S.I., Romanchenko, A.S., Fetisova, O.Y. et al. Preparation and Structural and Electrochemical Characteristics of a Carbon-Containing Material Based on Aspen Bark Modified with Zinc and Iron Chlorides. Russ J Appl Chem 93, 672–678 (2020). https://doi.org/10.1134/S1070427220050079

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1070427220050079