Abstract

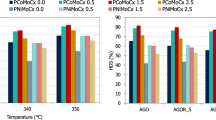

Behavior of the sulfide NiMo catalyst on an alumina support containing SAPO—11 silicoaluminophosphate (NiMo/SAP-Al2O3) in the hydroprocessing of a mixture of a straight run gas oil (SRGO) and rapeseed oil (RO) was studied under a pressure of 5.0 MPa and liquid hourly space velocity of 1.5 h−1. The effect of temperature on the properties of the products produced in the hydroprocessing of a mixture with 30 wt % RO and 70 wt % SRGO in the presence of the NiMo/SAP-Al2O3 catalyst and a double-bed catalytic system containing layer-by-layer loaded Mo/Al2O3 and NiMo/SAP-Al2O3 sulfide catalysts. It was found that the experimental conditions provide a full conversion of oxygen-containing compounds and reduction of the content of sulfur to less than 10 mg kg−1. Raising the temperature from 330 to 380°C leads to an increase in the conversion of alkanes formed due to the hydrodeoxygenation of rapeseed oil and to lowering of the cloud point of the hydroprocessing products by approximately 15°. Possible reasons for the differences in behavior between the systems under study: a high conversion of C17, C18 alkanes is reached in the presence of the NiMo/SAP-Al2O3 catalyst, whereas the double layer Mo/Al2O3 + NiMo/SAP-Al2O3 system provides a more effective course of the reactions in which aromatic hydrocarbons are hydrogenated.

Similar content being viewed by others

References

Fivga, A., Speranza, L.G., Branco, C.M., Ouadi, M., and Hornung, A., AIMS Energy, 2019, vol. 7, no. 1, pp. 46–76. https://doi.org/10.3934/energy.2019.1.46

Mittelbach, M., Eur. J. Lipid Sci. Technol., 2015, vol. 117, no. 11, pp. 1832–1846. https://doi.org/10.1002/ejlt.201500125

Yakovlev, V.A., Khromova, S.A., and Bukhtiyarov, V.I., Russ. Chem. Rev., 2011, vol. 80, no. 10, pp. 911–925. https://doi.org/10.1070/RC2011v080n10ABEH004182

Al-Sabawi, M. and Chen, J.W., Energy Fuels, 2012, vol. 26, no. 9, pp. 5373–5399. https://doi.org/10.1021/ef3006405

van Dyk, S., Su, J., McMillan, J.D., and Saddler, J., Biofuels Bioprod. Biorefin., 2019, vol. 13, no. 3, pp. 760–775. https://doi.org/10.1002/bbb.1974

Bezergianni, S., Dimitriadis, A., Kikhtyanin, O., and Kubicka, D., Prog. Energy Combust. Sci., vol. 68, pp. 29–64. https://doi.org/10.1016/j.pecs.2018.04.002

Toth, C., Sagi, D., and Hancsok, J., J. Cleaner Prod., 2016, vol. 111, pp. 42–50. https://doi.org/10.1016/j.jclepro.2015.07.152

Vlasova, E.N., Delii, I.V., Nuzhdin, A.L., Aleksandrov, P.V., Gerasimov, E.Yu., Aleshina, G.I., and Bukhtiyarova, G.A., Kinet. Catal., 2014, vol. 55, no. 4, pp. 480–490. https://doi.org/10.1134/s0023158414040144

Nikul’shin, P.A., Sal’nikov, V.A., Pimerzin, A.A., Eremina, Y.V., Koklyukhin, A.S., Tsvetkov, V.S., and Pimerzin, A.A., Petrol. Chem., 2016, vol. 56, no. 1, pp. 56–61. https://doi.org/10.1134/s0965544115080150

Bezergianni, S., Dimitriadis, A., and Meletidis, G., Fuel, 2014, vol. 125, pp. 129–136. https://doi.org/10.1016/j.fuel.2014.02.010

Vlasova, E.N., Deliy, I.V., Gerasimov, E.Yu., Aleksandrov, P.V., Nuzhdin, A.L., Aleshina, G.I., and Bukhtiyarova, G.A., Petrol. Chem., 2017, vol. 57, no. 12, pp. 1156–1160. https://doi.org/10.1134/S0965544117060263

Kubička, D. and Kaluža, L., Appl. Catal., A, 2010, vol. 372, pp. 199–208. https://doi.org/10.1016/j.apcata.2009.10.034

Donnis, B., Egeberg, R.G., Blom, P., and Knudsen, K.G., Top. Catal., 2009, vol. 52, no. 3, pp. 229–240. https://doi.org/10.1007/s11244-008-9159-z

Satyarthi, J.K., Chiranjeevi, T., Gokak, D.T., and Viswa-Nathan, P.S., Catal. Sci. Technol., 2013, vol. 3, pp. 70–80. https://doi.org/10.1039/c2cy20415k

Stanislaus, A., Marafi, A., and Rana, M., Catal. Today, 2010, vol. 153, nos. 1–2, pp. 1–68. https://doi.org/10.1016/j.cattod.2010.05.011

de Brimont, M.R., Dupont, C., Daudin, A., Geantet, C., and Raybaud, P., J. Catal., 2012, vol. 286, pp. 153–164. https://doi.org/10.1016/j.jcat.2011.10.022

Dupont, C., Lemeur, R., Daudin, A., and Raybaud, P., J. Catal., 2011, vol. 279, no. 2, pp. 276–286. https://doi.org/10.1016/j.jcat.2011.01.025

Deliy, I.V., Vlasova, E.N., Nuzhdin, A.L., Gerasimov, E.Yu., and Bukhtiyarova, G.A., RSC Adv., 2014, vol. 4, pp. 2242–2250. https://doi.org/10.1039/c3ra46164e

Simacek, P., Kubicka, D., Kubickova, I., Homola, F., Pospasil, M., and Chudoba, J., Fuel, 2011, vol. 90, pp. 2473–2479. https://doi.org/10.1016/j.fuel.2011.03.013

Rana, B.S., Kumar, R., Tiwari, R., Joshi, R.K., Garg, M.O., and Sinha, A.K., Biomass Bioenergy, 2013, vol. 56, pp. 43–52. https://doi.org/10.1016/j.biombioe.2013.04.029

Kumar, R., Rana, B.S., Tiwari, R., Verma, D., Kumar, R., Joshi, R.K., Garg, M.O., and Sinha, A.K., Green Chem., 2010, vol. 12, pp. 2232–2239. https://doi.org/10.1039/C0GC00204F

Sankaranarayanan, T.M., Banu, M., Pandurangan, A., and Sivasanker, S., Bioresour. Technol., 2011, vol. 102, no. 22, pp. 10717–10723. https://doi.org/10.1016/j.biortech.2011.08.127

Zhang, X., Guo, A., Wang, F., and Duang, X., Energy Fuels, 2010, vol. 24, no. 7, pp. 3772–3777. https://doi.org/10.1021/ef901373w

Xing, G.H., Liu, S.Y., Guan, Q.X., and Li, W., Catal. Today, 2019, vol. 330, pp. 109–116. https://doi.org/10.1016/j.cattod.2018.04.028

Li, T., Cheng, J., Huang, R., Yang, W., Zhou, J., and Cen, K., Int. J. Hydrogen Energy, 2016, vol. 41, no. 47, pp. 21883–21887. https://doi.org/10.1016/jijhydene.2016.09.013

Liu, Q., Zuo, H., Zhang, Q., Wang, T., and Ma, L., Chin. J. Catal., 2014, vol. 35, no. 5, pp. 748–756. https://doi.org/10.1016/S1872-2067(12)60710-4

Verma, D., Rana, B.S., Kumar, R., Sibi, M.G., and Sinha, A.K., Appl. Catal., A, 2015, vol. 490, pp. 108–116. https://doi.org/10.1016/j.apcata.2014.11.007

Nuzhdin, A.L., Bukhtiyarova, G.A., Porsin, A.A., Prosvirin, I.P., Deliy, I.V., Volodin, V.A., Gerasimov, E.Y., Vlasova, E.N., and Bukhtiyarov, V.I., Catalysts, 2019, vol. 9, p. 96. https://doi.org/10.3390/catal9010096

Anand, M., Farooqui, S.A., Kumar, R., Joshi, R., Kumar, R., Sibi, M.G., Singh, H., and Sinha, A.K., Fuel Process. Technol., 2016, vol. 151, pp. 50–58. https://doi.org/10.1016/j.fuproc.2016.05.028

Acknowledgments

The authors are grateful to E.Yu. Gerasimov for a TEM analysis of samples of the sulfide catalysts. The study was carried out on the equipment of the Collective Use Center “National center of research into catalysts.”

Funding

The study was financially supported by the Ministry of Science and Higher Education of the Russian Federation, project no. 14.575.21.0128, unique project identifier RFMEFI57517X0128.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors state that they have no conflict of interest to be disclosed in the present communication.

Additional information

Russian Text © The Author(s), 2019, published in Zhurnal Prikladnoi Khimii, 2019, Vol. 92, No. 13, pp. 1723–1731.

Rights and permissions

About this article

Cite this article

Porsin, A.A., Vlasova, E.N., Nuzhdin, A.L. et al. Co-Processing of Straight Run Gas Oil-Rapeseed Oil Mixture Using Sulfide NiMo Catalyst on Zeolite-Containing Support. Russ J Appl Chem 92, 1797–1804 (2019). https://doi.org/10.1134/S1070427219120228

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1070427219120228