Abstract

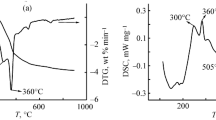

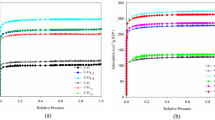

Method is suggested for obtaining biochar materials by treatment of a finely dispersed (≤0.1 mm) bark of aspen and(or) larch with a 40% formaldehyde solution and subsequent thermal activation of the activated bark. It was found that keeping the composite at a temperature of 50–80°C for three days makes the binding process complete. Further carbonization at temperatures of 350–900°C yields a biochar with bulk structure. The method of IR spectroscopy confirmed that the functional composition of bark changes under the action of a cross-linking agent and — CH2 — bonds are additionally formed. It was found that the larch bark containing lignins of predominantly G-type and condensed tannins is more suitable for obtaining porous biochar materials (with specific surface area of 94–161 m2 g−1) as compared with the aspen bark. The adsorption properties of biochar materials produced from the modified bark in removal of Cu(II) ions from aqueous solutions. It was found that, on being carbonized at 900°C, a sample of modified aspen bark can extract 122.9 to 220 mg g−1 of copper compounds on raising the sorption temperature from 25 to 45°C.

Similar content being viewed by others

References

Kuznetsov, B.N., Levdanskii, V.A., and Kuznetsova, S.A., Khimicheskieprodukty iz drevesnoi kory (Chemical Products from Wood Bark), Krasnoyarsk: Sib. Feder. Univ., 2012, pp. 51–103.

Ivanova, S.Z., Fedorova, T.E., Ivanova, N.V., Ostroukhova, L.A., Malkov, Yu.A., and Babkin, V.A., Khvoinye Boreal’n. Zony, 2003, no. 1, pp. 123–128.

Deineko, I.P. and Faustova, N.M., Khim. Rastit. Syr’ya, 2015, no. 1, pp. 51–62. https://doi.org/10.14258/jcprm.201501461

Tsvetkov, M.V and Salganskii, E.A., Russ. J. Appl. Chem., 2018, vol. 91, no. 7, pp. 1129–1136. https://doi.org/10.1134/S1070427218070108.

Pizzi, A., Tannins: Major Sources, Properties and Applications in Monomers, Polymers and Composites from Renewable Resources, Belgacem, M.N. and Gandini,A., Eds., Elsevier, 2008, pp. 179–199.

Varfolomeev, A.A., Sinegibskaya, A.D., Gogotov, A.F., Kanitskaya, L.V., and Rokhin, A.V., Khim. Rastit. Syr’ya, 2009, no. 3, pp. 11–16.

Grishechko, L.I., Amaral-Labat, G., Szczurek, A., Fierro, V., Kuznetsov, B.N., and Celzard, A., Micropor. Mesopor. Mater., 2013, vol. 168, pp. 19–29. https://doi.org/10.1016/j.micromeso.2012.09.024

Tejado, A., Peña, C., Labidi, J., Echeverria, J.M., and Mondragon, I., Bioresour. Technol., 2007, vol. 98, pp. 1655–1663. https://doi.org/10.1016/j.biortech.2006.05.042

Mikova, N.M., Grishechko, L.I., Skvortsova, G.P., and Kuznetsov, B.N., Russ. J. Bioorg. Chem., 2018, vol. 44, no. 7, pp. 737–745. https://doi.org/10.14258/jcprm.2017041840].

Grishechko, L.I., Amaral-Labat, G., Szczurek, A., Fierro, V., Kuznetsov, B.N., Pizzi, A., and Celzard, A., Ind. Crops Prod., 2013, vol. 41, pp. 347–355. https://doi.org/10.1016/jindcrop.2012.04.052

Kolosov, P. V., Markin, V.I., Bazarnova, N.G., Ol’khov, Yu.A., and Generalova, E.N., Khim. Rastit. Syr’ya, 2008, no. 3, pp. 55–58.

Kolosov, P.V, Markin, V.I., Bazarnova, N.G., Yusupov, V.R., and Generalova, E.N., Khim. Rastit. Syr’ya, 2009, no. 3, pp. 39–42.

Sizmur, T., Fresno, T., Akgül, G., Frost, H., and Moreno-Jiménez, E., Bioresour. Technol., 2017, vol. 246, pp. 34–47. https://doi.org/10.1016/j.biortech.2017.07.082

Rajapaksha, A.U., Chen, S.S., Tsang, D.C., Zhang, M., Vithanage, M., Mandal, S., Gao, B., Bolan, N.S., and Ok, Y.S., Chemosphere, 2016, vol. 148, no. 27, pp. 276–291. https://doi.org/10.1016/j.chemosphere.2016.01.043

Tan, X., Liu, Y., Zeng, G., Wang, X., Hu, X., Gu, Y., and Yang, Z., Chemosphere, 2015, vol. 125, pp. 70–85. https://doi.org/10.1016/j.chemosphere.2014.12.058

Nwabanne, J. and Igbokwe, P.K., Int. J. Multidisciplinary Sci. Eng., 2012, vol. 3, no. 7, pp. 46–52.

Milenković, D.D., Milosavljević, M.M., Marinković, A.D., Dokić, V.R., Mitrović, J.Z., and Bojić, A.L., Water SA, 2013, vol. 39, no. 4, pp. 515–522. https://doi.org/10.4314/wsa.v39i4.10

Guo, Y. and Rockstraw, D.A., Carbon, 2006, vol. 44, pp. 1464–1475. https://doi.org/10.1016/j.carbon.2005.12.002

Kriaa, A., Hamdi, N., and Srasra, E., Desalination, 2010, vol. 250, no. 1, pp. 179–187. https://doi.org/10.1016/j.desal.2008.12.056

Bouhamed, F., Elouear, Z., and Bouzid, J., J. Taiwan Inst. Chem. Eng., 2012, vol. 43, pp. 741–749. https://doi.org/10.1016/j.jtice.2012.02.011

Tounsadi, H., Khalidi, A., Machrouhi, A., Farnane, M., Elmoubarki, R., Elhalil, A., Sadiq, M., and Barka, N., J. Environ. Chem. Eng., 2016, vol. 4, pp. 4549–4564. https://doi.org/10.1016/j.jece.2016.10.020

Ostroukhova, L.A., Fedorova, T.E., Onuchina, N.A., Levchuk, A.A., and Babkin, V.A., Khim. Rastit. Syr’ya, 2018, no. 4, pp. 185–195. https://doi.org/10.14258/jcprm.2018044245

Podchainova, V.N. and Simonova, L.N., Analiticheskaya khimiya elementov. Med’ (Analytical Chemistry of Elements. Copper), Moscow: Nauka, 1990, pp. 78–79.

Szczurek, A., Amaral-Labat, G., Fierro, V., Pizzi, A., and Celzard, A., Carbon, 2011, vol. 49, no. 8, pp. 2785–2794. https://doi.org/10.1016/j.carbon.2011.03.005

Wang, M., Leitch, M., and Xu, Ch.Ch., Eur. Polym. J., 2009, vol. 45, pp. 3380’3388. https://doi.org/10.1016/j.eurpolymj.2009.10.003

Gao, N., Li, A., Quan, C., Du, L., and Duan, Y., J. Anal. Appl. Pyrolysis, 2013, vol. 100, pp. 26–32. https://doi.org/10.1016/jjaap.2012.11.009

Kuznetsov, B.N., Levdanskii, V.A., Kedrova, L.K., Es’kin, A.P., Polezhaeva, N.I., Safonova, L.V., and Pavlenko, N.I., Khim. Rastit. Syr’ya, 1998, no. 3, pp. 5–12.

Goncharova, N.V., Tok, M.V., and Ryazanova, T. V., Khim. Rastit. Syr’ya, 1998, no. 2, pp. 75–78.

Mikova, N.M., Fetisova, O.Yu., Ivanov, I.P., Pavlenko, N.I., and Chesnokov, N.V., Khim. Rastit. Syr’ya, 2017, no. 4, pp. 53–64. https://doi.org/10.14258/jcprm.2017042018

Parajuli, D., Inoue, K., Ohto, K., Oshima, T., Murota, A., Funaoka, M., and Makino, K., React. Funct. Polym., 2005

Acknowledgments

The study was carried out on the equipment of the Krasnoyarsk regional collective use center, Siberian Branch, Russian Academy of Sciences.

Funding

The study was carried out under the State assignment to the Institute of Chemistry and Chemical Technology in accordance with the Program of fundamental research by State academies of sciences in the basic research avenue V.46.4.2, project no. 0356-2019-0032.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors state that they have no conflict of interest to be disclosed in the present communication.

Additional information

Russian Text © The Author(s), 2019, published in Zhurnal Prikladnoi Khimii, 2019, Vol. 92, No. 10, pp. 1333–1343.

Rights and permissions

About this article

Cite this article

Mikova, N.M., Skvortsova, G.P., Mazurova, E.V. et al. Influence Exerted by Cross-Linking Effect on Properties of Sorbents Produced from Aspen and Larch Bark. Russ J Appl Chem 92, 1422–1431 (2019). https://doi.org/10.1134/S1070427219100124

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1070427219100124