Abstract

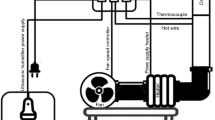

The initial premises of using a heat pump are that in winter (a cold period of a year) it is used to heat a farmhouse and in summer (a warm period), when heating the house is not required, it is used as part of a grain dryer. Analysis of the operation of a batch fluidized-bed grain dryer for maize seed grains (loading 75 kg), equipped with a heat pump for heating the drying agent, is performed. It is assumed that the source of low-potential heat in the heat pump is groundwater with a temperature of 6°C at the inlet of the heat exchanger and 8°C at the outlet, and the drying agent (air) is heated in the condenser of the heat pump up to 60°C. Freon R600a was chosen as the working body in the heat pump. It is shown that, under these conditions, the heat pump operated at the refrigeranttemperature in the evaporator of 3°C and its temperature in the condenser of 70°C makes it possible to reduce the consumption of heat for heating the drying agent by ~66% (the energy conversion coefficient is 2,98), and the use of partial recycling of the spent drying agent saves another 25% of energy. The analysis provides evidence for good perspectives of using a heat pump dryer in farms. A technique is developed for kinetic calculation of a batch fluidized-bed dryer for a granular material, taking into account the non-steady-state nature of the drying process. The technique is based on an analytical solution of the problem of mass conductivity for individual grains, makes use of the zonal method of calculation, and takes into account changes in the parameters of the drying agent during the process, both over the height of the fluidized bed and in time. The adequacy of the mathematical model for calculating the drying kinetics to the real process is demonstrated.

Similar content being viewed by others

REFERENCES

Rudobashta, S.P., Trudy Mezhdunarodnogo nauchno-tekhnicheskogo foruma “Pervye Kosyginskie chteniya” (Proc. Int. Scientific and Technical Forum “First Kosygin Readings”), Moscow: Ross. Gos. Univ. im. A.N. Kosygina, 2017, p. 33.

Rudobashta, S.P., Izv. Ross. Akad. Nauk, Ser. Energetika, 2000, no. 4, p. 98.

Rudobashta, S. and Zueva, G., Drying Technol., 2016, vol. 34, no. 5, p. 505.

Rudobashta, S.P., Zueva, G.A., and Kartashov, E.M., Theor. Found. Chem. Eng., 2016, vol. 50, no. 5, p. 718.

Bon, J. and Kudra, T., Drying Technol., 2007, vol. 25, no. 4, p. 523.

Vaquiro, H.A., Clemente, G., Garcia-Perez, J.V., Mulet, A., and Bon, J., Chem. Eng. Res. Design, 2009, no. 87, p. 885.

Rudobashta, S.P., Massoperenos v sistemakh s tverdoi fazoi (Mass Transfer in Solid Phase Systems), Moscow: Khimiya, 1980.

Rudobashta, S.P., Muravleva, E.A., and Zueva, G.A., Nauka Tsentr. Rossii, 2017, no. 6, issue 30, p. 69.

Alves-Filho, O., Heat Pump Dryers: Theory, Design and Industrial Application. New and Improved Drying Technologies, Trondheim, Norway, 2013.

Rudobashta, S.P., Teplotekhnika (Heat Engineering), Moscow: Pero, 2015.

Aerov, M.E. and Todes, O.M., Gidravlicheskiye i teplovye osnovy raboty apparatov so statsionarnym i kipyashchim zernistym sloem (Hydraulic and Thermal Fundamentals of Operation of Apparatuses with a Steady-State and Fluidized Granular Bed), Moscow: Khimiya, 1968.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

No conflict of interest was declared by the authors.

Rights and permissions

About this article

Cite this article

Rudobashta, S.P., Zueva, G.A. & Muravleva, E.A. Farm Grain Dryer with a Heat Pump and Its Calculation. Russ J Gen Chem 90, 1163–1167 (2020). https://doi.org/10.1134/S1070363220060316

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1070363220060316