Abstract

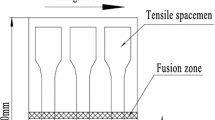

A new approach to solid-state pressure welding of Zn–22% Al aluminum–zinc alloy in vacuum at a temperature of 250°C under conditions of low-temperature superplasticity is proposed. An ultrafine equi-axial structure with an average size of both phases was obtained by annealing in an oven at 350°C followed by quenching in water. This treatment produces stable ultrafine grains of about 0.65 μm with a uniform distribution of Zn and Al grains. When welding high-height billets with pressure, barrel-like properties appear on the side surface of welded materials. It is shown that the sizing of the mold for pressure welding of cylindrical billets makes it possible to influence development of local flow and to provide the most favorable conditions of deformation by optimizing energy consumption for deformation in the zone of the welded joint. As a result of heating and precipitation, a joint superplastic deformation occurs and the main deformation is localized in the region of formation of the solid-phase joint, while most of the blanks are slightly deformed. Oxide films on the surfaces to be joined are broken by extrusion and removed by superplastic deformation in radial directions, and a new oxide-free layer appears on the surface of the workpieces to be welded. The welded area is formed due to the occurrence of metal bonds between the juvenile contacting surfaces of the welded workpieces. Mechanical tensile tests showed that the strength of the solid-phase joints was 90–95% of the ultimate strength of the base material.

Similar content being viewed by others

REFERENCES

I. F. Kolobnev, Heat Treatment of Aluminum Alloys (Metallurgiya, Moscow, 1966) [in Russian].

M. Kh. Rabinovich, Thermomechanical Treatment of Aluminum Alloys (Metallurgiya, Moscow, 1973) [in Russian].

Industrial, Deformed, Sintered and Cast Aluminum Alloys, Ed. by F. I. Kvasov and I. N. Fridlyander (Metallurgiya, Moscow, 1972) [in Russian].

T. Fukuda, Weld. Int. 26 (4), 256 (2012).

A. M. Drits and V. V. Ovchinnikov, Welding of Aluminum Alloys: Monograph (Ruda i Metally, Moscow, 2017) [in Russian].

S. K. Sundukov, R. I. Nigmetzyanov, and D. S. Fatyukhin, Russ. Metall. (Metally) 2021, 1667 (2022). https://doi.org/10.1134/S0036029521130309

H. K. Bhadeshia, Sci. Technol. Weld. J. 20 (6), 451 (2015).

D. M. Rabkin, A. V. Lozovskaya, and I. E. Sklabinskaya, Metallurgy of Aluminum Welding and Its Alloys (Naukova Dumka, Kiev, 1992) [in Russian].

R. Xiao and X. Zhang, J. Manuf. Processes 16 (2), 166 (2014).

I. J. Polmear, Light Alloys – from Traditional Alloys to Nanocrystalls (Monash Univ., Melbourne, 2006).

N. A. Belov, E. A. Naumova, and T. K. Akopyan, Mater. Sci. Technol. 33 (6), 656 (2017).

N. A. Belov, E. A. Naumova, and T. K. Akopyan, Mater. Res. 18 (6), 1384 (2015).

A. A. Bochvar, Izv. Akad. Nauk SSSR, No. 5, 649 (1948).

A. A. Bochvar and Z. A. Sviderskaya, Izv. Akad. Nauk SSSR, No. 9, 821 (1945).

T. Uesugi, Y. Takigawa, M. Kawasaki, and K. Higashi, Lett. Mater. 5 (3), 269 (2015).

R. Z. Valiev, A. P. Zhilyaev, and T. G. Langdon, Bulk Nanostructured Materials: Fundamentals and Applications (Wiley, New Jersey, 2014).

R. Z. Valiev, N. A. Krasilnikov, and N. K. Tsenev, Mater. Sci. Eng. 137, 35 (1991).

R. Z. Valiev, O. A. Kaibyshev, and R. I. Kuznetsov, Dokl. Akad. Nauk SSSR 301 (4), 864 (1988).

R. M. Imayev and V. M. Imayev, Scr. Metall. Mater. 25, 2041 (1991).

M. Kh. Mukhametrakhimov, Vestn. Mashinostr., No. 1, 51 (2021).

S. A. Saltykov, Stereometric Metallography (Stereology of Metallic Materials) (Metallurgiya, Moscow, 1976) [in Russian].

A. N. Pilyankevich, Practice of Electron Microscopy: Methods of Preparation (Mashgiz, Kiev, 1961) [in Russian].

A. V. Smirnova, G. A. Kokorin, S. M. Polonskaya, et al., Electron Microscopy: Handbook (Metallurgiya, Moscow, 1985) [in Russian].

A. A. Presnyakov, Localization of Plastic Deformation (Mashinostroenie, Moscow, 1983) [in Russian].

Funding

The work was carried out within the framework of a state program of fundamental research of the Institute for Metals Superplasticity Problems, Russian Academy of Sciences, no. 122011900474-5.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The author of this work declares that he has no conflicts of interest.

Additional information

Translated by M. Drozdova

Publisher’s Note.

Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mukhametrakhimov, M.K. Welding the Solid State of Zn–22% Al Alloy under Low-Temperature Superplasticity Conditions. Tech. Phys. 68, 139–143 (2023). https://doi.org/10.1134/S1063784223700044

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063784223700044