Abstract

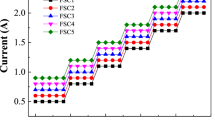

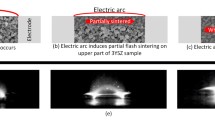

We report on the results of the analysis of the effect of flash sintering, which is observed upon heating compacted powder materials by high-intensity microwave radiation. Ceramic samples of Y2O3, MgAl2O4, and Yb: (LaO)2O3 were sintered to a density exceeding 98–99% of the theoretical value during 0.5–5 min without isothermal hold. The specific microwave power absorbed volumetrically in the samples was 20–400 W/cm3. Based on the analysis of the experimental data (microwave radiation power and heating and cooling rates) and of the microstructure of the obtained materials, we propose a mechanism of flash sintering based on the evolution of the thermal instability and softening (melting) of the grain boundaries. The proposed mechanism also explains the flash sintering effect observed when a dc or a low-frequency ac voltage is applied to the samples. The microwave heating makes it possible to implement flash sintering without using electrodes for supplying energy to the articles being sintered.

Similar content being viewed by others

References

Z. A. Munir, D. V. Quach, and M. Ohyanagi, J. Am. Ceram. Soc. 94, 1 (2011).

R. Raj, M. Cologna, and J. S. C. Francis, J. Am. Ceram. Soc. 94, 1941 (2011).

O. Guillon, J. Gonzales-Julian, B. Dargatz, T. Kessel, G. Schierning, J. Rathel, and M. Herrmann, Adv. Eng. Mater 16, 830 (2014).

M. Cologna, A. L. G. Prette, and R. Raj, J. Am. Ceram. Soc. 94, 316 (2011).

M. Yu, S. Grasso, R. McKinnon, Th. Saunders, and M. J. Reece, Adv. Appl. Ceram. 116, 24 (2017).

V. A. Fok, Tr. Leningr. Fiz.-Tekh. Inst. 5, 52 (1928).

R. Raj, J. Eur. Ceram. Soc. 32, 2293 (2012).

G. Roussy, A. Bennani, and J. M. Thiebaut, J. Appl. Phys. 62, 1167 (1987).

Y. V. Bykov, K. I. Rybakov, and V. E. Semenov, J. Phys. D: Appl. Phys. 34, R55 (2001).

V. E. Semenov and N. A. Zharova, in Advances in Microwave and Radio Frequency Processing, Ed. by M. Willert-Porada (Springer, Berlin, 2006), p. 482.

Yu. Bykov, A. Eremeev, M. Glyavin, V. Kholoptsev, A. Luchinin, I. Plotnikov, G. Denisov, A. Bogdashev, G. Kalynova, V. Semenov, and N. Zharova, IEEE Trans. Plasma Sci. 32, 67 (2004).

F. Kremer and J. R. Izatt, Int. J. Infrared Millimeter Waves 2, 675 (1981).

H. D. Kimrey and M. A. Janney, Mater. Res. Soc. Symp. Proc. 124, 367 (1988).

J. Jackson, Classical Electrodynamics (Wiley, New York, 1962).

Yu. V. Bykov, S. V. Egorov, A. G. Eremeev, V. V. Kholoptsev, K. I. Rybakov, and A. A. Sorokin, J. Am. Ceram. Soc. 96, 3518 (2015).

Yu. V. Bykov, S. V. Egorov, A. G. Eremeev, V. V. Kholoptsev, I. V. Plotnikov, K. I. Rybakov, and A. A. Sorokin, Materials 9, 684 (2016).

J.-G. Li, T. Ikegami, J.-H. Lee, and T. Mori, J. Am. Ceram. Soc. 83, 2866 (2000).

Q. Hao, W. Li, H. Zeng, Q. Yang, Ch. Dou, H. Zhou, and W. Lu, Appl. Phys. Lett. 92, 211106 (2008).

R. M. German, Sintering Theory and Practice (Wiley, New York, 1996).

S. Kochawattana, A. Stevenson, S.-H. Lee, M. Ramirez, V. Gopalan, J. Dumm, V. K. Castillo, G. J. Quarles, and G. L. Messing, J. Eur. Ceram. Soc. 28, 1527 (2008).

D. L. Johnson, J. Am. Ceram. Soc. 74, 849 (1991).

J. O. Broughton and G. M. Gilmer, J. Phys. Chem. 91, 6347 (1987).

R. Raj, J. Am. Ceram. Soc. 99, 3226 (2016).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © Yu.V. Bykov, S.V. Egorov, A.G. Eremeev, I.V. Plotnikov, K.I. Rybakov, A.A. Sorokin, V.V. Kholoptsev, 2018, published in Zhurnal Tekhnicheskoi Fiziki, 2018, Vol. 88, No. 3, pp. 402–408.

Rights and permissions

About this article

Cite this article

Bykov, Y.V., Egorov, S.V., Eremeev, A.G. et al. Flash Sintering of Oxide Ceramics under Microwave Heating. Tech. Phys. 63, 391–397 (2018). https://doi.org/10.1134/S1063784218030052

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063784218030052