Abstract

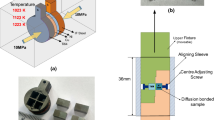

The microstructure of the transition zone and powder spacer, the concentration distribution of chemical elements over the width of the diffusion-bonded joint, and microhardness of 45 steel–compacted Ni powder spacer–45 steel layered composites formed by diffusion bonding have been investigated. It has been shown that the relative spacer thickness χ < 0.06 is optimal for obtaining a high-quality joint has been formed under a compacting pressure of 500 MPa. The solid-state diffusion bonding is accompanied by sintering the nickel powder spacer and the formation of the transition zone between the spacer and steel. The transition zone consists of solid solution of nickel in the α-Fe phase and ordered solid solution of iron in nickel (FeNi3).

Similar content being viewed by others

References

N. F. Kazakov, Diffusion Welding of Materials (Mashinostroenie, Moscow, 1976).

E. S. Karakozov, Pressure Metal Welding (Mashinostroenie, Moscow, 1986).

A. V. Lyushinskii, Diffusion Welding of Dissimilar Materials (Akademiya, Moscow, 2006).

G. V. Konyushkov and R. A. Musin, Special Techniques of Pressure Welding (I.P.R. Media, Saratov, 2009).

A. B. Bulkov, V. V. Peshkov, V. R. Petrenko, et al., Svar. Proizvod., No. 11, 18 (2011).

N. V. Boiko, I. A. Khazov, L. V. Selezneva, B. V. Bushmin, A. N. Semenov, G. V. Dubinin, S. N. Novozhilov, and M. I. Plyshevskii, Met. Sci. Heat Treat. 54, 483 (2013).

G. M. Zeer, E. G. Zelenkova, O. V. Belousov, Yu. P. Koroleva, E. N. Fedorova, and A. A. Mikheev, Tech. Phys. 60, 525 (2015).

A. V. Lyushinskii, Svarka Diagn., No. 4, 42 (2009).

A. Ustinov, Yu. Falchenko, T. Melnichenko, et al., J. Mater. Process. Technol. 213, 543 (2013).

A. I. Ustinov, Yu. V. Falchenko, T. V. Melnichenko, et al., Paton Weld. J., No. 7, 3 (2015).

A. V. Lyushinskii, E. S. Fedorova, S. V. Starovatskii, et al., Aviakosm. Priborostr., No. 6, 3 (2015).

K. A. Yushchenko, B. A. Zadery, A. V. Zvyagintseva, et al., Paton Weld. J., No. 11, 2 (2006).

J. Zhang, Q. Shen, G. Luo, et al., Mater. Des. 39, 81 (2012).

T. Enjo, K. Ikeuchi, and N. Akikawa, J. Jpn. Weld. Soc. 51, 272 (1982).

GOST 21318-75. Measurement of Microhardness by Scratch Diamond Instruments (Izd. Standartov, Moscow, 1988).

State Diagrams of Binary Metallic Systems. Handbook, Ed. by N. P. Lyakishev (Mashinostroenie, Moscow, 1996), Vol.2.

G. A. Libenson, V. Yu. Lopatin, and G. V. Komaritskii, Powder Metallurgy Processes, Vol. 2: Molding and Sintering (MISIS, Moscow, 2002).

L. Z. Mezey and J. Giber, Jpn. J. Appl. Phys. 21, 1569 (1982).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © G.M. Zeer, E.G. Zelenkova, V.I. Temnykh, A.M. Tokmin, A.A. Shubin, Yu.P. Koroleva, A.A. Mikheev, 2018, published in Zhurnal Tekhnicheskoi Fiziki, 2018, Vol. 63, No. 2, pp. 208–213.

Rights and permissions

About this article

Cite this article

Zeer, G.M., Zelenkova, E.G., Temnykh, V.I. et al. Study of Diffusion Bonding of 45 Steel through the Compacted Nickel Powder Layer. Tech. Phys. 63, 200–205 (2018). https://doi.org/10.1134/S1063784218020287

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063784218020287