Abstract

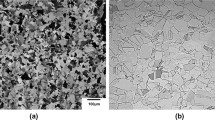

The low-temperature fracture of a high-temperature low-activated ferritic-martensitic EK-181 chromium (12%) steel (RUSFER-EK-181: Fe-12Cr-2W-V-Ta-B) is studied using impact and static concentrated bending tests as a function of the specimen dimensions (standard, small), the type of stress concentrator (V-shaped notch, fatigue crack), and the temperature (from −196 to +100°C). The ductile-brittle transition temperature falls in the range from −85 to +35°C. The temperature dependences of stress-intensity factor K Ic and fracture toughness J Ic are determined. The severest type of impact toughness tests is represented by tests of V-notched specimens with an additional fatigue crack and two lateral V-shaped notches (three-sided V-shaped notch with a central fatigue crack). The fracture energy of the steel depends on the type of stress concentrator and the specimen dimensions and is determined by the elastic energy and the plastic deformation conditions in the near-surface layers of a specimen, which are controlled by the lateral notches. At the same test temperature, the impact toughness and the fracture toughness are interrelated. Irrespective of the type of specimen (including notches and a fatigue crack), the ferritic-martensitic steel exhibits the same fracture mechanism.

Similar content being viewed by others

References

B. A. Drozdovskii and Ya. B. Fridman, Effect of Cracks on Mechanical Properties of Structural Steels (Metallurgizdat, Moscow, 1960) [in Russian].

Impact Testing of Metals: Proceedings of the 72nd Annual Meeting of the American Society for Testing and Materials, Atlantic City, N. J., 1969 (ASTM STP 466, 1970; Mir, Moscow, 1973).

W. F. Brown and J. E. Srawley, Plane Strain Crack Toughness Testing of High Strength Metallic Materials (ASTM STP 410, 1966; Mir, Moscow, 1972).

M. N. Georgiev, Viscosity of Low-Carbon Steels (Metallurgiya, Moscow, 1973) [in Russian].

Ya. B. Fridman, Mechanical Properties of Metals (Mashinostroenie, Moscow, 1974), Vol. 2 [in Russian].

R. L. Klueh and D. R. Harris, High-Chromium Ferritic and Martensitic Steels for Nuclear Application (ASTM MONO 3, 2001).

A. G. Ioltukhovskiy, M. V. Leontyeva-Smirnova, M. I. Solonin, V. M. Chernov, V. N. Gololvanov, V. K. Shamardin, T. M. Bulanova, A. V. Povstyanko, and A. E. Fedoseev, J. Nucl. Mater. 307–311, 532 (2002).

M. V. Leont’eva-Smirnova, A. N. Agafonov, G. N. Ermolaev, et al, Perspekt. Mater., No. 6, 40 (2006).

V. M. Chernov, M. V. Leontyeva-Smirnova, M. M. Potapenko, et al., Nucl. Fusion 47, 839 (2007).

G. N. Ermolaev, I. V. Golikov, M. V. Leont’eva-Smirnova, G. I. Mel’nikov, E. M. Mozhanov, and V. M. Chernov, Vopr. At. Nauki Tekh., Ser.: Materialoved. Nov. Mater., No. 2 (67), 271 (2006).

V. P. Romanovskii, Zavod. Lab., No. 2, 210 (1949).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.M. Chernov, G.N. Ermolaev, M.V. Leont’eva-Smirnova, 2010, published in Zhurnal Tekhnicheskoĭ Fiziki, 2010, Vol. 80, No. 7, pp. 72–77.

Rights and permissions

About this article

Cite this article

Chernov, V.M., Ermolaev, G.N. & Leont’eva-Smirnova, M.V. Impact toughness of EK-181 ferritic-martensitic chromium (12%) steel under loading by concentrated bending. Tech. Phys. 55, 985–990 (2010). https://doi.org/10.1134/S106378421007011X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S106378421007011X