Abstract

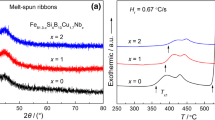

The dependence of soft magnetic properties of the Fe73.5Si13.5Nb3Cu1B9 alloy on the 2-hour air annealing temperature Tan at temperatures from 520 to 620°C is studied. It is shown that the magnetic hysteresis loop is significantly broadens and becomes more inclined, and the Curie temperature of the amorphous matrix surrounding α-FeSi nanocrystals decreases with increasing Tan. The atomic structure and phase composition of alloy samples are studied by transmission X-ray diffraction. After annealing at temperatures to 580°C, nanocrystals contain mostly D03 phase (Fe3Si stoichiometry) and are ~7 nm in average size. Their relative fraction in the alloy increases with temperature due to additional iron diffusion from the matrix to nanocrystals. After annealings at Tan > 600°C, the average nanocrystal size increases, and iron boride crystal reflections appear in X-ray diffraction patterns. Degradation of soft magnetic properties of nanocrystalline Fe73.5Si13.5Nb3Cu1B9 alloy with annealing temperature from 520 to 580°C is explained by a decrease in the silicon concentration in FeSi nanocrystals, which results in an increase in the magnetocrystalline anisotropy.

Similar content being viewed by others

REFERENCES

U. Enz, in Handbook of Magnetic Materials, Ed. by E. P. Wohlfarth (North-Holland, Amsterdam, 1982), Vol. 3, p. 1. https://doi.org/10.1016/S1574-9304(05)80087-2

Y. Yoshizawa, S. Oguma, and K. Yamauchi, J. Appl. Phys. 64, 6044 (1988). https://doi.org/10.1063/1.342149

G. Herzer, in Handbook of Magnetic Materials, Ed. by K. H. J. Buschow (Vacuum-schmelze, Hanau, 1997), Vol. 10, p. 415. https://doi.org/10.1016/S1567-2719(97)10007-5

F. Fiorillo, G. Bertotti, C. Appino, and M. Pasquale, in Wiley Encyclopedia of Electrical and Electronics Engineering (Wiley, Hoboken, 2016), p. 1. https://doi.org/10.1002/047134608x.w4504.pub2

M. Müller, H. Harada, and H. Warlimont, in Springer Handbook of Materials Data, Ed. by H. Warlimont and W. Martienssen (Springer Int., New York, 2018), p. 753. https://doi.org/10.1007/978-3-319-69743-7

F. Johnson, A. Hsaio, C. Ashe, D. Laughlin, D. Lambeth, and Mi. E. McHenry, in Proceedings of the 1st IEEE Conference on Nanotechnology IEEE-NANO 2001, Oct. 28–30, 2001, Maui, Hawaii (Inst. Electr. Electron. Eng., 2001), p. 1.

M. A. Willard and M. Daniil, in Handbook of Magnetic Materials, Ed. by K. H. J. Buschow (Elsevier, Amsterdam, 2013), Ch. 4, Vol. 21, p. 173. https://doi.org/10.1016/B978-0-444-59593-5.00004-0

G. Herzer, IEEE Trans. Magn. 26, 1397 (1990). https://doi.org/10.1109/20.104389

R. S. Turtelli, V. H. Duong, R. Grössinger, M. Schwetz, E. Ferrara, and N. Pillmayr, IEEE Trans. Magn. 36, 508 (2000). https://doi.org/10.1109/20.825825

M. LoBue, V. Basso, C. Beatrice, and P. Tiberto, IEEE Trans. Magn. 36, 3035 (2000). https://doi.org/10.1109/20.908669

S. V. Komogortsev, G. S. Krainova, N. V. Il’in, V. S. Plotnikov, L. A. Chekanova, I. V. Nemtsev, G. Yu. Yurkin, R. S. Iskhakov, and D. A. Yatmanov, Inorg. Mater. Appl. Res. 11, 177 (2020). https://doi.org/10.1134/S2075113320010219

F. Wan, A. He, J. Zhang, J. Song, A. Wang, C. Chang, and X. Wang, J. Electron. Mater. 45, 4913 (2016). https://doi.org/10.1007/s11664-016-4643-x

T. Günes, J. Non-Cryst. Solids 513, 97 (2019).https://doi.org/10.1016/j.jnoncrysol.2019.03.024

M. Xiao, Z. Zheng, L. Ji, X. Liu, Z. Qiu, and D. Zeng, J. Non-Cryst. Solids 521, 119546 (2019).

H. A. Shivaee, A. Castellero, P. Rizzi, P. Tiberto, H. R. M. Hosseini, and M. Baricco, Met. Mater. Int. 19, 643 (2013). https://doi.org/10.1007/s12540-013-4003-9

C. Smith, S. Katakam, S. Nag, Y. R. Zhang, J. Y. Law, R. V. Ramanujan, N. B. Dahotre, and R. Banerjee, Met. Mater. Trans. A 45, 2998 (2014).

S. Atalay, P. T. Squire, I. Todd, H. A. Davies, and M. R. J. Gibbs, in Proceedings of the IEEE International Magnetics Conference INTERMAG-2000, Apr. 9–13, 2000, Toronto, Ontario, Canada, 2000, Abstract BD-03. https://doi.org/10.1109/INTMAG.2000.871900

G. Manginas, G. Ababei, A. Damian, G. Stoian, M. Grigoras, M. Tibu, H. Chiriac, T. A. Ovari, and N. Lupu, in Proceedings of the IEEE International Magnetics Conference INTERMAG-2018, Apr. 23–27, 2018, Singapore, 2018, p. 1800BB12. https://doi.org/10.1109/INTMAG.2018.8508102

V. H. Duong, R. S. Turtelli, and R. Grossinger, IEEE Trans. Magn. 32, 4821 (1996). https://doi.org/10.1109/20.539163

Q. Zhu, Z. Chen, S. Zhang, Q. Li, Y. Jiang, P. Wu, and K. Zhang, J. Magn. Magn. Mater. 487, 165297 (2019).

Y. Han, R. Wei, Z. Li, F. Li, and A. Wang, J. Mater. Sci.: Mater. Electron. 28, 10555 (2017). https://doi.org/10.1007/s10854-017-6829-2

I. Todd, H. A. Davies, M. R. J. Gibbs, D. Kendall, and R. V. Major, Mater. Res. Soc. Symp. 577, 493 (1999). https://doi.org/10.1557/PROC-577-493

H. S. Todd Liu, C. H. Yin, X. X. Miao, Z. D. Han, D. H. Wang, and Y. W. Du, Mater. Sci. Technol. 24, 45 (2008).

P. Li, Z. X. Zheng, H. L. Su, and Y. C. Wu, Mater. Sci. Technol. 29, 1324 (2013). https://doi.org/10.1179/1743284713Y.0000000276

H. Q. Guo, H. Kronmüller, T. Dragon, Z. H. Cheng, and B. G. Shen, Phys. Rev. B 62, 5760 (2000). https://doi.org/10.1103/PhysRevB.62.5760

S. Kwon, S. Kim, and H. Yim, Curr. Appl. Phys. 20, 37 (2020). https://doi.org/10.1016/j.cap.2019.10.003

L. Ling, Y. Biao, G. Leding, Y. Sha, and C. Zhi-hui, in Proceedings of the 2nd IEEE International Nanoelectronics Conference INEC 2008 (2008), p. 458.

O. Geoffroy, N. Boust, H. Chazal, S. Flury, and J. Roudet, AIP Adv. 8, 047712 (2018). https://doi.org/10.1063/1.4993706

R. Shi, Z. Wang, and Y. Han, AIP Adv. 9, 055222 (2019). https://doi.org/10.1063/1.5090554

Y. Yoshizawa and K. Yamauchi, IEEE Transl. J. Magn. Jpn. 5, 1070 (1990). https://doi.org/10.1109/TJMJ.1990.4564397

S. Kwon, S. Kim, H. Yim, K. H. Kang, and C. S. Yoon, J. Alloys Compd. 826, 154136 (2020). https://doi.org/10.1016/j.jallcom.2020.154136

X. Y. Zhang, F. X. Zhang, J. W. Zhang, W. Yu, M. Zhang, J. H. Zhao, R. P. Liu, Y. F. Xu, and W. K. Wang, J. Appl. Phys. 84, 1918 (1998). https://doi.org/10.1063/1.368319

A. A. Glazer, N. M. Kleinerman, V. A. Lukshina, A. P. Potapov, and V. V. Serikov, Fiz. Met. Metalloved. 12, 56 (1991).

G. Herzer, IEEE Trans. Magn. 30, 4800 (1994). https://doi.org/10.1557/jmr.2016.324

V. V. Serikov N. M. Kleinerman, E. G. Volkova, V. A. Lukshina, A. P. Potapov, and A. V. Svalov, Phys. Met. Metallogr. 102, 268 (2006).

G. Herzer, V. Budinsky, and C. Polak, Phys. Status Solidi B 248, 2382 (2011). https://doi.org/10.1002/pssb.201147088

X. Fan, X. He, R. Nutor, R. Pan, J. Zheng, H. Ye, F. Wu, J. Jiang, and Y. Fang, J. Magn. Magn. Mater. 469, 349 (2019). https://doi.org/10.1016/j.JMMM.2018.08.078

Z. Xue, X. Li, S. Sohrabi, Y. Ren, and W. Wang, Metals 10, 122 (2020). https://doi.org/10.3390/met10010122

Y. X. Wang, G. N. Zhao, B. Yan, H. Y. Wang, W. Lu, and Y. Zhang, IEEE Trans. Appl. Supercond. 20, 1638 (2010). https://doi.org/10.1109/TASC.2010.2044236

L. K. Varga, E. Kid-Koszb, E. Zsoldos, and E. Bakos, IEEE Trans. Magn. 30, 552 (1994). https://doi.org/10.1109/20.312333

L. K. Varga, V. Franco, A. Kákay, Gy. Kovács, and F. Mazaleyrat, IEEE Trans. Magn. 37, 2229 (2001). https://doi.org/10.1109/20.951132

P. Allia, M. Baricco, P. Tiberto, and F. Vinai, J. Appl. Phys. 74, 3137 (1993). https://doi.org/10.1063/1.354581

P. Li, H. L. Su, Y. J. Song, and Y. C. Wu, Mater. Sci. Technol. 29, 460 (2013). https://doi.org/10.1179/1743284712Y.0000000160

J. Kováč, B. Kunca, and L. Novák, J. Magn. Magn. Mater. 502, 166555 (2020). https://doi.org/10.1016/j.JMMM.2020.166555

G. Herzer, in Handbook of Magnetism and Advanced Magnetic Materials (Wiley, Hoboken, 2007). https://doi.org/10.1002/9780470022184.hmm402

G. Herzer, IEEE Trans. Magn. 25, 3327 (1989). https://doi.org/10.1109/20.42292

R. Alben, J. Becker, and M. C. Chi, J. Appl. Phys. 49, 1653 (1978). https://doi.org/10.1063/1.324881

W. M. Yang, H. S. Liu, C. C. Dun, Y. C. Zhao, and L. M. Dou, Mater. Sci. Technol. 28, 1465 (2012). https://doi.org/10.1179/1743284712Y.0000000074

L. Varga and F. Mazaleyrat, in Properties and Applications of Nanocrystalline Alloys from Amorphous Precursors, Vol. 184 of NATO Science Series, Ser. II: Math., Phys. Chem., Ed. by B. Idzikowski, P. Švec, and M. Miglierini (Springer, Dordrecht, 2005), p. 157. https://doi.org/10.1007/1-4020-2965-9_14

O. Kubaschewski, Phase Diagrams of Binary Fe-based Systems (Springer, Berlin, 1982).

K. Hono, D. H. Ping, M. Ohnuma, and H. Onodera, Acta Mater. 47, 997 (1999). https://doi.org/10.1016/S1359-6454(98)00392-9

Y. Wang, Y. Zhang, A. Takeuchi, A. Makino, and Y. Kawazoe, J. Appl. Phys. 120, 145102 (2016). https://doi.org/10.1063/1.4964433

K. Hono and T. Sakurai, Appl. Surf. Sci. 87–88, 166 (1995). https://doi.org/10.1016/0169-4332(94)00513-3

R. Jha, D. R. Diercks, N. Chakraborti, A. P. Stebner, and C. V. Ciobanu, Scr. Mater. 162, 331 (2019). https://doi.org/10.1016/j.scriptamat.2018.11.039

Z. Yu, Y. Ying, W. Y. Xin, L. Wei, and Y. Biao, Sci. China Phys. Mech. Astron. 56, 1887 (2013). https://doi.org/10.1007/s11433-013-5133-2

M. Matsuura, M. Nishijima, K. Takenaka, A. Takeuchi, H. Ofuchi, and A. Makino, J. Appl. Phys. 117, 17A324 (2015).

K. Hono, Prog. Mater. Sci. 47, 621 (2002). https://doi.org/10.1016/S0079-6425(01)00007-X

N. V. Ershov, Yu. P. Chernenkov, V. I. Fedorov, V. A. Lukshina, N. M. Kleinerman, V. V. Serikov, A. P. Potapov, and N. K. Yurchenko, in Nanocrystal (InTech, Rijeka, 2011), p. 415.

O. Zivotský, Y. Jirásková, A. Hendrych, V. Matejka, L. Klimsa, and J. Bursík, IEEE Trans. Magn. 48, 1367 (2012). https://doi.org/10.1109/TMAG.2011.2171479

J. A. Moya, S. G. Caramella, and C. Berejnoib, J. Magn. Magn. Mater. 476, 248 (2019). https://doi.org/10.1016/j.JMMM.2019.01.008

B. E. Warren, X-Ray Diffraction (Addison-Wesley, New York, 1969).

B. D. Cullity and S. R. Stock, Elements of X-Ray Diffraction, 3rd ed. (Prentice-Hall, New Jersey, 2001).

V. A. Milyutin, I. V. Gervaseva, E. Beaugnon, V. S. Gaviko and E. G. Volkova, Phys. Met. Metallogr. 118, 466 (2017).

V. S. Tsepelev, Yu. N. Starodubtsev and V. Ya. Belozerov, Phys. Met. Metallogr. 119, 831 (2018).

F. Mazaleyrat and L. K. Varga, IEEE Trans. Magn. 37, 2232 (2001). https://doi.org/10.1109/20.951133

O. I. Gorbatov, A. R. Kuznetsov, Yu. N. Gornostyrev, A. V. Ruban, N. V. Ershov, V. A. Lukshina, Yu. P. Chernenkov, and V. I. Fedorov, J. Exp. Theor. Phys. 112, 848 (2011). https://doi.org/10.1134/S1063776111040066

Yu. P. Chernenkov, N. V. Ershov, V. I. Fedorov, V. A. Lukshina, and A. P. Potapov, Phys. Solid State 52, 554 (2010). https://doi.org/10.1134/S1063783410030169

G. Bertotti and F. Fiorillo, in Magnetic Alloys for Technical Applications. Soft Magnetic Alloys, Invar and Elinvar Alloys, Ed. by H. P. J. Wijn (Springer, Berlin, 1994), p. 51. https://materials.springer.com/lb/docs/sm_lbs_978-3-540-47246-9_16

Funding

This study was supported within the State contract on the subject “Magnet” no. АААА-А18-118020290129-5 and the project no. 18-10-2-5 of the Ural Branch of Russian Academy of Sciences.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by A. Kazantsev

Rights and permissions

About this article

Cite this article

Ershov, N.V., Chernenkov, Y.P., Lukshina, V.A. et al. Effect of Temperature of Long Annealing on the Structure and Magnetic Properties of Nanocrystalline FeSiNbCuB Alloy. Phys. Solid State 63, 978–991 (2021). https://doi.org/10.1134/S1063783421070076

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063783421070076