Abstract

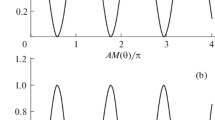

Based on the theory of diffuse martensitic transitions (DMT), the physical mechanism of the influence of dispersed precipitate nanoparticles on the appearance of such features of the deformation behavior of alloys with the shape memory effect (SME) as the stabilization of martensite at temperatures significantly higher than the As and Af temperatures characteristic of an alloy in the absence of nanoparticles c-oherent with the matrix is analyzed. The reason for the stabilization of martensite is the internal elastic stress fields associated with the particles, which serve as sites for the heterogeneous nucleation of martensite. It has been shown theoretically that, with an increase in the volume concentration of nanoparticles, the recovery of shape memory deformation occupies an increasingly narrow temperature range and occurs at an ever higher temperature. After reaching a certain critical value of the particle concentration, the return of the deformation of SM loses its stability and becomes explosive.

Similar content being viewed by others

REFERENCES

C. Picornel, J. Pons, and E. Ceresary, Acta Mater. 49, 4221 (2001).

V. Recarte, J. I. Pérez-Landazábal, P. P. Rodríguez, E. H. Bocanegra, M. L. Nó, and J. San Juan, Acta Mater. 52, 3941 (2004).

V. I. Nikolaev, P. N. Yakushev, G. A. Malygin, and S. A. Pul’nev, Tech. Phys. Lett. 36, 914 (2010).

V. I. Nikolaev, G. A. Malygin, S. A. Pulnev, P. N. Yakushev, and V. M. Egorov, Mater. Sci. Forum 738–739, 51 (2013).

V. I. Nikolaev, P. N. Yakushev, G. A. Malygin, A. I. Averkin, A. V. Chikiryaka, and S. A. Pul’nev, Tech. Phys. Lett. 40, 123 (2014).

Sh. Yang, T. Omori, C. Wang, Y. Liu, M. Nagasako, J. Ruan, R. Kainuma, and K. Liu, Sci. Rep. 6, 21754 (2016).

X. M. He, L. J. Rong, Zh. Liang, and Y. Li, J. Mater. Sci. 40, 5311 (2005).

M. Wang, M. Jiang, G. Liao, Sh. Guo, and X. Zhao, Progr. Nat. Sci. 22, 130 (2012).

C. Picornel, J. Pons, A. Paulsen, J. Frenzel, V. Kaminskii, K. Sapozhnikov, J. van Humbeeck, and S. Kustov, Scr. Mater. 180, 23 (2020).

V. I. Nikolaev, S. I. Stepanov, P. N. Yakushev, V. M. Krymov, and S. B. Kustov, Intermetallics 119, 106709 (2020).

F. Xiao, M. Jin, J. Liu, and X. Jin, Acta Mater. 96, 292 (2015).

D. Zhao, F. Xiao, F. Nie, D. Cong, W. Sun, and J. Liu, Scr. Mater. 149, 6 (2018).

P. Czaja, R. Chulist, T. Tokarsky, T. Czeppe, Y. I. Chumlyakov, and E. Cesari, J. Mater. Sci. 53, 10383 (2018).

G. A. Malygin, V. I. Nikolaev, A. I. Averin, and A. P. Zograf, Phys. Solid State 58, 2488 (2016).

G. A. Malygin, V. I. Nikolaev, I. M. Krymov, S. A. Pul’nev, and S. I. Stepanov, Tech. Phys. 64, 819 (2019).

G. A. Malygin, Phys. Solid State 45, 1566 (2003).

Sh. Yang, Y. Liu, C. Wang, and X. Liu, Acta Mater. 60, 4255 (2012).

Y. Wu, J. Wang, Ch. Jiang, and H. Xu, Intermetallics 97, 42 (2018).

A. Ibarra, D. Caillard, J. San Juan, and M. L. Nó, Appl. Phys. Lett. 90, 101907 (2007).

G. A. Malygin, Phys. Solid State 45, 345 (2003).

J. López-García, I. Unzueta, V. Sánchez-Alarcos, V. Recarte, et al., Intermetallics 94, 133 (2018).

G. A. Malygin, Phys. Solid State 61, 1251 (2019).

G. A. Malygin, Phys. Usp. 44, 173 (2001).

G. A. Malygin, Phys. Solid State 61, 149 (2019).

N. Nishida and T. Honma, Scr. Mater. 18, 1293 (1984).

V. J. Zeldovich, G. A. Sobyanina, and V. G. Pushin, Scr. Mater. 37, 79 (1997).

J. D. Eshelby, in Progress in Solid State Physics, Ed. by F. Seitz and D. Turnbull (Academic, New York, 1956), Vol. 3, p. 79.

D. Y. Li and L. Q. Chen, Acta Mater. 45, 471 (1997).

G. A. Malygin, Phys. Solid State 61, 2083 (2019).

Y. Wu, J. Wang, C. Jiang, and H. Xu, Intermetallics 97, 42 (2018).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The author declare that they have no conflicts of interests.

Additional information

Translated by V. Selikhanovich

Rights and permissions

About this article

Cite this article

Malygin, G.A. Stabilization of Martensite on Nanoprecipitates and Kinetics of Explosive Martensite Transition. Phys. Solid State 63, 94–100 (2021). https://doi.org/10.1134/S1063783421010157

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063783421010157