Abstract

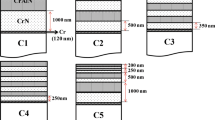

Multilayer nanostructured coatings consisting of alternating MoN and CrN layers were obtained by vacuum cathode evaporation under various conditions of deposition. The transition from micron sizes of bilayers to the nanometer scale in the coatings under investigation leads to an increase in hardness from 15 to 35.5 GPa (with a layer thickness of about 35 nm). At the same time, when the number of bilayers in the coating decreases, the average Vickers hardness increases from 1267 HV0.05 to 3307 HV0.05. An increase in the value of the potential supplied to the substrate from–20 to–150 V leads to the formation of growth textures in coating layers with the [100] axis, and to an increase in the intensity of reflections with increasing bilayer thickness. Elemental analysis carried out with the help of Rutherford backscattering, secondary ion mass spectrometry and energy dispersion spectra showed a good separation of the MoN and CrN layers near the surface of the coatings.

Similar content being viewed by others

References

Nanostructured Coatings, Ed. by A. Cavaleiro and J. T. M. de Hosson (Springer, New York, 2006).

R. L. Boxman, V. N. Zhitomirsky, I. Grimberg, L. Rapoport, S. Goldsmith, and B. Z. Weiss, Surf. Coat. Technol. 125, 257 (2000).

P. H. Mayrhofer, C. Mitterer, L. Hultman, and H. Clemens, Prog. Mater. Sci. 51, 1032 (2006).

A. D. Pogrebnyak, A. P. Shpak, N. A. Azarenkov, and V. M. Beresnev, Phys. Usp. 52, 29 (2009).

A. D. Pogrebnjak, A. G. Ponomarev, A. P. Shpak, and Yu. A. Kunitskii, Phys. Usp. 55, 270 (2012).

T. N. Koltunowicz, P. Zukowski, V. Bondariev, K. Czarnacka, O. Boiko, J. A. Fedotova, and J. V. Kasiuk, J. Alloys Compd. 650, 262 (2015).

Ya. A. Lyashenko and A. N. Zaskoka, Tech. Phys. 60, 1014 (2015).

S. N. Danilchenko, A. V. Koropov, I. Y. Protsenko, B. Sulkio-Cleff, and L. F. Sukhodub, Cryst. Res. Technol. 41, 268 (2006).

T. N. Koltunowicz, P. Zhukowski, V. Bondariev, J. A. Fedotova, and A. K. Fedotov, Acta Phys. Polon. A 123, 932 (2013).

V. M. Beresnev, O. V. Sobol’, A. D. Pogrebnjak, P. V. Turbin, and S. V. Litovchenko, Tech. Phys. 55, 871 (2010).

M. K. Samani, X. Z. Ding, N. Khosravian, B. Amin-Ahmadi, Y. Yi, G. Chen, E. C. Neyts, A. Bogaerts, and B. K. Tay, Thin Solid Films 578, 133 (2015).

Z. H. Xie, M. Hoffman, P. Munroe, R. Singh, A. Bendavid, and P. J. Martin, J. Mater. Res. 22, 2312 (2007).

J. Lackner, L. Major, and M. Kot, Bull. Polon. Acad. Sci.: Tech. Sci. 59, 343 (2011).

A. D. Pogrebnjak, S. Bratushka, V. I. Boyko, I. V. Shamanin, and Y. V. Tsvintarnaya, Nucl. Instrum. Meth. Phys. Res. B 145, 373 (1998).

A. Gilewicz and B. Warcholinski, Tribol. Int. 80, 34 (2014).

R. A. Koshy, M. E. Graham, and L. D. Marks, Surf. Coat. Technol. 202, 1123 (2007).

V. Ivashchenko, S. Veprek, A. Pogrebnjak, and B. Postolnyi, Sci. Technol. Adv. Mater. 15, 25007 (2014).

A. Komarov, F. Komarov, P. ukowski, C. Karwat, and A. Kamarou, Vacuum 63, 495 (2001).

A. D. Pogrebnyak, O. M. Ivasishin, and V. M. Beresnev, Usp. Fiz. Met. 17, 1 (2016).

A. D. Pogrebnjak, D. Eyidi, G. Abadias, O. V. Bondar, V. M. Beresnev, and O. V. Sobol, Int. J. Refract. Met. Hard Mater. 48, 222 (2015).

L. S. Metlov, M. M. Myshlyaev, A. V. Khomenko, and Ya. A. Lyashenko, Tech. Phys. Lett. 38, 972 (2012).

S. Veprek, M. G. J. Veprek-Heijman, P. Karvankova, and J. Prochazka, Thin Solid Films 476, 1 (2005).

A. D. Pogrebnjak, G. Abadias, O. V. Bondar, B. O. Postolnyi, M. O. Lisovenko, O. V. Kyrychenko, A. A. Andreev, V. M. Beresnev, D. A. Kolesnikov, and M. Opielak, Acta Phys. Polon. A 125, 1280 (2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.D. Pogrebnyak, O.V. Bondar, B. Zhollybekov, S. Konstantinov, P. Konarski, V.M. Beresnev, A.I. Kupchishin, 2017, published in Fizika Tverdogo Tela, 2017, Vol. 59, No. 9, pp. 1773–1777.

Rights and permissions

About this article

Cite this article

Pogrebnyak, A.D., Bondar, O.V., Zhollybekov, B. et al. Influence of the bilayer thickness of nanostructured multilayer MoN/CrN coating on its microstructure, hardness, and elemental composition. Phys. Solid State 59, 1798–1802 (2017). https://doi.org/10.1134/S1063783417090232

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063783417090232