Abstract

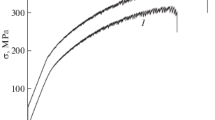

Macroscopic jumps of plastic deformation (few percent in amplitude) on creep curves of aluminum–magnesium alloy, caused by a local effect of concentrated solution of hydrochloric acid on the alloy surface, have been revealed and investigated using a complex of high-speed methods for studying the dynamics of deformation bands and discontinuous deformation. Results of computer simulation of the formation of fractal morphology of the corrosion front and elastic stress fields under stress-corrosion conditions are presented. It is shown that, in the complex structure of corrosion boundary, containing “peninsulas” and “fjords,” the level of local stress at fjord vertices exceeds the level of applied stress by ~1–1.5 orders of magnitude, which may lead to collective responce of many dislocation sources and development of macroscopic dislocation avalanche, causing a strain jump in the creep curve.

Similar content being viewed by others

REFERENCES

A. Portevin and F. Le Chatelier, C R. Acad. Sci. Paris 176, 507 (1923).

F. Savart, Ann. Chim. Fhys. 65, 337 (1837).

E. N. da C. Andrade, Proc. Roy. Soc. A 84, 1 (1910).

J. F. Bell, The Experimental Fundamentals of Solid Mechanics (Springer, Berlin, 1984).

A. A. Shibkov, M. A. Lebyodkin, T. A. Lebedkina, et al., Phys. Rev. E 102, 043003 (2020). https://doi.org/10.1103/PhysRevE.102.043003

V. V. Dubinin and G. F. Rudzei, Korroz.: Mater., Zashch., No. 12, 19 (2013).

V. B. Grigorenko, L. V. Morozova, I. P. Zhegina, and M. A. Fomina, Tr. VIAM 7 (43), 3 (2016). https://doi.org/10.18577/2307-6046-2016-0-7-1-1

R. Chlistovsky, R. Heffeman, and D. Duquesnay, Int. J. Fatigue 29 (9–11), 1941 (2007). https://doi.org/10.1016/j.ijfatigue.2007.01.010

K. Jones and D. W. Hoeppner, Corros. Sci. 48 (10), 3109 (2006). https://doi.org/10.1016/j.corsci.2005.11.008

E. N. Kablov, O. V. Startsev, I. M. Medvedev, and S. V. Panin, Korroz.: Mater., Zashch., No. 12, 6 (2013).

M. Reboul and B. Baroux, Mater. Corros. 62, 215 (2011). https://doi.org/10.1002/maco.201005650

H. Yukama, Y. Murata, M. Morinaga, et al., Acta Metall. Mater. 43, 681 (1995). https://doi.org/10.1016/0956-7151(94)00266-K

J. L. Searles, Metall. Mater. Trans. A 32, 2859 (2001). https://doi.org/10.1007/s11661-001-1036-3

G. R. Argade, N. Kumar, and R. S. Mishra, Mater. Sci. Eng. A 565, 80 (2013). https://doi.org/10.1016/j.msea.2012.11.066

S. Vargel, Corrosion of Aluminium (Elsevier, Oxford, 2004).

P. R. Swann and H. W. Pickering, Corrosion 19, 369t (1963). https://doi.org/10.5006/0010-9312-19.11.369

A. H. Cottrell, Philos. Mag. 44 (355), 829 (1953). https://doi.org/10.1080/14786440808520347

Y. Estrin and L. P. Kubin, Spatial Coupling and Propagative Plastic Instabilities, in Continuum Models for Materials with Microstructure, Ed. by H.-B. Muhlhaus (Wiley, New York, 1995), p. 395.

A. J. Yilmaz, Sci. Technol. Adv. Mater. 12, 16 (2011). https://doi.org/10.1088/1468-6996/12/6/063001

Y. Brechet and Y. Estrin, Scr. Metall. Mater. 31, 185 (1994). https://doi.org/10.1016/0956-716X(94)90172-4

Y. Brechet and Y. Estrin, Acta Metall. Mater. 43 (3), 955 (1995). https://doi.org/10.1016/0956-7151(94)00334-E

L. P. Kubin, C. Fressengeas, and G. Ananthakrishna, Dislocations in Solids, Vol. 11, Ed. by F. R. N. Nabarro and J. P. Hirth (Elsevier Science, 2001).

A. A. Shibkov, M. F. Gasanov, M. A. Zheltov, et al., Int. J. Plast. 86, 37 (2016). https://doi.org/10.1016/j.ijplas.2016.07.014

A. A. Shibkov and A. E. Zolotov, JETP Lett. 90 (5), 370 (2009).

A. A. Shibkov, M. A. Zheltov, M. F. Gasanov, et al., Crystallogr. Rep. 65 (6), 836 (2020). https://doi.org/10.1134/S1063774520060310

M. Madrigal-Canoa, J. M. Hallena, E. M. Arce-Estradaa, and Tu Line Manha, Comput. Mater. Sci. 161, 394 (2019). https://doi.org/10.1016/j.commatsci.2019.02.016

P. T. Brewick, N. Kota, A. C. Lewis, et al., Corros. Sci. 129, 54 (2017). https://doi.org/10.1016/j.corsci.2017.09.009

P. T. Brewick, V. G. DeGiorgi, A. B. Geltmacher, and S. M. Qidwai, Corros. Sci. 158, 108111 (2019). https://doi.org/10.1016/j.corsci.2019.108111

G. Edgar, Classics on Fractals (Westview, Boulder, 2004).

J. Feder, Fractals (Plenum, New York, 1988).

R. Hill, Mathematical Theory of Plasticity (Clarendon, Oxford, 1950).

P. Ch. Ivanov, L. N. Amaral, A. L. Goldberger, et al., Nature 399 (3), 461 (1999). https://doi.org/10.1038/20924

T. A. Lebedkina and M. A. Lebyodkin, Acta Mater. 56, 5567 (2008). https://doi.org/10.1016/j.actamat.2008.07.025

H. J. Jensen, Self-Organized Criticality (Cambridge University Press, Cambridge, 1998).

P. Bak, C. Tang, and K. Wiessenfeld, Phys. Rev. A 38 (1), 364 (1988). https://doi.org/10.1103/PhysRevA.38.364

Funding

The experimental part of the study, supported by the Russian Foundation for Basic Research (RFBR) (grant no. 19-08-00395), was performed on equipment of the Center of Collective Use of Derzhavin Tambov State University, with partial support of the Ministry of Science and Higher Education of the Russian Federation within the project according to agreement no. 075-15-2021-709 (unique project identifier RF—2296.61321X0037). The computer studies were supported by RFBR (grant no. 19-38-90145 “Aspiranty”).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by Yu. Sin’kov

Rights and permissions

About this article

Cite this article

Shibkov, A.A., Kochegarov, S.S., Denisov, A.A. et al. Investigation of the Mechanism of Influence of Stress Corrosion on the Development of Macroplastic Instabilities of Aluminum–Magnesium Alloy. Crystallogr. Rep. 67, 156–165 (2022). https://doi.org/10.1134/S106377452202016X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S106377452202016X