Abstract

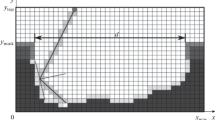

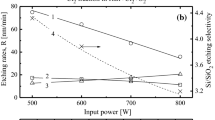

The model and the results of the modeling of etching deep grooves in Si in Сl2/Ar plasma as a function of the energy of Cl+ and Ar+ incident ions (30–250 eV), taking into consideration the redeposition of the reaction products, which are removed from the groove bottom, are represented. The groove profiles with an aspect ratio (depth-to-width groove ratio) below 5 and Si atom yield coefficients per ion as a function of the incident ion energy were in agreement with the reference data. The profile evolution of the deep grooves with an aspect ratio (AR) of up to 10 at different energies of the incident ions is shown. The influence of the redeposition coefficient of the scattered particles and the shape of the mask on the groove profile is considered. The reasons for distorting the profile of the high-aspect grooves during their etching in the Сl2/Ar plasma are discussed.

Similar content being viewed by others

References

Donnelly, V.M. and Kornblit, A., Plasma etching: yesterday, today, and tomorrow, J. Vac. Sci. Technol. A, 2013, vol. 31, no. 5, p. 050825-1.

Tinck, S., Boullar, W., and Bogaerts, A., Modeling Cl2/O2/Ar inductively coupled plasmas used for silicon etching: effects of SiO2 chamber wall coating, Plasma Sources Sci. Technol., 2011, vol. 20, no. 4, p. 045012-19.

Lane, J.M., Klemens, F.P., Bogart, K.H.A., Malyshev, M.V., and Lee, J.T.C., Feature evolution during plasma etching. polycrystalline silicon etching, J. Vac. Sci. Technol. A, 2000, vol. 18, no. 1, pp. 188–196.

Chang, S.J., Arnold, J.C., Zau, G.C., Shin, H.-S., and Sawin, H.H., Kinetic study of low energy argon ionenhanced plasma etching of polysilicon with atomic/molecular chlorine, J. Vac. Sci. Technol., 1997, vol. 15, no. 4, pp. 1853–1864.

Chang, J.P., Mahorowala, A.P., and Sawin, H.H., Plasma-surface kinetics and feature profile evolution in chlorine etching of polysilicon, J. Vac. Sci. Technol. A, 1998, vol. 16, no. 1, pp. 217–224.

Hoekstra, R.J., Grapperhaus, M.J., and Kushner, M.J., Integrated plasma equipment model for polysilicon etch profiles in an inductively coupled plasma reactor with subwafer and superwafer topography, J. Vac. Sci. Technol. A, 1997, vol. 15, no. 4, pp. 1913–1921.

Abdollahi-Alibeik, S., Zheng, J., McVittie, J.P., Saraswat, K.C., Gabriel, C.T., and Abraham, S.C., Analytical modeling of silicon etch process in high density plasma, J. Vac. Technol. B, 2001, vol. 19, no. 1, pp. 179–185.

Mahorowala, A.P. and Sawin, H.H., Etching of polysilicon in inductively coupled Cl2 and HBr discharges. II. Simulation of profile evolution using cellular representation of feature composition and Monte Carlo computation of flux and surface kinetics, J. Vac. Technol. B, 2002, vol. 20, no. 3, pp. 1064–1076.

Jin, W. and Sawin, H.H., Feature profile evolution in high-density plasma etching of silicon with Cl2, J. Vac. Sci. Technol. A, 2003, vol. 21, no. 4, pp. 911–921.

Osano, Y. and Ono, K., An atomic scale model of multilayer surface reactions and the feature profile evolution during plasma etching, Jpn. J. Appl. Phys., 2005, vol. 44, pp. 8650–8660.

Yin, Y. and Sawin, H.H., Angular etching yields of polysilicon and dielectric materials in Cl2/Ar and fluorocarbon plasmas, J. Vac. Sci. Technol. A, 2008, vol. 26, no. 13, pp. 161–173.

Guo, W. and Sawin, H.H., Modeling of the angular dependence of plasma etching, J. Vac. Sci. Technol. A, 2009, vol. 27, no. 6, pp. 1326–1336.

Wang, M. and Kushner, M.J., High energy electron fluxes in dc-augmented capacitively coupled plasmas. II. Effects on twisting in high aspect ratio etching of dielectrics, J. Appl. Phys., 2010, vol. 107, no. 2, p. 023309.

Agarwal, A. and Kushner, M.J., Plasma atomic layer etching using conventional plasma equipment, J. Vac. Sci. Technol. A, 2009, vol. 27, no. 1, pp. 37–50.

Shumilov, A.S. and Amirov, I.I., Modeling of deep grooving of silicon in the process of plasmochemical cyclic etching/passivation, Russ. Microelectron., 2007, vol. 36, no. 4, pp. 241–250.

Eckstein, W., Computer Simulation of Ion-Solid Interactions, Berlin: Springer, 1991.

Cheng, C.C., Guinn, K.V., Donnelly, V.M., and Herman, I.P., In situ laser-induced thermal desorption studies of the silicon chloride surface layer during silicon etching in high density plasmas of Cl2 and Cl2/O2 mixtures, J. Vac. Sci. Technol. A, 1994, vol. 12, p. 2630.

Guo, W., Bai, B., and Sawin, H.H., Mixing-layer kinetics model for plasma etching and the cellular realization in three-dimensional profile simulator, J. Vac. Sci. Technol. A, 2009, vol. 27, no. 2, pp. 388–403.

Belen, J.R., Gomez, S., Kiehbauch, M., Cooperberg, D., and Aydil, E.S., Feature-scale model of Si etching in SF6 plasma and comparison with experiments, J. Vac. Sci. Technol. A, 2005, vol. 23, no. 1, pp. 99–113.

Liu, X.-Y., Daw, M.S., Kress, J.D., Hanson, D.E., Arunachalam, V., Coronell, D.G., Liu, C.-L., and Voter, A.F., Ion solid surface interactions in ionized copper physical vapor deposition, Thin Solid Films, 2002, vol. 422, pp. 141–149.

Steinbruchel, C., Universal energy dependence of physical and ion-enhanced chemical etch yields at low ion energy, Appl. Phys. Lett., 1989, vol. 55, pp. 1960–1962.

Hoekstra, R.J. and Kushner, M.J., Microtrenching resulting from specular during chlorine etching of silicon, J. Vac. Technol. B, 1998, vol. 16, no. 4, pp. 2102–2104.

Coburn, J.W. and Winters, H.F., Conductance considerations in the reactive ion etching of high aspect ratio features, Appl. Phys. Lett., 1989, vol. 55, no. 26, pp. 2730–2732.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.S. Shumilov, I.I. Amirov, V.F. Lukichev, 2016, published in Mikroelektronika, 2016, Vol. 45, No. 3, pp. 177–189.

Rights and permissions

About this article

Cite this article

Shumilov, A.S., Amirov, I.I. & Lukichev, V.F. Modeling of the high aspect groove etching in Si in a Cl2/Ar mixture plasma. Russ Microelectron 45, 167–179 (2016). https://doi.org/10.1134/S1063739716030070

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063739716030070