Abstract

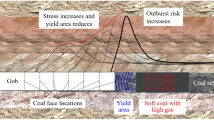

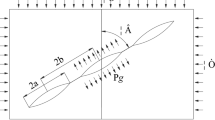

The authors discuss the mechanism of breaking coal by blasting with a view to optimizing this method of dynamic treatment of coal and improving drilling-and-basting performance. A combination model of high gassy coal is used to describe the connection between coal breaking by blasting and subsequent gas liberation. This model and the smoothed-particle hydrodynamics method are used to study evolution of damage zones and stress–strain behavior of coal in the neighborhood of a blasthole after explosion. The research findings help predict coal response to the dynamic impact.

Similar content being viewed by others

REFERENCES

Malyshev, Yu.N., Trubetskoi, K.N., and Airuni, A.T.,Fundamental’no-prikladnye metody resheniya problemy metana ugol’nykh plastov (Fundamental Applied Methods for Solving the Problem of Coalbed Methane), Moscow: AGN, 2000.

Kurlenya, M.V. and Serdyukov, S.V., Methane Desorption and Migration in Thermodynamic Inequilibrium Coal Beds, J. Min. Sci., 2010, vol. 46, no. 1, pp. 50–56.

Kurlenya, M.V. and Serdyukov, S.V., Methane Desorption and Migration in Thermodynamic Inequilibrium Coal Beds, J. Min. Sci., 2010, vol. 46, no. 1, pp. 50–56.

Guidelines for Safe Mining of Coal Seams Subject to Sudden Outbursts of Coal (Rock) and Gas. Moscow: Gosgortekhnadzor of Russia, 2000.

Mineev, S., Yanzhula, O., Hulai, O., Minieiev, O., and Zabolotnikova, V., Application of Shock Blasting Mode in Mine Roadway Construction, Min. Miner. Deposits, 2016, vol. 10 (2), pp. 91–96.

Fan, X.G., Wang, H.T., Yuan, Z.G., and Xu, H.X., The Analysis on Pre-Splitting Blasting to Improve Permeability Draining Rate in Heading Excavation, Chongqing Daxue Xuebao, J. Chongqing University, 2010, vol. 33(9), pp. 69–73.

Xie, Z., Zhang, D., Song, Z., Li, M., Liu, Ch., and Sun, D., Optimization of Drilling Layouts Based on Controlled Presplitting Blasting through Strata for Gas Drainage in Coal Roadway Strips,Energies, 2017, vol. 10 (8), pp. 1–13.

Liu, J. and Liu, Z.G., Study on Application of Deep Borehole Pre-Fracturing Blasting Technology to Seam Opening in Mine Shaft,Coal Sci. Technol., 2012, vol. 40 (2), pp. 19–24.

Liu, J., Liu, Z., and Gao, K., An Experimental Study of Deep Borehole Pre-Cracking Blasting for Gas Pre-Drainage on a Mine Heading Roadway in a Low Permeability Seam, AGH J. Min. Geo-Eng., 2012, vol. 36, no. 3, pp. 225–232.

Chang, W.B., Fan, S.W., Zhang, L., and Shu, L.Y., A Model Based on Explosive Stress Wave and Tectonic Coal Zone which Gestate Dangerous State of Coal and Gas Outburst, J. China Coal Soc., 2014, vol. 39(11), pp. 2226–2231.

Nie, B. and Li, X., Mechanism Research on Coal and Gas Outburst during Vibration Blasting, Safety Sci., 2012, vol. 50 (4), pp. 741–744.

Balashova, T.A., Study of Dynamic Load Effect on Intensification of Methane Desorption and Outburst Hazard of a Coal Seam,Candidate Tech. Sci. Thesis, Kemerovo: Kuzbass State Technical University, 1998.

Lunarzewski, L.W., Gas Emission Prediction and Recovery in Underground Coal Mines, Int. J. Coal Geol., 1993, vol. 35, pp. 117–45.

Noack, K., Control of Gas Emissions in Underground Coal Mines,Int. J. Coal Geol., 1998, vol. 35, pp. 57–82.

Lu, T.K., Yu, H., Zhou, T.Y., Mao, J.S., and Guo, B.H., Improvement of Methane Drainage in High Gassy Coal Seam Using Waterjet Technique,Int. J. Coal Geol., 2009, vol. 79, pp. 40–48.

Diamond, W.P. and Garcia, F., Prediction of Longwall Methane Emissions: An Evaluation of the Influence of Mining Practices on Gas Emissions and Methane Control Systems, Report of Investigations, National Institute for Occupational Safety and Health, Pittsburgh, 1999.

Saharan, M.R. and Mitri, H., Destress Blasting as a Mines Safety Tool: Some Fundamental Challenges for Successful Applications,Proc. Eng., 2011, vol. 36, pp. 37–47.

Konicek, P., Saharan, M.R., and Mitri, H., Destress Blasting in Coal Mining—State-of-the-Art Review, Proc. Eng., 2011, vol. 26, pp. 179–94.

Andrieux, P. and Hadjigeorgiou, J., The Destressability Index Methodology for the Assessment of the Likelihood of Success of a Large-Scale Con?ned Destress Blast in an Underground Mine Pillar,Int. J. Rock Mech. Min. Sci., 2008, vol. 45 (3), pp. 407–421.

Young, G.B.C., Computer Modeling and Simulation of Coalbed Methane Resources, Int. J. Coal Geol., 1998, vol. 35, pp. 369–379.

Odintsev, V. and Shipovskii, I., Simulating Explosive Effect on Gas-Dynamic State of Outburst-Hazardous Coal Band, J. Min. Sci., 2019, vol. 55, no. 4, pp. 556–566.

Odintsev, V. and Shipovskii, I., Numerical Simulation of the Stress-Strain State of a Coal Seam Caused by an Explosion of a Blast-Hole Charge with an Annular Gap, Proc. 26th Conference on Numerical Methods for Solving Problems in the Theory of Elasticity and Plasticity, Tomsk, 2019.

Zhu, W.C., Wei, C.H., Li S., Wei J., and Zhang, M.S., Numerical Modeling on Destress Blasting in Coal Seam for Enhancing Gas Drainage,Int. J. Rock Mech. Min. Sci., 2013, pp. 179–190.

Zhu, W.C., Liu, J., Sheng, J.C., and Elsworth, D., Analysis of Coupled Gas Flow and Deformation Process with Desorption and Klinkenberg Effects in Coal Seams, Int. J. Rock Mech. Min. Sci., 2007, vol. 44 (7), pp. 971–980.

Connell, L.D., Coupled Flow and Geomechanical Processes during Gas Production from Coal Seams, Int. J. Coal Geol., 2009, vol. 79 (1–2), pp. 18–28.

Karacan, C.O.E., Diamond, W.P., and Schatzel, S.J., Numerical Analysis of the In?uence of In-Seam Horizontal Methane Drainage Boreholes on Longwall Fact Emission Rates, Int. J. Coal Geol., 2007, vol. 72, pp.15–32.

Akhmadeev, N.Kh., Dinamicheskoe razrushenie tverdykh tel v volnakh napryazheii (Dynamic Fracture of Solid Bodies in Stress Waves), Ufa: BFAN SSSR, 1988.

Gridneva, V.A., Korneev, A.I., and Trushkov, V.G., Numerical Calculation of Stress State and Breaking of Finite-Thickness Plate on Impact by the Heads of Different Shape, Izv. AN SSSR. MTT, 1977, no. 1, pp. 146–157.

Makarov, P.V., Smolin, I.Yu., Stefanov, Yu.P., Kuznetsov, P.V., Trubitsyn, A.A., Trubitsyna, N.V., Voroshilov, S.P., and Voroshilov, Ya.S., Nelineynaya mekhanika geomaterialov i geosred(Nonlinear Mechanics of Geomaterials and Geomedia), Novosibirsk: Geo, 2007.

Sedov, L.I., Mekhanika sploshnoi sredy. Tom 1, 2(Continuous Media Mechanics. Volumes 1 and 2), Moscow: Nauka, 1976.

Wilkins, M.L., Computer Simulation of Dynamic Phenomena, Berlin, Heidelberg, New York: Springer-Verlag, 1999.

Drucker, D.C. and Prager, W., Soil Mechanics and Plastic Analysis for Limit Design, Quarterly of Applied Mathematics, 1952, vol. 10, no 2, pp. 157–165.

Nikolaevskii, V.N., Mekhanika poristykh i treshchinovatykh sred (Mechanics of Porous and Fractured Bodies), Moscow: Nedra, 1984.

Stefanov, Yu.P., Localization of Deformation and Fracture in Geomaterials. Numerical Simulation, Fiz. Mezomekh., 2002, vol. 5. no. 5, pp. 107–118.

Stefanov, Yu.P., Bakeev, R.A., El’tsov, I.N., and Akhtyamova, A.I., Numerical Study of Dilatancy Zone Formation and Compaction around Boreholes, Izv. Vuzov, Fizika, 2013, vol. 56, no. 7/3, pp. 101–104.

Shipovskii. I.E., Simulation for Fracture by Smooth Particle Hydrodynamics Code, Scientific Bulletin of National Min. University, 2015, Iss. 1 (145), pp. 76–82.

Zakharov, V.N., Trofimov, V.A. Shipovskii, I.E, and Malinnikova, O.N., Modeling the Influence of Pulp Masses in Dump Massive on the Dynamics of Landslide Zones Development, Izv. TulGU, Earth Sciences, 2020, vol. 1, pp. 359–375.

Trofimov, V.A, Shipovskii, I.E., Malinnikova, O.N, and Xu, W.J., Numerical Approach to Computer Simulation of Landslide Events,Proc. of the International Conference on Advanced Materials with Hierarchical Structure for New Technologies and Reliable Structures, Tomsk, 2019.

Malinnikova, O.N., Trofimov, V.A, and Shipovskii, I.E., Method of Smoothed Particles in Modeling Failure and Roof Caving, GIAB, Special Issue 49, 2018, vol. 2, no. 11, pp. 464–475.

Efremovtsev, N.N., Trofimov, V.A, and Shipovskii, I.E., Strain Localization in a Wave Field Induced by Elongated Charge Explosion,GIAB, 2020, no. 6, pp. 73–85.

Trofimov, V.A. and Shipovskii, I.E., Simulation Fragmentation of Samples of Rock at Explosive Loading, Proc. 8th Int. Sci. Conference on the Problems of Complex Development of Georesources, Khabarovsk, 2020.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fiziko-Tekhnicheskie Problemy Razrabotki Poleznykh Iskopaemykh, 2020, No. 5, pp. 69–81. https://doi.org/10.15372/FTPRPI20200509.

Rights and permissions

About this article

Cite this article

Trofimov, V.A., Shipovskii, I.E. COMPUTER MODELING OF COAL SEAM BLASTING. J Min Sci 56, 741–752 (2020). https://doi.org/10.1134/S106273912005707X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S106273912005707X