Abstract

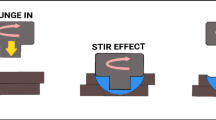

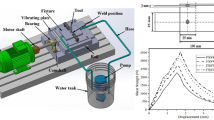

Friction stir welding has found wide application in aircraft and rocket engineering, primarily due to the possibility of obtaining welded joints with a strength close to the strength of the base material. One of the most promising methods of such welding is spot friction stir welding that can serve as an alternative to electric contact spot welding and rivet joints. For the introduction of spot friction stir welding into the production of critical products, it is necessary to consider issues related to nondestructive quality control of welded joints obtained by this welding method. The purpose of this work is to substantiate the applicability of the ultrasonic echo method to quality control of welded joints obtained by spot friction stir welding. The relevance of the work is confirmed by the fact that to date there is no sufficiently complete information about the results of experimental studies aimed at analyzing the characteristics of welded joints obtained by spot friction stir welding. The authors of the article propose to use the ultrasonic echo method. The testing was carried out using an ultrasonic flaw detector with a dual-element piezoelectric transducer on samples prepared using spot friction stir welding. As a result of ultrasonic testing, defects such as lack of penetration and sloting were found in three samples; this was confirmed by metallographic studies. Samples with no defects were subjected to mechanical tests, as a result of which it was found that the strength of the resulting welded joints is comparable to the strength of the base metal in the samples. Metallographic studies carried out on the samples after mechanical tests also confirmed the lack of defects in the welded joints. Thus, we show the relationship between the results of ultrasonic testing, metallographic studies, and mechanical tests, which allows us to substantiate the applicability of the ultrasonic echo method to quality control of welded joints obtained by spot friction stir welding.

Similar content being viewed by others

REFERENCES

GOST (State Standard) ISO 25239-1-2020. Friction welding with mixing. Aluminum. Part 1. Vocabularly, 2020.

GOST (State Standard) ISO 25239-2-2020. Friction welding with mixing. Aluminum. Part 2. Construction of welded joints, 2020.

GOST (State Standard) ISO 25239-3-2020. Friction welding with mixing. Aluminum. Part 3. Certification of welders–operators, 2020.

GOST (State Standard) ISO 25239-4-2020. Friction welding with mixing. Aluminum. Part 4. Technical requirements and certification of welding procedures, 2020.

GOST (State Standard) ISO 25239-5-2020. Friction welding with mixing. Aluminum. Part 5. Quality and control requirements, 2020.

Borovkov, A.I., Bychenok, V.A., Prokhorovich, V.E., Fedorov, A.V., Oxenyuk, A.S., Mayorov, A.L., Berkutov, I.V., and Alifirenko, E.A., The role of friction welding with mixing in the production of products of the rocket and space industry, Svarka Diagn., 2022, no. 3, pp. 36–42.

Sergeeva, E.V., Friction welding with mixing in the aerospace industry (review), Avtom. Svarka, no. 5, 2013, pp. 58–62.

Varochko, A.G., Kuznetsov, S.V., Prokhorovich, V.E., Polovtsev, V.A., Bychenok, V.A., and Saratov, N.N., History of formation and prospects of development of friction mixing welding technology in JSC “M.V. GKNPC Khrunicheva,” Tekhnologiya Mashinostroeniya, Svarochnoye Proizvodstvo i Rodstvennye Protsessy, 2021, no. 4, pp. 16–41.

Albannai Abdulaziz, I., Review of the common defects in friction stir welding, Int. J. Sci. Technol. Res., 2020, no. 9, pp. 318–329.

Zhang, H., Luo, S., and Xu, W., Influence of welding speed on zigzag line feature and tensile property of a friction-stir-welded Al–Zn–Mg aluminum alloy, J. Mater. Eng. Perform., 2019, no. 28, pp. 1790–1800.

Soni Neetesh, Chandrashekhar Sangam, Kumar, A., and Chary, V.R., Defects formation during friction stir welding: a review, Int. J. Eng. Manage. Res., 2016, no. 10, pp. 121–125.

Kah Paul, Rajan Richard, Martikainen Jukka, and Suoranta Raimo, Investigation of weld defects in friction stir welding and fusion welding of aluminium alloys, Int. J. Mech. Mater. Eng., 2015, no. 12, pp. 1–10.

Polovtsev, V.A., Makarov, N.V., Shillo, G.V., Sabantsev, A.N., Smirnova, T.N., and Strikman, M.M., Friction welding of aluminum liners of high-pressure metal composite cylinders, Svar. Proizvod., 2007, no. 12, pp. 25–27.

El-Sayed Mostafa, M., Shash, A.Y., Abd-Rabou, M., and El Sherbiny Mahmoud, G., Welding and processing of metallic materials by using friction stir technique: A review, J. Adv. Joining Proces., 2021, vol. 3, p. 100059.

Industry Standard OST 134-1051-2010. Friction welding. Technical requirements for welded joints, 2010.

Al-Moussawi, M. and Smith, A.J., Defects in friction stir welding of steel, Metallogr. Microstruct. Anal., 2018, no. 7, pp. 194–202.

Kumar Ratnesh, Chattopadhyaya Somnath, Hloch Sergej, Krolczyk Grzegorz, and Legutko Stanislaw, Wear characteristics and defects analysis of friction stir welded joint of aluminium alloy 6061-T6, Eksploatacja I Niezawodnosc, 2016, no. 18, pp. 128–135.

Khan Noor Zaman, Khan Zahid, A., Siddiquee Arshad Noor, AL-Ahmar Abdulrahman, M., and Abidi Mustufa, H., Analysis of defects in clean fabrication process of friction stir welding, Trans. Nonferrous Met. Soc. China, 2017, vol. 27, no. 7, pp. 1507–1516.

Eliseev, A.A., Regularities of structural-phase transformations in heat-strengthened aluminum alloys during friction welding with mixing with ultrasonic action, Cand. Sci. (Eng.) Dissertation, Tomsk, 2018.

Sewell Neil, Wright Julian, and Wright Jonathan, Detection of kissing bonds in friction stir welds, 11th Int. Symp. Friction Stir Weld. (Cambridge, 2016).

Santos Mário and Santos Jaime, Lamb waves technique applied to the characterization of defects in friction stir welding of aluminum plates: comparison with X-ray and ultrasonic C-scan, J. Test. Eval., 2010, vol. 38, no. 5, pp. 1–7.

Stepanova, K.A., Kinzhagulov, I.Yu., Yakovlev, Yu.O., Kovalevich, A.S., Ashikhin, D.S., and Alifanova, I.E., Applying laser-ultrasonic and acoustic-emission methods to nondestructive testing at different stages of deformation formation in friction stir welding, Russ. J. Nondestr. Test., 2020, vol. 56, no. 3, pp. 191–200.

Lévesque, D., Dubourg, L., and Blouin, A., Laser ultrasonics for defect detection and residual stress measurement of friction stir welds, Nondestr. Test. Eval., 2011, vol. 26, nos. 3–4, pp. 319–333.

NDT Control. The method of ultrasonic inspection of welded joints obtained by friction welding with mixing, using phased array technology. https://ndt-control.ru/2018/05/06/metodika-ultrazvukovogo-kontrolya-svarnyxsoedinenij-poluchennyx-svarkoj-treniem-s-peremeshivaniem-s-ispolzovaniem-texnologii-fazirovannojantennoj-reshetki. Cited December 21, 2021.

Hand-held ultrasonic spot welding control devices. http://activetest.ru/spotweld_systems/. Cited January 17, 2023.

Platform Tessonics. https://www.tessonics.com/products/f1. Cited January 17, 2023.

Olympus. Spot welding. https://www.olympus-ims.com/ru/spot-weld-testing. Cited January 17, 2022.

GOST (State Standard) 14797-85. Rivets with a semicircular head (increased accuracy). Design and dimensions, 1986.

GOST (State Standard) 14803-85. Rivets (high precision). General technical conditions, 1986.

Funding

The study was conducted by Peter the Great St. Petersburg Polytechnic University with the support of the strategic academic leadership program “Priority 2030” of the Russian Federation, agreement no. 075-15-2021-1333 of September 30, 2021.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Borovkov, A.I., Prokhorovich, V.E., Bychenok, V.A. et al. Ultrasonic Inspection Technique for Welded Joints Obtained by Spot Friction Stir Welding. Russ J Nondestruct Test 59, 149–160 (2023). https://doi.org/10.1134/S1061830923700262

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061830923700262