Abstract

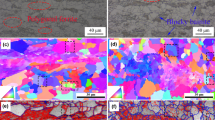

Signal processing is essential to extract precise and transparent information about the characterization of the ferromagnetic materials produced during the magnetic Barkhausen noise (MBN) analysis. In the present research work, MBN signal obtained from two steels, i.e., IS-2062 steel and AISI D2 tool steel, is analyzed using MATLAB, where the shape and characteristics of the MBN signal distinguish materials properties of these two steels. The variation in Barkhausen noise signal profile is assessed, and a correlation between the material’s properties and the signal’s characteristics is obtained at various magnetizing frequency (MF). The raw MBN and average RMS profile change insignificantly within the IS 2062 steel. But, compared to the AISI D2 tool steel, there is a sudden drop in the peak and RMS profile within a wide range of the MF at constant magnetizing field intensity (MFI). BN signal’s characteristics correlated well with grain size and hardness for both steel and clearly, indicated that AISI D2 tool steel has a smaller grain size. Interestingly at low magnetic field intensity 200 Oe, no magnetic response was observed in AISI D2 steel, indicating the high hardness and more grain boundaries of this steel which hindered the magnetic domain wall activities at low magnetic field. But at higher magnetic field (500 Oe), magnetic response was obtained from AISI D2 tool steel, indicating the requirement of minimum magnetic field for domain wall motion. It is also demonstrated that the variation in MFI from 200 to 500 Oe and MF influences the shape of the hysteresis loop and its characteristics such as permeability, coercivity, and remanence.

Similar content being viewed by others

REFERENCES

Brown, M., Wright, D., M’Saoubi, R., McGourlay, J., Wallis, M., Mantle, A., Crawforth, P., and Ghadbeigi, H., Destructive and non-destructive testing methods for characterization and detection of machining-induced white layer: A review paper, CIRP J. Manuf. Sci. Technol., 2018, vol. 23, pp. 39–53.

Neslušan, M., Čížek, J., Kolařík, K., Minárik, P., Čilliková, M., and Melikhova, O., Monitoring of grinding burn via Barkhausen noise emission in case-hardened steel in large-bearing production, J. Mater. Process. Technol., 2017, vol. 240, pp. 104–117.

Karpuschewski, B., Bleicher, O., and Beutner, M., Surface integrity inspection on gears using Barkhausen noise analysis, Procedia Eng., 2011, vol. 19, pp. 162–171.

Ortega-Labra, O., Le Manh, T., Martinez-Ortiz, P., Hallen, J.M., and Perez-Benitez, J.A., A novel system for non-destructive evaluation of surface stress in pipelines using rotational continuous magnetic Barkhausen noise, Meas. J. Int. Meas. Confed., 2019, vol. 136, pp. 761–774.

Neslušan, M., Minárik, P., Grenčík, J., Trojan, K., and Zgútová, K., Non-destructive evaluation of the railway wheel surface damage after long-term operation via Barkhausen noise technique, Wear, 2019, vol. 420–421, pp. 195–206.

Yang, Y., Fan, M., Cao, B., Cai, E., and Wang, P., Reliable characterization of bearing rings using eddy current and Barkhausen noise data fusion, J. Magn. Magn. Mater., 2019, vol. 489, p. 165349.

Gupta, S.K., Raja, A.R., Vashista, M., and Yusufzai, M.Z.K., Effect of gas metal arc welding on magnetic response of ferritic stainless steel, Arab. J. Sci. Eng., 2020, vol. 45, pp. 1293–1303.

Rößler, M., Putz, M., Hochmuth, C., and Gentzen, J., In-process evaluation of the grinding process using a new Barkhausen noise method, Proc. CIRP 99 (2021), pp. 202–207.

Sackmann, D., Heinzel, J., and Karpuschewski, B., An approach for a reliable detection of grinding burn using the Barkhausen noise multi-parameter analysis, Proc. CIRP 87 (2020), pp. 415–419.

Srivastava, A., Kumar, H., Yusufzai, M.Z.K., and Vashista, M., Barkhausen noise signal analysis of heat treated samples at various magnetising frequencies, Int. J. Mater. Prod. Technol., 2018, vol. 57, pp. 287–298.

Astudillo, M.R.N., Nicolás, M.N., Ruzzante, J., Gómez, M.P., Ferrari, G. C., Padovese, L.R., and Pumarega, M.I.L., Correlation between martensitic phase transformation and magnetic barkhausen noise of AISI 304 Steel, Proc. Mater. Sci., 2015, vol. 9, pp. 435–443.

Jarrahi, F., Kashefi, M., and Ahmadzade-Beiraki, E., An investigation into the applicability of Barkhausen noise technique in evaluation of machining properties of high carbon steel parts with different degrees of spheroidization, J. Magn. Magn. Mater., 2015, vol. 385, pp. 107–111.

Moses, A.J., Patel, H.V., and Williams, P.I., AC Barkhausen noise in electrical steels: Influence of sensing technique on interpretation of measurements, J. Electr. Eng., 2006, vol. 57, pp. 3–8.

Qiu, F., Ren, W., Tian, G.Y., and Gao, B., Characterization of applied tensile stress using domain wall dynamic behavior of grain-oriented electrical steel, J. Magn. Magn. Mater., 2017, vol. 432, pp. 250–259.

Raja, A.R., Vashista, M., and Khan Yusufzai, M.Z., Estimation of material properties using hysteresis loop analysis in friction stir welded steel plate, J. Alloys Compd., 2020, vol. 814, p. 152265.

Srivastava, A., Awale, A., Vashista, M., and Yusufzai, M.Z.K., Characterization of ground steel using nondestructive magnetic barkhausen noise technique, J. Mater. Eng. Perform., 2020, vol. 29, pp. 4617–4625.

Sharma, A., Chaudhari, A., Awale, A.S., Yusufzai, M.Z.K., and Vashista, M., Effect of grinding environments on magnetic response of AISI D2 tool steel, Russ. J. Nondestr. Test., 2021, vol. 57, pp. 212–221.

Shrivastava, A.K., Sharma, A., Awale, A.S., Yusufzai, M.Z.K., and Vashista, M., Assessment of grinding burn of AISI D2 tool steel using Barkhausen noise technique, J. Inst. Eng. Ser. C, 2021, vol. 102, pp. 885–896.

Anglada-Rivera, J., Padovese, L.R., and Capó-Sánchez, J., Magnetic Barkhausen noise and hysteresis loop in commercial carbon steel: Influence of applied tensile stress and grain size, J. Magn. Magn. Mater., 2001, vol. 231, pp. 299–306.

Padovese, L.R., Martin, N., and Millioz, F., Time-frequency and time-scale analysis of Barkhausen noise signals, Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng., 2009, vol. 223, pp. 577–588.

Vashista, M. and Paul, S., Novel processing of barkhausen noise signal for assessment of residual stress in surface ground components exhibiting poor magnetic response, J. Magn. Magn. Mater., 2011, vol. 323, pp. 2579–2584.

Luo, X., Wang, Y., Zhu, B., Zhang, Y., and Zhang, Y., Super-resolution spectral analysis and signal reconstruction of magnetic Barkhausen noise, NDT & E Int., 2015, vol. 70, pp. 16–21.

Roskosz, M., Krzysztof, F., and Schabowicz, K., Evaluation of ferromagnetic steel hardness based on an analysis of the Barkhausen noise number of events, Materials (Basel), 2020, vol. 13, p. 2059.

Unterberg, M., Stanke, J., Trauth, D., and Bergs, T., A time series classification approach to non-destructive hardness testing using magnetic Barkhausen noise emission, Prod. Eng., 2021, vol. 15, pp. 509–517.

Chaudhari, A., Sharma, A., Awale, A.S., Yusufzai, M.Z.K., and Vashista, M., Effect of ultrasonic vibration assisted dry grinding on hysteresis loop characteristics of AISI D2 tool steel, Sadhana—Acad. Proc. Eng. Sci., 2021, vol. 46.

Bi, G., Guan, Y., Chen, X., Tan, W., Huang, W., Gao, Y., and Wang, M., Evaluation of uncertainty in determining average grain size by ASTM E112 standard, IOP Conf. Ser. Mater. Sci. Eng., 2020, vol. 733.

Vashista, M. and Yusufzai, M.Z.K., Effect of magnetizing field strength and magnetizing frequency on hysteresis loop shape and its characteristics, IOP Conf. Ser. Mater. Sci. Eng., 2018, vol. 346.

Funding

This research was financially supported by IIT BHU under grant (letter no. IIT (BHU)/Dec/2013-14/5110/L) and Institute Research Project ((IIT (BHU)/R & D)/IRP/2015-16/2832).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Diwakar, V., Sharma, A., Yusufzai, M.Z. et al. Barkhausen Noise Signal Analysis of IS 2062 Steel and AISI D2 Tool Steel with Different Range of Magnetizing Frequency and Intensity. Russ J Nondestruct Test 58, 821–832 (2022). https://doi.org/10.1134/S1061830922090054

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061830922090054