Abstract

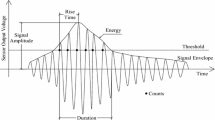

Fiber-reinforced cement-based materials have received extensive attention in the field of structural strengthening. Using ground ceramic powder to replace part of cement, and using crushed ceramics to completely replace quartz sand, an environmentally friendly cement-based material was prepared. A new type of engineered cementitious composite (Cera-ECC) was obtained by adding an appropriate amount of polyvinyl alcohol (PVA) fiber. Electric accelerated corrosion was introduced to study the corrosion of steel bars in Cera-ECC and the damage process of the surrounding engineered cementitious composite (ECC) using acoustic emission technology. It is found that the introduction of ceramic powder in an appropriate amount can form a stable passive film on the surface of the steel bar. The cumulative acoustic emission hits over time shows that the damage process can be divided into five stages—before depassivation, rupture of the passive film, accumulation of corrosion products, internal expansion and cracking, and formation of macroscopic cracks. Signals at different stages of damage have different spectral characteristics. As the damage continues to increase, the peak frequency of the acoustic emission signal gradually changes from low to high. With the increase of fiber content, the appearance time of macro cracks is effectively prolonged.

Similar content being viewed by others

REFERENCES

Li, J.Q. et al., Durability of ultra-high performance concrete—a review, Constr. Build. Mater., 2020, vol. 255, p. 119296.

Qu, F.L. et al., Durability deterioration of concrete under marine environment from material to structure: A critical review, J. Build. Eng., 2021, vol. 35, p. 102074.

Zheng, A.H. et al., Experimental investigation of corrosion-damaged RC beams strengthened in flexure with FRP grid-reinforced ECC matrix composites, Eng. Struct., 2021, vol. 244, p. 112779.

Naqi, A. and Jang, J.G., Recent progress in green cement technology utilizing low-carbon emission fuels and raw materials: A review, Sustainability, 2019, vol. 11, no. 2, p. 537.

Ray, S. et al., Use of ceramic wastes as aggregates in concrete production: A review, J. Build. Eng., 2021, vol. 43, p. 102567.

Al Arab, A., Hamad, B., and Assaad, J.J., Strength and durability of concrete containing ceramic waste powder and blast furnace slag, J. Mater. Civ. Eng., 2022, vol. 34, no. 1, p. 04021392.

Pavesi, T.B., Rohden, A.B., and Garcez, M.N.R., Supporting circular economy through the use of red ceramic waste as supplementary cementitious material in structural concrete, J. Mater. Cycles Waste Manage., 2021, vol. 23, no. 6, pp. 2278–2296.

Xu, K.C. et al., Mechanical properties of low-carbon ultrahigh-performance concrete with ceramic tile waste powder, Constr. Build. Mater., 2021, vol. 287, p. 123036.

Katzer, J., et al., Influence of varied waste ceramic fillers on the resistance of concrete to freeze-thaw cycles, Materials, 2021, vol. 14, no. 3, p. 624.

Hilal, N.N., Mohammed, A.S., and Ali, T.K.M., Properties of Eco-friendly concrete contained limestone and ceramic tiles waste exposed to high temperature, Arabian J. Sci. Eng., 2020, vol. 45, no. 5, pp. 4387–4404.

Ogawa, Y. et al., Effects of porous ceramic roof tile waste aggregate on strength developmentand carbonation resistance of steam-cured fly ash concrete, Constr. Build. Mater., 2020, vol. 236, p. 117462.

Siddique, S., Shrivastava, S., and Chaudhary, S., Influence of ceramic waste as fine aggregatein concrete: Pozzolanic, XRD, FT-IR, and NMR investigations, J. Mater. Civ. Eng., 2018, vol. 30, no. 9, p. 04018227.

Zou, Z.H. et al., Relationship between half-cell potential and corrosion level of rebar in concrete, Corros. Eng. Sci. Technol., 2016, vol. 51, no. 8, pp. 588–595.

Da, B. et al., Reinforcement corrosion research based on the linear polarization resistancemethod for coral aggregate seawater concrete in a marine environment, Anti-Corros. Methods Mater., 2018, vol. 65, no. 5, pp. 458–470.

Hu, J.Y. et al., Electrochemical noise analysis of cathodically protected steel reinforcement inconcrete using carbon fiber sheet as anode, Constr. Build. Mater., 2021, vol. 133, p. 125474.

Li, W.J. et al., Monitoring concrete deterioration due to reinforcement corrosion by integrating acoustic emission and FBG strain measurements, Sensors, 2017, vol. 17, no. 3, p. 657.

Li, Z. et al., Combined application of novel electromagnetic sensors and acoustic emissionapparatus to monitor corrosion process of reinforced bars in concrete, Constr. Build. Mater., 2020, vol. 245, p. 118472.

Hoshi, Y. et al., Non-contact measurement to detect steel rebar corrosion in reinforced concrete by electrochemical impedance spectroscopy, J. Electrochem. Soc., 2019, vol. 166, no. 11, pp. C3316–C3319.

Qiu, Q.W., Zhu, J.H., and Dai, J.G., In-situ X-ray microcomputed tomography monitoring ofsteel corrosion in engineered cementitious composite (ECC), Constr. Build. Mater., 2020, vol. 262, p. 120844.

Abouhussien, A.A. and Hassan, A.A.A., Acoustic emission monitoring of corrosion damage propagation in large-scale reinforced concrete beams, J. Perform. Constr. Facil., 2018, vol. 32, no. 2, p. 04017133.

Goldaran, R. and Turer, A., Application of acoustic emission for damage classification and assessment of corrosion in pre-stressed concrete pipes, Measurement, 2020, vol. 160, p. 107855.

Jirarungsatian, C. and Prateepasen, A., Pitting and uniform corrosion source recognition using acoustic emission parameters, Corros. Sci., 2010, vol. 52, no. 1, pp. 187–197.

Farnam, Y. et al., Acoustic emission waveform characterization of crack origin and mode in fractured and ASR damaged concrete, Cem. Concr. Compos., 2015, vol. 60, pp. 135–145.

Haselbach, B.L., Acoustic emission of debonding between fibre and matrix to evaluate local adhesion, Compos. Sci. Technol., 2003, vol. 63, no. 15, pp. 2155–2162.

Hamam, Z. et al., Acoustic emission signal due to fiber break and fiber matrix debondingin model composite: A computational study, Appl. Sci., 2021, vol. 11, no. 18, p. 8406.

ACKNOWLEDGMENTS

The authors gratefully acknowledge the financial support for this study from the Opening Funds of State Key Laboratory of Building Safety (BSBE2019-07) and Natural Science Foundation of Hebei Province (E2021210088).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Lipeng, W., Zhengzheng, L. & Changhong, L. Corrosion Induced Damage Monitoring of Engineered Cementitious Composite Containing Ceramic Wastes by Acoustic Emission. Russ J Nondestruct Test 58, 259–267 (2022). https://doi.org/10.1134/S1061830922040118

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061830922040118