Abstract

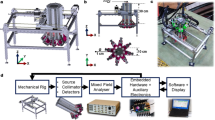

The piping systems used for the transportation of liquids and gases in power stations, petroleum petrochemical facilities, and chemical plants are significantly impacted by corrosive processes. One of the most destructive forms of corrosion is pitting corrosion, which produces holes on piping metal surfaces. Monitoring pit depth is necessary in order to prevent leakage in the piping system, especially during operation. However, measuring pit depth as a part of periodical inspections is complicated since the pit depth on the outside wall of a pipe may vary. Non-destructive testing (NDT) methods such as ultrasonic, liquid penetrants, and magnetic particles are used to detect defects in industrial components; however, they first require the removal of insulation and the shutdown of the pipe system. Another alternative NDT technique, tangential radiography technique (TRT), offers a solution to this problem as tests can be conducted without removing piping insulation, allowing testing while the piping system is online. In this study, we tested TRT using an X-ray radiation source, which has good controllability (i.e., intensity and exposure time) and a lower impact on the human body than do γ-ray sources. We focused on the comparison of film density measurements using a density meter and a light meter. The magnification of pit diameter was used to obtain an equation for small-diameter pipes (i.e., diameter of less than 50 mm). The working voltage was varied (200, 230, and 260 kV) in order to generate appropriate X-ray energies to measure various pit depth (20, 40, and 60%, receptively) of a stepped steel pipe specimen. Film density measurements using the density and light meters showed similar results; however, the film density result using the density meter was more accurate. All tangential side edges of the specimen burned off for film densities above 3.5. Degrees of magnification (1.0123, 1.0254, and 1.0379) varied as a function of distance from the midpoint of the X-ray target (30, 60, or 90 mm, respectively). Using the results, a linear equation with three variables was obtained to determine the actual diameter of pitting: 0.000385436a + 0.038350128b + 0.000467083c = d; where the actual diameter = film diameter/d. High working voltage produced low film contrast, high film definition, and low scatter. Low working voltage produced high film contrast, low film definition, and high scatter. Based on our results, a working voltage of 260 kV is most appropriate for effective analysis.

Similar content being viewed by others

REFERENCES

Harara, W., Pit-depth measurement on large diameter pipes by tangential radiography using a Co-60 gamma-ray source, Russ. J. Nondestr. Test., 2004, vol. 40, no. 11, pp. 782–788.

Edalati, K., Rastkhah, N., Kermani, A., Seiedi, M., and Movafeghi, A., The use of radiography for thickness measurement and corrosion monitoring in pipes, Int. J. Pressure Piping, 2006, no. 83, pp. 736–741.

Balasko, M., Svab, E., Kuba, A., Kiss, Z., Rodek, L., and Nagy, A., Pipe corrosion and deposit study using neutron- and gamma- radiation sources, Nucl. Instrum. Methods Phys. Res., Sect. A, 2005, no. 542, pp. 302–308.

Boateng, A., Danso, K.A., and Dagadu, C.P.K., Non-destructive evaluation of corrosion on insulated pipe using tangential radiographic technique, Int. J. Sci. Technol. Res., 2013, vol. 2, no. 6, pp. 7–13.

Zirnhelt, J., Einav, I., and Infanzon, S., Radiographic evaluation of corrosion and deposits: An IAEA co-ordinated research project, inProc. 3rd Pan Am. Conf. Nondestr. Test. (PANNDT), Rio de Janeiro, Brazil: Assoc. Bras. Ensaios Nao Destrutivos (ABENDI), 2003.

Zscherpel, U., Ewert, U., Infanzon, S., Rastkhan, N., Vaidya, P.R., and Ekinci, S., Radiographic evaluation of corrosion and deposits in pipelines: Results of an IAEA coordinated research programme, in Proc. 9th Eur. Conf. Nondestr. Test. (ECNDT), Berlin, Germany: Deutsche Gesellschaft fur Zerstörungsfreie Prufung e.V. (DGfZP), 2006, vol. 11, no. 11, pp. 1–14.

Hamzah, A.R., Amir, S.M.M., Sayuti, S., and Rejab, S., Wall thickness measurement of large diameter pipes by radiography: 8 and 12 inches, in 12th Asia-Pac. Conf. NDT (A-PCNDT), Auckland, New Zealand, 2006.

Soedardjo, Measurement of insulated pipe thickness with tangential radiography techniques using iridium 192, in Risalah Pertemuan Ilmiah Penelitian dan Pengembangan Teknol. Isotop dan Radiasi, Pusat Pengembangan Tekn-ol. Keselamatan Nuklir,BATAN, Serpong, Indonesia, 2000, pp. 229–235.

Hamzah, A.R., and Amir, S.M.M., Revisited the mathematical derivation wall thickness measurement of pipe for radiography, in Int. Symp. Digital Ind. Radiol. (DIR) Comput. Tomogr. (CT), Lyon, France, 2007.

Rakvin, M., Markucic, D., and Hizman B., Evaluation of pipe wall thickness based on contrast measurement using computed radiography (CR), 24th DAAAM Int. Symp. Intell. Manuf. Autom., Procedia Eng., 2013, no. 69, pp. 1216–1224.

Rasiawan and Wahyudi, M.T., Making of X-Ray Radiography Exposure Chart for Aluminum, Surabaya, Indonesia: Politek. Perkapalan Negeri Surabaya (PPNS-ITS).

Hendroprasetyo, W., Radiographic Testing General, Training Handout: Radiography Testing Level II, Surabaya, Indonesia: NDE Center ITS, 2009.

Moore, P.O., Bossi, R.H., Iddings, F.A., and Wheeler, G.C., Nondestructive Testing Handbook: Radiographic Testing, Ohio, USA: Am. Soc. Nondestr. Test., 2002, vol. 4, 3rd ed.

ASME Boiler and Pressure Vessel Code, Nondestructive Examination, New York: Am. Soc. Mech. Eng., 2010, sec. V, article 2.

ACKNOWLEDGMENTS

The authors gratefully acknowledge the Department of Materials and Metallurgical Engineering ITS and PT Spektra Megah Semesta for providing laboratory facilities. The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Eko Prasetyo, Pariaman, H. & Sulistijono Tangential X-Ray Radiography for Pitting Geometry Analysis of Outside Wall of Insulated Steel Pipes. Russ J Nondestruct Test 56, 249–258 (2020). https://doi.org/10.1134/S1061830920030031

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061830920030031