Abstract

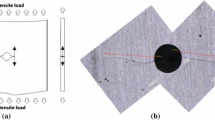

Experiments have been carried out to study the effect of the size and shape of cutouts in steel plates on the difference in the arrival time of acoustic emission pulses at receiving transducers. The data obtained were compared with the results of a numerical simulation of the propagation of elastic waves in plates with various strip and circular cutouts. The research results indicate that the shape of the cutout has a much lesser effect on the time of recording pulses by the transducers of an antenna array than the size of the cutout and the location of the receiving transducer relative to the shading zone—the edge of the cut-out. Based on the results of studies in a 40-mm–thick steel plate with a central 100 mm hole, the accuracy of locating an acoustic emission source near the edge of the hole was estimated. Studies have shown that, in this case, to reduce the measurement error to less than 10% of the antenna-array base size, the location group must include at least four transducers. Numerical simulation of the propagation of acoustic emission pulses in plates with strip and circular cutouts made it possible to significantly reduce the volume of experimental studies, while increasing their information content.

Similar content being viewed by others

REFERENCES

Rules for organizing and conducting acoustic emission monitoring of vessels, apparatuses, boilers and process pipelines (ПБ 03-593-03), Normativnye dokumenty mezhotraslevogo primeneniya po voprosam promyshlennoi bezopasnosti i okhrany nedr (Regulatory Documents of Intersectoral Application on Industrial Safety and Subsoil Protection), Moscow: NTTs Prom. Bezop., 2003, ser. 03, no. 38.

GOST (State Standard) R ISO 22096—2015. Condition monitoring and machine diagnostics. Acoustic emission method, Moscow: Standartinform, 2015.

Ivanov, V.I. and Barat, V.A., Akustiko-emissionnaya diagnostika (Acoustic Emission Diagnostics), Moscow: Spektr, 2017.

Ser’eznov, A.N., Stepanova, L.N., Kabanov, S.I., et al., Akustiko-emissionnyi kontrol’ aviatsionnykh konstruktsii (Acoustic Emission Testing of Aircraft Structures), Stepanova, L.N. and Ser’eznov, A.N., Eds., Moscow: Mashinostroenie-Polet, 2008.

Eaton, M.J., Pullin, R., and Holford, K.M., Acoustic emission source location in composite materials using Delta T Mapping, Composites, Part A, 2012, vol. 43, no. 6, pp. 856–863.

Baxter, M.G., Pullin, R., Holford, K.M., and Evans, S.L., Delta T source location for acoustic emission, Mech. Syst. Signal Process., 2007, vol. 21, no. 3, pp. 1512–1520.

Al-Jumaili, S.K., Pearson, M.R., Holford, K.M., Eaton, M.J., and Pullin, R., Acoustic emission source location in complex structures using full automatic delta T mapping technique, Mech. Syst. Signal Process., 2016, vols. 72–73, pp. 513–524.

Gollob, S. and Vogel, T., Updating cracks within a heterogeneous numerical model based on estimated AE source locations, in Progr. Acoust. Emission XVIII.JSNDI & III AE, Kyoto, 2016, pp. 281–285.

Sause, M.G.R., Modeling of acoustic emission sources in fiber reinforced composites, in Progr. Acoust. Emission XVIII. JSNDI-23 & III AE, Kyoto, 2016, pp. 305–310.

Hallquist, J.O., LS-DYNA Theoretical Manual, Livermore Software Technol. Corp., 2006.

Fedorova, N.N., Val’ger, S.A., Danilov, M.N., and Zakharova, Yu.V., Osnovy raboty v ANSYS 17 (The Basics of Working in ANSYS 17), Moscow: DMK Press, 2017.

Nemirovich-Danchenko, M.M. and Shatskaya, A.A., Modeling of seismic field in a porous medium containing a single pore or a porous layer, Fiz. Mezomekh., 2013, no. 3, pp. 101–104.

Bershtein, M.L. and Zaimanovskii, V.A., Mekhanicheskie svoistva metallov (Mechanical Properties of Metals), Moscow: Metallurgiya, 1989.

Fizika vzryva. V 2 t. (Explosion Physics. 2 Vols.), Orlenko, L.P., Ed., Moscow: Fizmatlit, 2006, Vol. 1.

Electronic resource https://www.dynamore.de/en/downloads/infodays/dokumente/2014-Aku-ppt/3-dynamore-info-akuhuang-et-al.pdf

Ricci, F. et al., Ultrasonic guided waves for hidden damage detection in composite structures, in Nondestr. Test. Mater. Struct. Proc. NDTMS, Istanbul, 2011, pp. 579–584.

Markovic, N., Numerical modeling of ultrasonic wave propagation—by using of explicit fem in abaqus, Archit. Civ. Eng., 2018, vol. 16, no. 1, pp. 135–147.

Funding

This work was supported by the Russian Science Foundation, project no. 18-19-00351.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by V. Potapchouck

Rights and permissions

About this article

Cite this article

Matvienko, Y.G., Vasil’ev, I.E., Bubnov, M.A. et al. Influence of Dimensions and Shape of Process Cutouts on the Accuracy of Locating Acoustic Emission Sources. Russ J Nondestruct Test 56, 101–109 (2020). https://doi.org/10.1134/S1061830920020060

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061830920020060