Abstract

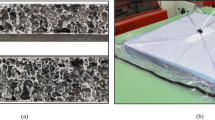

Results of applying a Lamb-wave-based ultrasonic technique to detect impact damages to a CFRP honeycomb panel are presented. The technique is based on analyzing changes in wave propagation due to defects and makes use of a network of piezoelectric transducers adhesively bonded to the panel surface. Preliminary experiments and tests have been carried out in which defect simulators (metal discs attached at various points of the CFRP panel) and low energy impact damages inflicted by drop-weight operation were detected. Results of defect location (calculated coordinates) are considered, as well as a damage index. A detailed analysis of the results has made it possible to identify the specific features and shortcomings of the technique. Possible ways are proposed for eliminating these shortcomings and upgrading the methodology of ultrasonic data processing in general.

Similar content being viewed by others

References

Farrar, C.R. and Worden, K., An introduction to structural health monitoring, Philos. Trans. R. Soc., A, 2007, vol. 365, no. 1851, pp. 303–315. doi https://doi.org/10.1098/rsta.2006.1928

Diamanti, K. and Soutis, C., Structural health monitoring techniques for aircraft composite structures, Prog. Aeronaut. Sci., 2010, vol. 46, no. 8, pp. 342–352. doi https://doi.org/10.1016/j.paerosci.2010.05.001

Liu W., Tang B., Jiang Y. Status and problems of wind turbine in China, Renewable Energy, 2010, vol. 35, no. 7, pp. 1414–1418. doi https://doi.org/10.1016/j.renene.2010.01.006

Schubel, P.J., Crossley, R.J., Boateng, E.K.G., and Hutchinson, J.R., Review of structural health and cure monitoring techniques for large wind turbine blades, Renewable Energy, 2013, vol. 51, pp. 113–123. doi https://doi.org/10.1016/j.renene.2012.08.072

Makhsidov, V.V. and Reznikov, V.A., Projects aimed at the development of technology for the embedded control of structures made of PCM, Nov. Materialoved. Nauka Tekh., 2017, vol. 28, nos. 5–6, pp. 30–37.

Giurgiutiu, V. and Cuc, A., Embedded non-destructive evaluation for structural health monitoring, damage detection, and failure prevention, Shock Vib. Dig., 2005, vol. 37, no. 2, pp. 83–105. doi https://doi.org/10.1177/0583102405052561

Güemes, A., Fernández-López, A., Díaz-Maroto, P., et al., Structural health monitoring in composite structures by fiber-optic sensors, Sensors, 2018, vol. 18, no. 4, pp. 1094. doi https://doi.org/10.3390/s18041094

Eleftheroglou, N., Zarouchas, D., Loutas, T., et al., Structural health monitoring data fusion for in-situ life prognosis of composite structures, Reliab. Eng. Syst. Saf., 2018, vol. 178, pp. 40–54. doi https://doi.org/10.1016/j.ress.2018.04.031

Shilova, A., Wildemann, V., Lobanov, D., and Lyamin, Yu., Experimental study of the effect of fabric high temperature treatment on the composite strength properties, PNRPU Mech. Bull., 2014, vol. 1, pp. 221–239. doi https://doi.org/10.15593/perm.mech/2014.4.09

Tsepennikov, M., Strom, A., Povyshev, I., and Smetannikov, O., Theoretical-experimental study of mechanical behavior in 3D composites under quasi-steady damage, PNRPU Mech. Bull., 2016, vol. 1, pp. 143–158. doi https://doi.org/10.15593/perm.mech/2016.2.10

Barsuk, V.E., Stepanova, L.N., Chernova, V.V., and Kuleshov, V.K. Acoustic emission control of defects during cyclic loading of samples of carbon fiber with shock damage, Konstr. Kompoz. Mater., 2018, vol. 149, no. 1, pp. 69–75.

Barsuk, V.E., Stepanova, L.N., and Kabanov, S.I., Composite airplane construction acoustic emission testing during static loading, Kontrol Diagn., 2018. P. 14–19. doi https://doi.org/10.14489/td.2018.04.pp.014-019

Stepanova, L.N., Bataev, V.A., and Chernova, V.V., Studying the failure of a CFRP sample under static loading by the acoustic-emission and fractography methods, Russ. J. Nondestr. Test., 2017, vol. 53, no. 6, pp. 422–429. doi https://doi.org/10.1134/S1061830917060092

Panozzo, F., Zappalorto, M., Maragoni, L., et al., Modelling the electrical resistance change in a multidirectional laminate with a delamination, Compos. Sci. Technol., 2018, vol. 162, pp. 25–234. doi https://doi.org/10.1016/j.compsci-tech.2018.04.031

Baghalian, A., Senyurek, V.Y., Tashakori, S., et al., Novel nonlinear acoustic health monitoring approach for detecting loose bolts, J. Nondestr. Eval, 2018, vol. 37, no. 2, p. 24. doi https://doi.org/10.1007/s10921-018-0478-0

Potapov, A.I. and Makhov, V.E., Methods for nondestructive testing and diagnostics of durability of articles made of polymer composite materials, Russ. J. Nondestr. Test., 2018, vol. 54, no. 3, pp. 151–163.

Bhalla, S. and Kaur, N., Prognosis of low-strain fatigue induced damage in reinforced concrete structures using embedded piezo-transducers, Int. J. Fatigue, 2018, vol. 113, pp. 98–112. doi https://doi.org/10.1016/j.ijfatigue.2018.04.002

Witoś, M., Zieja, M., Fallahi, N., et al., NDE and SHM of critical parts using magnetic and electromagnetic methods, Acta Phys. Pol., A, 2018, vol. 133, no. 3, pp. 697–700. doi https://doi.org/10.12693/APhysPolA.133.697

Choi, Y., Abbas, S.H., and Lee, J.-R., Aircraft integrated structural health monitoring using lasers, piezoelectricity, and fiber optics, Measurement, 2018, vol. 125, pp. 294–302. doi https://doi.org/10.1016/j.measurement.2018.04.067

Ignatovich, S.R., Menou, A., Karuskevich, M.V., and Maruschak, P.O., Fatigue damage and sensor development for aircraft structural health monitoring, Theor. Appl. Fract. Mech., 2013, vol. 65, pp. 23–27. doi https://doi.org/10.1016/j.tafmec.2013.05.004

Panin, S., Burkov, M., Lyubutin, P., and Altukhov, Y., Application of aluminum foil for “strain sensing” at fatigue damage evaluation of carbon fiber composite, Sci. China: Phys., Mech. Astron., 2014, vol. 57, no. 1, pp. 59–64. doi https://doi.org/10.1007/s11433-013-5368-y

Panin, S.V., Burkov, M.V., Lyubutin, P.S., Altukhov, Y.A., and Shakirov, I.V., Fatigue damage evaluation of carbon fiber composite using aluminum foil based strain sensors, Eng. Fract. Mech., 2014, vol. 129, no. 1, pp. 45–53. doi https://doi.org/10.1016/j.engfracmech.2014.01.003

Wang, P., Takagi, T., Takeno, T., and Miki, H., Early fatigue damage detecting sensors—a review and prospects, Sens. Actuators, A, 2013, vol. 198, pp. 46–60. doi https://doi.org/10.1016/j.sna.2013.03.025

Gomes, G.F., Mendéz, Y.A.D., da Silva Lopes Alexandrino, P., et al. The use of intelligent computational tools for damage detection and identification with an emphasis on composites, Compos. Struct., 2018, vol. 196, pp. 44–54. doi https://doi.org/10.1016/j.compstruct.2018.05.002

Makhsidov, V.V., Yakovlev, N.O., Il’ichev, A.V., Shienok, A.M., and Firsov, L.L., Determining the deformation of PCM construction material with integrated fiber-optic sensors, Mekh. Kompoz. Mater. Strukt., 2016, vol. 22, no. 3, pp. 402–413.

Bashkov, O.V., Romashko, R.V., Zaikov, V.I., et al., Detecting acoustic-emission signals with fiber-optic interference transducers, Russ. J. Nondestr. Test., 2017, vol. 53, no. 6, pp. 415–421. doi https://doi.org/10.1134/S1061830917060031

Cho, H. and Lissenden, C.J., Structural health monitoring of fatigue crack growth in plate structures with ultrasonic guided waves, Struct. Health Monit., 2012, vol. 11, no. 4, pp. 393–404. doi https://doi.org/10.1177/1475921711430439

Glushkov, E.V., Glushkova, N.V., and Eremin, A.A., Guided wave based nondestructive testing and evaluation of effective elastic moduli of layered composite materials, Mater. Phys. Mech., 2015, vol. 23, pp. 56–60.

Lunev, A., Nadezhkin, M., and Zuev, L., Velocity and attenuation of ultrasound waves under cyclic loading of low-carbon steel, in Proc. Int. Conf. Adv. Mater. Hierarchical Struct. New Technol. Reliab. Struct., Tomsk, Russia, September 19–26, 2016, p. 20140. doi https://doi.org/10.1063/1.496643310.1063/1.4966433

Samokrutov, A. and Shevaldykin, V., Impact induced damage detecting of aircraft CFRP covering by acoustic testing, NDT World, 2015, vol. 19, no. 4, pp. 29–32. doi https://doi.org/10.12737/23501

Morteau, E. and Fualdes, C., Use of probabilistic methods, in FAA Bombardier Ind. Compos. Transp. Damage Tolerance Maint. Workshop ESCAC, September 2015, Dorval, Quebec, Canada.

Sherafat, M.H., Guitel, R., Quaegebeur, N., Hubert, P., Lessard, L., and Masson, P., Structural health monitoring of a composite skin-stringer assembly using within-the-bond strategy of guided wave propagation, Mater. Des., 2016, vol. 90, pp. 787–794. doi https://doi.org/10.1016/j.matdes.2015.11.018

Flynn, E.B. and Todd, M.D., A Bayesian approach to optimal sensor placement for structural health monitoring with application to active sensing, Mech. Syst. Signal Process., 2010, vol. 24, no. 4, pp. 891–903. doi:https://doi.org/10.1016/j.ymssp.2009.09.003

Lee, B.C. and Staszewski, W.J., Sensor location studies for damage detection with Lamb waves, Smart Mater. Struct., 2007, vol. 16, no. 2, pp. 399–408. doi https://doi.org/10.1088/0964-1726/16/2/019

Moore, E.Z., Murphy, K.D., and Nichols, J.M., Optimized sensor placement for damage parameter estimation: experimental results for a cracked plate, Struct. Health Monit., 2013, vol. 12, no. 3, pp. 197–206. doi https://doi.org/10.1177/1475921713476330

Nedospasov, I.A., Mozhaev, V.G., and Kuznetsova, I.E., Unusual energy properties of leaky backward Lamb waves in a submerged plate, Ultrasonics, 2017, vol. 77, pp. 95–99. doi https://doi.org/10.1016/j.ultras.2017.01.025

Park, I., Jun, Y., and Lee, U., Lamb wave mode decomposition for structural health monitoring, Wave Motion, 2014, vol. 51, no. 2, pp. 335–347. doi https://doi.org/10.1016/j.wavemoti.2013.09.004

Eremin, A.A., Viscosity-driven attenuation of elastic guided waves in layered composite structures, Mater. Phys. Mech., 2018, vol. 37, no. 1, pp. 42–51.

Attarian, V.A., Cegla, F.B., and Cawley, P., Long-term stability of guided wave structural health monitoring using distributed adhesively bonded piezoelectric transducers, Struct. Health Monit., 2014, vol. 13, no. 3, pp. 265–280. doi https://doi.org/10.1177/1475921714522842

Schubert, K.J., Brauner, C., and Herrmann, A.S., Non-damage-related influences on Lamb wave-based structural health monitoring of carbon fiber-reinforced plastic structures, Struct. Health Monit., 2013, vol. 13, no. 2, pp. 158–176. doi https://doi.org/10.1177/1475921713513975

Wandowski, T., Malinowski, P.H., and Ostachowicz, W.M., Delamination detection in CFRP panels using EMI method with temperature compensation, Compos. Struct., 2016, vol. 151, pp. 99–107. doi https://doi.org/10.1016/j.comp-struct.2016.02.056

Dodson, J.C. and Inman, D.J. Thermal sensitivity of Lamb waves for structural health monitoring applications, Ultrasonics, 2013, vol. 53, no. 3, pp. 677–685. doi https://doi.org/10.1016/j.ultras.2012.10.007

Kullaa, J., Distinguishing between sensor fault, structural damage, and environmental or operational effects in structural health monitoring, Mech. Syst. Signal Process., 2011, vol. 25, no. 8, pp. 2976–2989. doi https://doi.org/10.1016/j.ymssp.2011.05.017

Hahn, S.L. Hilbert Transforms in Signal Processing, Norwood: Artech House, 1996.

Lyons, R.G., Understanding Digital Signal Processing, Upper Saddle River: Prentice Hall PTR, 2001.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Burkov, M.V., Lyubutin, P.S. & Byakov, A.V. Lamb Wave Ultrasonic Detection of Barely Visible Impact Damages of CFRP. Russ J Nondestruct Test 55, 89–101 (2019). https://doi.org/10.1134/S1061830919020025

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061830919020025