Abstract

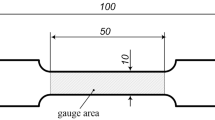

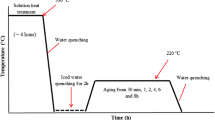

Possibilities offered by an ultrasonic inspection technique that is based on using Lamb waves for monitoring the state of metal materials under static and cyclic loading have been studied. Dogbone V96ts3T12-aluminum-alloy specimens of the following two types have been used for research: initial material and a sample with a weld at the working zone center. The digital-image correlation method has been used as an additional source of information. Based on the tests, dependences of various informative parameters of acoustic vibrations on the applied load (for static tests) and running time (for cyclic tests) have been obtained. These dependences have been further supplemented with the results of calculation of deformation fields. The data gathered indicate sensitivity of the proposed ultrasonic inspection technique to various (elastic and plastic) deformation processes and allow one to monitor the growth of cracks under cyclic tests. Further development of the method assumes its examination from the viewpoint of embedded testing systems (the Structural Health Monitoring concept).

Similar content being viewed by others

References

Farrar, C.R. and Worden, K., An introduction to structural health monitoring, Philos. Trans. R. Soc., Ser. A: Math. Phys. Eng. Sci., 2007, vol. 365, no. 1851, pp. 303–315. doi 10.1098/rsta.2006.1928

Diamanti, K. and Soutis, C., Structural health monitoring techniques for aircraft composite structures, Progr. Aerosp. Sci., 2010, vol. 46, no. 8, pp. 342–352. doi 10.1016/j.paerosci.2010.05.001

Liu, W., Tang, B., and Jiang, Y., Status and problems of wind turbine structural health monitoring techniques in China, Renewable Energy, 2010, vol. 35, no. 7, pp. 1414–1418. doi 10.1016/j.renene.2010.01.006

Schubel, P.J., Crossley, R.J., Boateng, E.K.G., and Hutchinson, J.R., Review of structural health and cure monitoring techniques for large wind turbine blades, Renewable Energy, 2013, vol. 51, pp. 113–123. doi 10.1016/j.renene.2012.08.072

Ignatovich, S.R., Menou, A., Karuskevich, M.V., and Maruschak, P.O., Fatigue damage and sensor development for aircraft structural health monitoring, Theor. Appl. Fract. Mech., 2013, vol. 65, pp. 23–27. doi 10.1016/j.tafmec.2013.05.004

Panin, S., Burkov, M., Lyubutin, P., and Altukhov, Y., Application of aluminum foil for “strain sensing” at fatigue damage evaluation of carbon fiber composite, Sci. China: Phys. Mech. Astron., 2014, vol. 57, no. 1, pp. 59–64. doi 10.1007/s11433-013-5368-y

Panin, S.V., Burkov, M.V., Lyubutin, P.S., Altukhov, Y.A., and Shakirov, I.V., Fatigue damage evaluation of carbon fiber composite using aluminum foil based strain sensors, Eng. Fract. Mech., 2014, vol. 129, no. 1, pp. 45–53. doi 10.1016/j.engfracmech.2014.01.003

Wang, P., Takagi, T., Takeno, T., and Miki, H., Early fatigue damage detecting sensors —a review and prospects, Sens. Actuators, A: Phys., 2013, vol. 198, pp. 46–60. doi 10.1016/j.sna.2013.03.025

Cho, H. and Lissenden, C.J., Structural health monitoring of fatigue crack growth in plate structures with ultrasonic guided waves, Struct. Health Monit., 2012, vol. 11, no. 4, pp. 393–404. doi 10.1177/1475921711430439

Glushkov, E.V., Glushkova, N.V., and Eremin, A.A., Guided wave based nondestructive testing and evaluation of effective elastic moduli of layered composite materials, Mater. Phys. Mech., 2015, vol. 23, pp. 56–60.

Lunev, A., Nadezhkin, M., and Zuev, L., Velocity and attenuation of ultrasound waves under cyclic loading of low-carbon steel, Proc. Int. Conf. Adv. Mater. Hierarchical Struct. New Technol. Reliab. Struct., September 19–26, 2016, Tomsk, p. 20140. doi 10.1063/1.496643310.1063/1.4966433

Sherafat, M.H., Guitel, R., Quaegebeur, N., Hubert, P., Lessard, L., and Masson, P., Structural health monitoring of a composite skin-stringer assembly using within-the-bond strategy of guided wave propagation, Mater. Des., 2016, vol. 90, pp. 787–794. doi 10.1016/j.matdes.2015.11.018

Flynn, E.B. and Todd, M.D., A Bayesian approach to optimal sensor placement for structural health monitoring with application to active sensing, Mech. Syst. Signal Process., 2010, vol. 24, no. 4, pp. 891–903. doi 10.1016/j.ymssp.2009.09.003

Lee, B.C. and Staszewski, W.J., Sensor location studies for damage detection with Lamb waves, Smart Mater. Struct., 2007, vol. 16, no. 2, pp. 399–408. doi 10.1088/0964-1726/16/2/019

Moore, E.Z., Murphy, K.D., and Nichols, J.M., Optimized sensor placement for damage parameter estimation: experimental results for a cracked plate, Struct. Health Monit., 2013, vol. 12, no. 3, pp. 197–206. doi 10.1177/1475921713476330

Nedospasov, I.A., Mozhaev, V.G., and Kuznetsova, I.E., Unusual energy properties of leaky backward Lamb waves in a submerged plate, Ultrasonics, 2017, vol. 77, pp. 95–99. doi 10.1016/j.ultras.2017.01.025

Park, I., Jun, Y., and Lee, U., Lamb wave mode decomposition for structural health monitoring, Wave Motion, 2014, vol. 51, no. 2, pp. 335–347. doi 10.1016/j.wavemoti.2013.09.004

Attarian, V.A., Cegla, F.B., and Cawley, P., Long-term stability of guided wave structural health monitoring using distributed adhesively bonded piezoelectric transducers, Struct. Health Monit., 2014, vol. 13, no. 3, pp. 265–280. doi 10.1177/1475921714522842

Schubert, K.J., Brauner, C., and Herrmann, A.S., Non-damage-related influences on Lamb wave-based structural health monitoring of carbon fiber-reinforced plastic structures, Struct. Health Monit., 2013, vol. 13, no. 2, pp. 158–176. doi 10.1177/1475921713513975

Wandowski, T., Malinowski, P.H., and Ostachowicz, W.M., Delamination detection in CFRP panels using EMI method with temperature compensation, Compos. Struct., 2016, vol. 151, pp. 99–107. doi 10.1016/j.compstruct. 2016.02.056

Dodson, J.C. and Inman, D.J., Thermal sensitivity of Lamb waves for structural health monitoring applications, Ultrasonics, 2013, vol. 53, no. 3, pp. 677–685. doi 10.1016/j.ultras.2012.10.007

Kullaa, J., Distinguishing between sensor fault, structural damage, and environmental or operational effects in structural health monitoring, Mech. Syst. Signal Process., 2011, vol. 25, no. 8, pp. 2976–2989. doi 10.1016/j.ymssp.2011.05.017

Hahn, S.L., Hilbert Transforms in Signal Processing, Norwood: Artech House, 1996.

Eremin, A., Byakov, A., Panin, S., Burkov, M., Lyubutin, P., and Sunder, R., Application of a Lamb waves based technique for structural health monitoring of GFRP under cyclic loading, IOP Conf. Ser.: Mater. Sci. Eng., 2016, vol. 124, p. 12084. doi 10.1088/1757-899X/124/1/012084

Wildemann, V.E., Spaskova, E.V., and Shilova, A.I., Research of the damage and failure processes of composite materials based on acoustic emission monitoring and method of digital image correlation, Solid State Phenom., 2015, vol. 243, pp. 163–170. 10.4028/www.scientific.net/SSP.243.163

Staszewski, W.J., Lee, B.C., Mallet, L., and Scarpa, F., Structural health monitoring using scanning laser vibrometry: I. Lamb wave sensing, Smart Mater. Struct., 2004, vol. 13, no. 2, pp. 251–260. doi 10.1088/0964- 1726/13/2/002

Burkov, M.V., Eremin, A.V., Byakov, A.V., Shah, R.T., Lyubutin, P.S., and Panin, S.V., Lamb wave based ultrasonic technique for AA2024 fatigue evaluation, Key Eng. Mater., 2016, vol. 685, pp. 399–402. doi 10.4028/www.scientific.net/KEM.685.399

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © M.V. Burkov, A.V. Eremin, P.S. Lyubutin, A.V. Byakov, S.V. Panin, 2017, published in Defektoskopiya, 2017, No. 12, pp. 3–15.

Rights and permissions

About this article

Cite this article

Burkov, M.V., Eremin, A.V., Lyubutin, P.S. et al. Applying an Ultrasonic Lamb Wave Based Rechnique to Testing the Condition of V96ts3T12 Aluminum Alloy. Russ J Nondestruct Test 53, 817–829 (2017). https://doi.org/10.1134/S1061830917120038

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061830917120038