Abstract

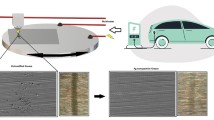

The possibilities of using the eddy-current method for testing the fatigue degradation under contact loading of NiCrBSi coatings were investigated. These coatings are obtained using the method of the gas–powder laser cladding from powders with different contents of chromium, boron, carbon, and additives of titanium carbide TiC (15 and 25 wt. %). It was established that eddy-current testing of fatigue degradation under contact loading of PG-SR2 and PG-10N-01 coatings can be performed at high excitation frequencies of an eddy-current transducer, when the depth of the analyzed layer is maximally close to the thickness of the surface layer that was subjected to fatigue degradation. Testing the fatigue degradation under contact loading of TiC–PG-SR2 composite coatings with TiC-additive contents of 15 and 25 wt. % has certain limitations and features that result from the presence of a significant number of discontinuity flaws in the structure of these coatings.

Similar content being viewed by others

References

Orlov, A.V., Chermenskii, O.N., and Nesterov, V.M., Ispytaniya konstruktsionnykh materialov na kontaktnuyu ustalost' (Contact-Fatigue Tests of Structural Materials), Moscow: Mashinostroenie, 1980.

Jia, H., Wu, X., Liu, X., Liu, C., and Wang, Z., Analysis and research of acoustic emission signal of rolling element bearing fatigue, Chapter in book: Advances in Acoustic Emission Technology: Proc. of the World Conf. on Acoustic Emission-2013, Eds. Shen, G., Wu, Z., and Zhang, J., Springer Proc. in Physics, 2015, vol. 158, pp. 157–166.

Nohál, L., Hort, F., Dvořáček, J., and Mazal, P., An experimental investigation of rolling contact fatigue of steels using acoustic emission method, Insight: Non-Destruct. Test. Condition Monitor., 2013, vol. 55, no. 12, pp. 665–669.

Piao, Z.-Y., Xu, B.-S., Wang, H.-D., and Wen, D.-H., Investigation of acoustic emission source of Fe-based sprayed coating under rolling contact, Int. J. Fatig., 2013, vol. 47, pp. 184–188.

Guo-Lu, L., Zhi-Qiang, Z., Hai-Dou, W., Bin-Shi, X., Zhong-Yu, P., and Li-Na, Z., Acoustic emission monitoring and failure mechanism analysis of rolling contact fatigue for Fe-based alloy coating, Tribol. Int., 2013, vol. 61, pp. 129–137.

Mazal, P., Dvoracek, J., and Pazdera, L., Application of acoustic emission method in contact damage identification, Int. J. Mater. Prod. Technol., 2011, vol. 41, nos. 1–4, pp. 140–152.

Piao, Z.-Y., Xu, B.-S., Wang, H.-D., and Pu, C.-H., Investigation of fatigue failure prediction of Fe–Cr alloy coatings under rolling contact based on acoustic emission technique, Appl. Surf. Sci., 2011, vol. 257, pp. 2581–2586.

Rahman, Z., Ohba, H., Yoshioka, T., and Yamamoto, T., Incipient damage detection and its propagation monitoring of rolling contact fatigue by acoustic emission, Tribol. Int., 2009, vol. 42, pp. 807–815.

Thomas, H.-M., Dey, A., and Heyder, R., Eddy current test method for early detection of rolling contact fatigue (RCF) in rails, Insight: Non-Destr. Test. Condition Monitor., 2010, vol. 52, no. 7, pp. 361–365.

Nicholas, M.J. and Hope, A.D., High-speed detection of rolling contact fatigue in railway rails, Insight: NonDestr. Test. Condition Monitor., 2006, vol. 48, no. 6, pp. 346–347.

Chacón Muñoz, J.M., García Márquez, F.P., and Papaelias, M., Railroad inspection based on ACFM employing a non-uniform B-spline approach, Mech. Syst. Sign. Process., 2013, vol. 40, no. 2, pp. 605–617

Rowshandel, H., Nicholson, G.L., Davis, C.L., and Roberts, C., A robotic approach for NDT of RCF cracks in rails using an ACFM sensor, Insight: Non-Destr. Test. Condition Monitor., 2011, vol. 53, no. 7, pp. 368–376.

Wilson, J., Tian, G., Mukriz, I., and Almond, D., PEC thermography for imaging multiple cracks from rolling contact fatigue, NDT and E Int., 2011, vol. 44, no. 6, pp. 505–512.

Deneuville, F., Duquennoy, M., Ouaftouh, OurakM., Jenot, F., and Desvaux, S., High-frequency ultrasonic detection of C-crack defects in silicon nitride bearing balls, Ultrasonics, 2009, vol. 49, pp. 89–93.

Pau, M., Leban, B., and Baldi, A., Simultaneous subsurface defect detection and contact parameter assessment in a wheel-rail system, Wear, 2008, vol. 265, pp. 1837–1847.

Edwards, R.S., Holmes, C., Fan, Y., Papaelias, M., Dixon, S., Davis, C.L., Drinkwater, B.W., and Roberts, C., Ultrasonic detection of surface-breaking railhead defects, Insight: Non-Destr. Test. Condition Monitor., 2008, vol. 50, no. 7, pp. 369–373.

Edwards, R.S., Dixon, S., Fan, Y., and Jian, X., EMAT measurements of inand out-of-plane ultrasonic signals, AIP Conf. Proc., 2008, vol. 975, pp. 841–848.

Yoshioka, T. and Shimizu, S., Monitoring of ball bearing operation under grease lubrication using a new compound diagnostic system detecting vibration and acoustic emission, Tribol. Transact., 2009, vol. 52, no. 6, pp. 725–730.

Aurichio, T., Cumino, R., de Oliveira, C.D.M., Dourado, L., and Silva, W.S., Contact fatigue wear evaluation of thrust rolling bearings lubricated with greases with molybdenum disulfide or graphite, SAE Int. J. Fuels Lubric., 2010, vol. 3, no. 2, pp. 386–394.

Thomas, H.-M., Heckel, T., and Hanspach, G., Advantage of a combined ultrasonic and eddy current examination for railway inspection trains, Insight: Non-Destr. Test. Condition Monitor., 2007, vol. 49, no. 6, pp. 341–344.

Tushinskii, L.I., Bataev, V.A., Potapov, V.M., Bataev, A.A., and Timofeev, A.P., Life of hardened materials under the conditions of contact load, Met. Sci. Heat Treat., 1988, vol. 30, no. 5, pp. 363–365.

Tarrés, E., Ramírez, G., Gaillard, Y., Jiménez-Piqué, E., and Llanes, L., Contact fatigue behavior of PVDcoated hard metals, Int. J. Refract. Met. Hard Mater., 2009, vol. 27, pp. 323–331.

Bataev, I.A., Bataev, A.A., Golkovski, M.G., Krivizhenko, D.S., Losinskaya, A.A., and Lenivtseva, O.G., Structure of surface layers produced by nonvacuum electron beam boriding, Appl. Surf. Sci., 2013, vol. 284, pp. 472–481.

Savrai, R.A., Makarov, A.V., Soboleva, N.N., Malygina, I.Yu., and Osintseva, A.L., The contact endurance of NiCrBSi coatings obtained by gas powder laser cladding, Obrab. Metal.: Tekhnol., Oborud., Instrum., 2014, no. 4 (65), pp. 43–51.

Latella, B.A., Atanacio, A.J., and Liu, T., Fatigue damage mechanisms in CeO-stabilized tetragonal ZrO2, J. Mater. Sci. Lett., 2002, vol. 21, no. 11, pp. 879–882.

Pinegin, S.V., Kontaktnaya prochnost’ v mashinakh (Contact Strength in Machines), Moscow: Mashinostroenie, 1965.

Makarov, A.V., Korshunov, L.G., Malygina, I.Yu., and Osintseva, A.L., Effect of laser quenching and subsequent heat treatment on the structure and wear resistance of a cemented steel 20KhN3A, Phys. Met. Metallogr., 2007, vol. 103, no. 5, pp. 507–518.

Makarov, A.V., Gorkunov, E.S., Malygina, I.Yu., Kogan, L.Kh., Savrai, R.A., and Osintseva, A.L., Eddy-current testing of the hardness, wear resistance, and thickness of coatings prepared by gas–powder laser cladding, Russ. J. Nondestr. Test., 2009, vol. 45, no. 11, pp. 797–805.

Makarov, A.V., Gorkunov, E.S., and Kogan, L.Kh., Application of the eddy-current method for estimating the wear resistance of hydrogen-alloyed-titanium BT35 alloy, Russ. J. Nondestr. Test., 2007, vol. 43, no. 1, pp. 21–26.

Bakunov, A.S., Muzhitskii, V.F., and Shubochkin, S.E., A modern solution to problems of eddy-current structuroscopy, Russ. J. Nondestr. Test., 2004, vol. 40, no. 5, pp. 346–349.

Makarov, A.V., Gorkunov, E.S., Savrai, R.A., Kogan, L.Kh., Yurovskikh, A.S., Kolobylina, Yu.M., Malygina, I.Yu., and Davydova, N.A., The influence of a combined strain–heat treatment on the features of electromagnetic testing of fatigue degradation of quenched constructional steel, Russ. J. Nondestr. Test., 2013, vol. 49, no. 12, pp. 690–704.

Makarov, A.V., Savrai, R.A., Gorkunov, E.S., Malygina, I.Yu., Kogan, L.Kh., Pozdeeva, N.A., and Kolobylin, Yu.M., Effect of friction-induced hardening on the features of magnetic and eddy-current behavior of an annealed structural steel under cyclic loading conditions, Russ. J. Nondestr. Test., 2008, vol. 44, no. 7, pp. 496–508.

Gorkunov, E.S., Savrai, R.A., Makarov, A.V., Kogan, L.Kh., and Rogovaya, S.A., Application of an eddy-current method for the assessment of stored plastic deformation and residual mechanical properties after cyclic loading of an annealed medium-carbon steel, Russ. J. Nondestr. Test., 2007, vol. 43, no. 4, pp. 228–233.

Makarov, A.V., Gorkunov, E.S., Kogan, L.Kh., and Malygina, I.Yu., Estimation of the quality of strengthening frictional treatment and subsequent tempering of eutectoid steel by the eddy-current method, Russ. J. Nondestr. Test., 2009, vol. 45, no. 2, pp. 133–142.

Makarov, A.V., Gorkunov, E.S., Savrai, R.A., Kolobylin, Yu.M., Kogan, L.Kh., Yurovskikh, A.S., Pozdeeva, N.A., and Malygina, I.Yu., The peculiarities of magnetic and eddy-current testing of quenched structural steel hardened by nanostructuring frictional treatment Russ. J. Nondestr. Test., 2012, vol. 48, no. 11, pp. 615–622.

Makarov, A.V., Gorkunov, E.S., Kogan, L.Kh., Kolobylin, Yu.M., Korshunov, L.G., and Osintseva, A.L., Features of electromagnetic methods for testing the wear resistance of medium-carbon structural steel subjected to laser or bulk hardening and tempering, Russ. J. Nondestr. Test., 2006, vol. 42 no. 7, pp. 443–451.

Makarov, A.V., Kogan, L.Kh., Gorkunov, E.S., and Kolobylin, Yu.M., Eddy-current evaluation of wear resistance of case-hardened chromium–nickel 20KhN3A steel, Russ. J. Nondestr. Test., 2001, vol. 37, no. 2, pp. 136–144.

Makarov, A.V., Gorkunov, E.S., Kolobylin, Yu.M., Kogan, L.Kh., Korshunov, L.G., Malygina, I.Yu., and Osintseva, A.L., Eddy-current testing of the wear resistance of laser-hardened carburized chromonickel steel and the quality of laser hardening of drill bits, Russ. J. Nondestr. Test., 2009, vol. 45, no. 10, pp. 698–710.

Makarov, A.V., Gorkunov, E.S., Kogan, L.Kh., Kolobylin, Yu.M., and Osintseva A.L., Eddy-current and coercive-force testing of abrasion-resistant ShKh15 ball bearing steel subjected to laser and bulk thermal processing, Russ. J. Nondestr. Test., 2006, vol. 42, no. 10, pp. 639–647.

Makarov, A.V., Savrai, R.A., Osintseva, A.L., and Malygina, I.Yu., The influence of chemical composition on tribological properties of laser clad CrNi-based coatings, Izv. Chelyabinsk. Nauchn. Tsentra, 2009, no. 2 (44), pp. 28–33.

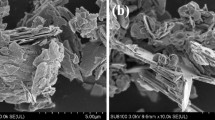

Soboleva, N.N., Malygina, I.Yu., Osintseva, A.L., and Pozdeeva, N.A., Influence of the microstructure and phase composition on the tribological properties of laser coatings, Izv. Samar. Nauch. Tsentra RAN, 2011, vol. 13, no. 4 (3), pp. 869–873.

Makarov, A.V., Soboleva, N.N., Malygina, I.Yu., and Osintseva, A.L., Formation of a NiCrBSi–TiC composite coating with increased abrasive wear resistance by the method of gas–powder laser cladding, Uprochn. Tekhnol. Pokryt., 2013, no. 11 (107), pp. 38–44.

Soboleva, N.N., Makarov, A.V., and Malygina, I.Yu., Hardening frictional treatment of NiCrBSi laser clad coating, Obrab. Metal. (Tekhnol., Oborud., Instrum.), 2013, no. 4 (61), pp. 79–85.

Dawei, Z., Li, T., and Lei, T.C., Laser cladding of Ni–Cr3Cr2/(Ni+Cr), composite coating, Surf. Coat. Technol., 1988, vol. 110, pp. 81–85.

Li, Q., Zhang, D., Lei, T., Chen, Ch., and Chen, W., Comparison of laser-clad and furnace-melted Ni-based alloy microstructures, Surf. Coat. Technol., 2001, vol. 137, pp. 122–135.

Llanes, L., Tarrés, E., Ramírez, G., Botero, C.A., and Jiménez-Piqué, E., Fatigue susceptibility under contact loading of hard metals coated with ceramic films, Proced. Engin., 2010, vol. 2, pp. 299–308.

Ramírez, G., Mestra, A., Casas, B., Valls, I., Martínez, R., Bueno, R., Góez, A., Mateo, A., and Llanes, L., Influence of substrate microstructure on the contact fatigue strength of coated cold-work tool steels, Surf. Coat. Technol., 2012, vol. 206, pp. 3069–3081.

Caron, I., De Monicault, J.M., and Gras, R., Influence of surface-coatings on titanium-alloy resistance to fretting fatigue in cryogenic environment, Tribol. Int., 2001, vol. 34, pp. 217–223.

He, Q., Guo, S., and Liu, W., Analysis of chemical valence of the elements of the oxidized surface layer of a thermally sprayed Ni–Cr coating under fretting, Surf. Coat. Technol., 1998, vol. 106, pp. 91–93.

Dorofeev, A.L., Induktsionnaya strukturoskopiya (Induction Structuroscopy), Moscow: Energiya, 1973.

Dyakin, V.V. and Sandovskii, V.A., Teoriya i raschet nakladnykh vikhretokovykh preobrazovatelei (Theory and Calculation of Attachable EC Transducers), Moscow: Nauka, 1981.

Wijn, H.P.J., Magnetic Properties of Metals. d-Elements, Alloys, and Compounds, Springer Berlin Heidelberg, 1991.

Konyaeva, M.A. and Medvedeva, N.I., Electron structure, magnetic properties, and stability of (Fe, Cr)3C and (Fe, Cr)7C3 binary and ternary carbides, Fiz. Tverd. Tela, 2009, vol. 51, no. 10, pp. 1965–1969.

Kazantseva, N.V., Korolev, A.V., Davydov, D.I., Vinogradova, N.I., Rigmant, M.B., and Stepanova, N.N., Concentration inhomogeneity and magnetism in a blade produced of a refractory nickel alloy, Materialovedenie, 2013, no. 4, pp. 18–24.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © R.A. Savrai, A.V. Makarov, E.S. Gorkunov, L.Kh. Kogan, N.N. Soboleva, I.Yu. Malygina, A.L. Osintseva, 2015, published in Defektoskopiya, 2015, Vol. 51, No. 11, pp. 43–58.

Rights and permissions

About this article

Cite this article

Savrai, R.A., Makarov, A.V., Gorkunov, E.S. et al. Eddy-current testing of fatigue degradation under contact loading of NiCrBSi coatings obtained through gas–powder laser cladding. Russ J Nondestruct Test 51, 692–704 (2015). https://doi.org/10.1134/S1061830915110042

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061830915110042