Abstract

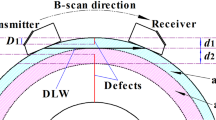

Ultrasonic nondestructive evaluation (NDE) is widely used for detecting flaws in oil pipelines. The backscattering noise may attain peak values greater than the sought flaw pulse. For improving the signal-to-noise ratio (SNR) and extracting a flaw echo corrupted by noise, a resonance demodulation technique and a resonance filter are proposed. The impulse response of the resonance filter can be represented as a superposition of Gaussian echoes. The analysis results show that this approach is more effective in extracting the information of a small flaw during pipeline NDE. The amplitude envelope of the processed ultrasonic signal after envelope detection obtains a notable SNR enhancement.

Similar content being viewed by others

References

Reber, K., Beller, M., Willems, H., et al., A New Generation of Ultrasonic In-Line Inspection Tools for Detecting, Sizing and Locating Metal Loss and Cracks in Transmission Pipelines, Proceedings of the IEEE Ultrasonic Symposium, 2002, vol. 1, pp. 665–671.

Huang, J., Que, P.W., and Jin, J.H., Adaptive Dynamic Focusing System for Ultrasonic Nondestructive Testing of Pipeline Girth Welds, Rev. Sci. Instrum., 2004, vol. 75, no. 5, part 1, pp. 1341–1346.

Honarvar, F., Sheikhzadeh, H., et al., Improving the Time-Resolution and Signal-to-Noise Ratio of Ultrasonic NDE Signals, Ultrasonics, 2004, vol. 41, no. 9, pp. 755–763.

Chen, T.-L., Que, P.-W., Zhang, Q., et al., Ultrasonic Signal Identification by Empirical Mode Decomposition and Hilbert Transform, Rev. Sci. Instrum., 2005, vol. 76, no. 8, pp. 1–6.

Wang, W., Wong, A.K., Some New Signal Processing Approaches for Gear Fault Diagnosis, Proceedings of the Fifth International Symposium on Signal Processing and Its Applications ISSPA’99, 1999, vol. 2, pp. 587–590; Digital Object Identifier 10.1109/ISSPA.1999.815741.

Ruizhong, L., Shanan, Z., Helei, W., et al., Rolling Bearings Fault Diagnosis Based on Energy Operator Demodulation Approach, Proceedings of the 4th World Congress on Intelligent Control and Automation, 2002, vol. 4, pp. 2723–2727; Digital Object Identifier 10.1109/WCICA.2002.1020012.

Cardoso, G. and Saniie, J., Ultrasonic Data Compression via Parameter Estimation, IEEE Trans. Ultrasonics, Ferroelectrics and Frequency Control, 2005, vol. 52, no. 2, pp. 313–325; Digital Object Identifier 10.1109/TUFFC.2005.1406557.

Demirli, R. and Saniie, J., Model-Based Estimation of Ultrasonic Echoes: Part I: Analysis.

Author information

Authors and Affiliations

Additional information

The text was submitted by the authors in English.

Rights and permissions

About this article

Cite this article

Liang, W., Que, PW. & Yang, G. Ultrasonic flaw detection during NDE of oil pipelines via a resonance filter. Russ J Nondestruct Test 42, 398–403 (2006). https://doi.org/10.1134/S1061830906060076

Issue Date:

DOI: https://doi.org/10.1134/S1061830906060076