Abstract

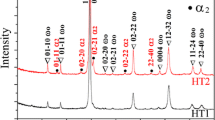

X-ray diffraction studies were conducted to examine changes in the structural-phase state and dislocation density of Ti49.8Ni50.2 alloy depending on the isochronal annealing temperature after severe plastic deformation by abc pressing at 573 K. The total true strain achieved in the alloy specimens during abc pressing was e = 9.55. Isochronal annealing was carried out for 1 h at 573, 673, 773, 873 and 973 K. Analysis of all studied specimens at room temperature revealed the coexistence of R and B19′ phases, whose relative fractions varied with annealing temperature. The high-temperature B2 phase was not detected. It was found that the most rapid decrease in the dislocation density, which was measured at 393 K (in the B2 state), occurred after annealing at 673 and 773 K. Specimens annealed at 773 K had the minimum dislocation density, which is more than an order of magnitude lower than the dislocation density immediately after abc pressing. In the same temperature range, there is a significant decrease in the root-mean-square B2 lattice microdistortions <ε2>1/2 and a slight increase in the average size of coherently diffracting domains (crystallities). After abc pressing and isochronal annealing, the main contribution to the intrinsic X-ray line broadening is made by B2 lattice microdistortions, while the contribution from crystallite size is insignificant. The obtained results show that intense recrystallization in Ti49.8Ni50.2 alloy after abc pressing at 573 K begins at T ≥ 773 K.

Similar content being viewed by others

REFERENCES

Otsuka, K. and Ren, X., Physical Metallurgy of TiNi-Based Shape Memory Alloys, Progr. Mater. Sci., 2005, vol. 50, pp. 511–678. https://doi.org/10.1016/j.pmatsci.2004.10.001

Otsuka, K. and Wayman, C.M., Shape Memory Materials, Cambridge: Cambridge University Press, 1998.

Jani, M., Leary, M., Subic, A., and Gibson, M.A., A Review of Shape Memory Alloy Research, Applications and Opportunities, Mater. Des., 2014, vol. 56, pp. 1078–1113. https://doi.org/10.1016/j.matdes.2013.11.084

Valiev, R.Z., Zhilyaev, A.P., and Langdon, T.G., Bulk Nanostructured Materials: Fundamentals and Applications, New Jersey: Wiley & Sons, 2014.

Valiev, R.Z. and Langdon, T.G., Principles of Equal-Channel Angular Pressing as a Processing Tool for Grain Refinement, Progr. Mater. Sci., 2006, vol. 51, pp. 881–981. https://doi.org/10.1016/j.pmatsci.2006.02.003

Zhang, X., Song, J., Huang, C., Xia, B., Chen, B., Sun, X., and Xie, C., Microstructures Evolution and Phase Transformation Behaviors of Ni-Rich TiNi Shape Memory Alloys after Equal-Channel Angular Extrusion, J. Alloys Compd, 2011, vol. 509, pp. 3006–3012. https://doi.org/10.1016/j.jallcom.2010.11.189

Shamsolhodaei, A., Zarei-Hanzaki, A., and Moghaddam, M., Structural and Functional Properties of a Semi Equiatomic NiTi Shape Memory Alloy Processed by Multi-Axial Forging, Mater. Sci. Eng. A, 2017, vol. 700, pp. 1–9. https://doi.org/10.1016/j.msea.2017.04.011

Kashin, O., Lotkov, A., Grishkov, V., Krukovskii, K., Zhapova, D., Mironov, Y., Girsova, N., Kashina, O., and Barmina, E., Effect of abc Pressing at 573 K on the Microstructure and Martensite Transformation Temperatures in Ti49.8Ni50.2 (at %), Metals, 2021, vol. 11, p. 1145. https://doi.org/10.3390/met11071145

Prokofyev, E., Gunderov, D., Prokoshkin, S., and Valiev, R., Microstructure, Mechanical and Functional Properties of NiTi Alloys Processed by ECAP Technique, ESOMAT, 2009, p. 06028. https://doi.org/10.1051/esomat/200906028

Lídia, F., Lucas, C., Guido, V., Andrea, K., Heide, K., Bernardi, H., and Otubo, J., ECAE Processed NiTi Shape Memory Alloy, Mater. Res., 2014, vol. 17, pp. 186–190. https://doi.org/10.1590/S1516-14392014005000034

Churakova, A., Yudahina, A., Kayumova, E., and Tolstov, N., Mechanical Behavior and Fractographic Analysis of a TiNi Alloy with Various Thermomechanical Treatment, MATEC Web. Conf., 2019, vol. 298, p. 00019. https://doi.org/10.1051/matecconf/201929800019

Lotkov, A.I., Grishkov, V.N., Baturin, A.A., Dudarev, E.F., Zhapova, D.Yu., and Timkin, V.N., The Effect of Warm Deformation by abc-Pressing Method on Mechanical Properties of Titanium Nickelide, Lett. Mater., 2015, vol. 5, pp. 170–174. https://doi.org/10.22226/2410-3535-2015-2-170-174

Lotkov, A., Grishkov, V., Zhapova, D., Timkin, V., Baturin, A., and Kashin, O., Superelasticity and Shape Memory Effect after Warm abc-Pressing of TiNi-Based Alloy, Mater. Today Proc., 2017, vol. 4, pp. 4814–4818. https://doi.org/10.1016/j.matpr.2017.04.076

Kashin, O., Krukovskii, K., Lotkov, A., and Grishkov, V., Effect of True Strains in Isothermal abc Pressing on Mechanical Properties of Ti49.8Ni50.2 Alloy, Metals, 2020, vol. 10(10), p. 1313. https://doi.org/10.3390/met10101313

Gubicza, J., Balogh, L., Hellmig, R.J., Estrin, Y., and Ungár, T., Dislocation Structure and Crystallite Size in Severely Deformed Copper by X-Ray Peak Profile Analysis, Mater. Sci. Eng. A, 2005, vol. 400–401, pp. 334–338. https://doi.org/10.1016/j.msea.2005.03.042

Starink, M.J., Qiao, X.G., Zhang, J., and Gao, N., Predicting Grain Refinement by Cold Severe Plastic Deformation in Alloys Using Volume Averaged Dislocation Generation, Acta Mater., 2009, vol. 57, pp. 5796–5811. https://doi.org/10.1016/j.actamat.2009.08.006

Qiao, X.G., Starink, M.J., and Gao, N., Hardness Inhomogeneity and Local Strengthening Mechanisms of an Al1050 Aluminum Alloy after One Pass of Equal Channel Angular Pressing, Mater. Sci. Eng. A, 2009, vol. 513–514, pp. 52–58. https://doi.org/10.1016/j.msea.2009.01.051

Chen, Y., Gao, N., Sha, G., Ringer, S.P., and Starink, M.J., Microstructural Evolution, Strengthening and Thermal Stability of an Ultrafine-Grained Al-Cu-Mg Alloy, Acta Mater., 2016, vol. 109, pp. 202–212. https://doi.org/10.1016/j.actamat.2016.02.050

Tatyanin, E.V., Kurdyumov, V.G., and Fedorov, V.B., Production of Amorphous Ti-Ni Alloys by High-Pressure Torsion, Fiz. Met. Metalloved., 1986, vol. 62, no. 1, pp. 133–137.

Koike, J., Parkins, D.M., and Nastasi, M., Crystal-to-Amorphous Transformation of NiTi Induced by Cold Rolling, J. Mater. Res., 1990, vol. 5, pp. 1414–1418. https://doi.org/10.1557/jmr.1990.1414

Churakova, A. and Gunderov, D.V., Microstructural and Mechanical Stability of a Ti–50.8 at % Ni Shape Memory Alloy Achieved by Thermal Cycling with a Large Number of Cycles, Metals, 2020, vol. 10, p. 227. https://doi.org/10.3390/met10020227

Lotkov, A., Grishkov, V., Laptev, R., Mironov, Y., Zhapova, D., Girsova, N., Gusarenko, A., Barmina, E., and Kashina, O., Crystal Structure Defects in Titanium Nickelide after abc Pressing at Lowered Temperature, Materials, 2022, vol. 15, p. 4298. https://doi.org/10.3390/ma15124298

Lin, H., Hua, P., Huang, K., Li, Q., and Sun, Q., Grain Boundary and Dislocation Strengthening of Nanocrystalline NiTi for Stable Elastocaloric Cooling, Scripta Mater., 2023, vol. 226, p. 115227. https://doi.org/10.1016/j.scriptamat.2022.115227

Liu, T., Wu, Z., Zhou, W., Zhong, M., Lin, J., and Yang, Y., Quasilinear Pseudoelasticity and Small Hysteresis in SLM-Fabricated NiTi, J. Alloys Compd, 2023, vol. 933, p. 167694. https://doi.org/10.1016/j.jallcom.2022.167694

Shi, X.B., Guo, F.M., Zhang, J.S., Ding, H.L., and Cui, L.S., Grain Size Effect on Stress Hysteresis of Nanocrystalline NiTi Alloys, J. Alloys Compd, 2016, vol. 688, pp. 62–68. https://doi.org/10.1016/j.jallcom.2016.07.168

Warren, B.E. and Averbach, B.L., The Separation of Cold-Work Distortion and Particle Size Broadening in X-Ray Patterns, J. Appl. Phys., 1952, vol. 23, p. 497. https://doi.org/10.1063/1.1702234

Williamson, G.K. and Hall, W.H., X-Ray Line Broadening from Filed Aluminium and Wolfram, Acta Metall., 1953, vol. 1, pp. 22–31. https://doi.org/10.1016/0001-6160(53)90006-6

Krill, C.E. and Birringer, R., Estimating Grain-Size Distributions in Nanocrystalline Materials from X-Ray Diffraction Profile Analysis, Philos. Mag. A, 1998, vol. 77, pp. 621–640. https://doi.org/10.1080/01418619808224072

Williamson, G.K. and Smallman, R.E., Dislocation Densities in Some Annealed and Cold-Worked Metals from Measurements on the X-Ray Debye–Scherrer Spectrum, Philos. Mag., 1956, vol. 1, pp. 34–46. https://doi.org/10.1080/14786435608238074

Smallman, R.E. and Westmacott, K.H., Stacking Faults in Face-Centered Cubic Metals and Alloys, Philos. Mag., 1957, vol. 2, pp. 669–683. https://doi.org/10.1080/14786435708242709

Chumlyakov, Yu.I., Surikova, N.S., and Korotaev, A.D., Orientation Dependence of Strength and Plastic Properties of Titanium Nickelide Single Crystals, Fiz. Met. Metalloved., 1996, vol. 81, no. 6, pp. 148–158.

Surikova, N.S. and Chumlyakov, Yu.I., The Peculiarities of Deformation and Fracture of Hardened Titanium Nickelide, Phys. Mesomech., 2000, vol. 3, no. 1, pp. 93.

Pelton, A.R., Russell, S.M., and DiCello, J., The Physical Metallurgy of Nitinol for Medical Applications, JOM, 2003, vol. 55, pp. 33–37. https://doi.org/10.1007/s11837-003-0243-3

Elahinia, M.H., Hashemi, M., Tabesh, M., and Bhaduri, S.B., Manufacturing and Processing of NiTi Implants: A Review, Progr. Mater. Sci., 2012, vol. 57, pp. 911–946. https://doi.org/10.1016/j.pmatsci.2011.11.001

Lin, H.C. and Wu, S.K., Determination of Heat of Transformation in a Cold Rolled Martensitic TiNi Alloy, Metall. Trans. A, 1993, vol. 24, pp. 293–299. https://doi.org/10.1007/BF02657316

Mahmud, A.S., Wu, Z., Yang, H., and Liu, Y., Effect of Cold Work and Partial Annealing on Thermomechanical Behaviour of Ti–50.5 at % Ni, Shape Memory Superelasticity, 2017, vol. 3, pp. 57–66. https://doi.org/10.1007/s40830-017-0103-6

Lotkov, A.I., Grishkov, V.N., Udovenko, V.A., and Kuznetsov, A.V., Effect of Low-Temperature Annealing on the Martensite Start Temperature in Titanium Nickelide, Fiz. Met. Metalloved., 1982, vol. 54, no. 6, pp. 1202–1204.

Baturin, A.A. and Lotkov, A.I., Determination of Vacancy Formation Energy of TiNi Compounds with a B2 Structure by Positron Annihilation, Fiz. Met. Metalloved., 1993, vol. 76, no. 2, pp. 168–170.

Funding

The investigation was carried out within the government statement of work for ISPMS SB RAS (research line FWRW-2021-0004).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors of this work declare that they have no conflicts of interest.

Additional information

Publisher's Note. Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mironov, Y.P., Lotkov, A.I., Grishkov, V.N. et al. Changes in the Structural-Phase State and Dislocation Density of Ti49.8Ni50.2 Alloy Depending on the Isochronal Annealing Temperature after Severe Plastic Deformation by abc Pressing at 573 K. Phys Mesomech 27, 175–182 (2024). https://doi.org/10.1134/S1029959924020061

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1029959924020061