Abstract

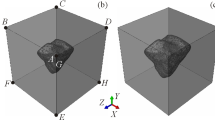

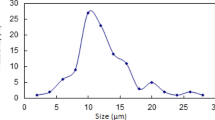

This work studies the formation and evolution of residual stresses in metal matrix composites with different volume fractions and sizes of reinforcement particles. The investigation was performed on hot-pressed samples of pure aluminum with boron and titanium carbide particles. The samples were subjected to mechanical compression tests to study their fracture behavior. Residual stresses were measured after cooling, as well as at different degrees of deformation of the composites. Some samples were subjected to electron beam processing. The phase composition and size of boron carbide particles in their recast surface layers, which were formed by recrystallization from the liquid phase during irradiation, were examined by X-ray diffraction. The cooling process followed by mechanical loading of the composites was simulated by simultaneously taking into account the fracture of the matrix and particles. The formation of residual stresses in composites with different particle volume fractions was numerically investigated.

Similar content being viewed by others

REFERENCES

Physical Mesomechanics of Heterogeneous Media and Computer-Aided Design of Materials, Panin, V.E., Ed., Cambridge: Cambridge International Science Publishing, 1998.

Multiscale Materials Modeling: Approaches to Full Multiscaling, Schmauder, S. and Schäfer, I., Eds., Berlin: De Gruyter, 2016.

Romanova, V.A., Soppa, E., Schmauder, S., and Balokhonov, R.R., Mesomechanical Analysis of the Elasto-Plastic Behavior of a 3D Composite-Structure under Tension, Comput. Mech., 2005, vol. 36, pp. 475–483.

Balokhonov, R.R., Romanova, V.A., Schmauder, S., and Emelianova, E.S., A Numerical Study of Plastic Strain Localization and Fracture Across Multiple Spatial Scales in Materials with Metal-Matrix Composite Coatings, Theor. Appl. Fract. Mech., 2019, vol. 101, pp. 342–355.

Moiseenko, D.D., Maksimov, P.V., Panin, S.V., Schmauder, S., Panin, V.E., Babich, D.S., Berto, F., Vinogradov, A.Yu., and Brückner-Foit, A., Recrystallization at Crack Surfaces as a Specific Fracture Mechanism at Elevated Temperatures—Cellular Automata Simulation, Phys. Mesomech., 2020, vol. 23, no. 1, pp. 1–12. https://doi.org/10.1134/S1029959920010014

Balokhonov, R.R., Evtushenko, E.P., Romanova, V.A., Schwab, E.A., Bakeev, R.A., Emelyanova, E.S., Zinovyeva, O.S., Zinovyev, A.V., and Sergeev, M.V., Formation of Bulk Tensile Regions in Metal Matrix Composites and Coatings under Uniaxial and Multiaxial Compression, Phys. Mesomech., 2020, vol. 23, no. 2, pp. 135–146. https://doi.org/10.1134/S1029959920020058

Muvvala, G., Karmakar, D.P., and Nath, A.K., In-Process Detection of Microstructural Changes in Laser Cladding of In-Situ Inconel 718/TiC Metal Matrix Composite Coating, J. Alloys Compd., 2018, vol. 740, pp. 545–558.

Tao, Y.-F., Li, J., Lv, Y.-H., and Hu, L.-F., Effect of Heat Treatment on Residual Stress and Wear Behaviors of the TiNi/Ti2Ni Based Laser Cladding Composite Coatings, Opt. Laser Tech., 2017, vol. 97, pp. 379–389.

Liu, D., Hu, P., and Min, G., Interfacial Reaction in Cast WC Particulate Reinforced Titanium Metal Matrix Composites Coating Produced by Laser Processing, Opt. Laser Tech., 2015, vol. 69, pp. 180–186.

Riquelme, A., Escalera-Rodríguez, M.D., Rodrigo, P., Otero, E., and Rams, J., Effect of Alloy Elements Added on Microstructure and Hardening of Al/SiC Laser Clad Coatings, J. Alloys Compd., 2017, vol. 727, pp. 671–682.

Verdi, D., Garrido, M.A., Múnez, C.J., and Poza, P., Influence of Exposure at High Temperature on the Local Scratch Mechanisms in Laser Cladded Inconel 625-Base Metal Matrix Composite Coatings, J. Alloys Compd., 2018, vol. 733, pp. 69–81.

Peat, T., Galloway, A., Toumpis, A., McNutt, P., and Iqbal, N., The Erosion Performance of Particle Reinforced Metal Matrix Composite Coatings Produced by Co-Deposition Cold Gas Dynamic Spraying, Appl. Surf. Sci., 2017, vol. 396, pp. 1623–1634.

Lee, Y.T.R., Ashrafizadeh, H., Fisher, G., and McDonald, A., Effect of Type of Reinforcing Particles on the Deposition Efficiency and Wear Resistance of Low-Pressure Cold-Sprayed Metal Matrix Composite Coatings, Surf. Coat. Tech., 2017, vol. 324, pp. 190–200.

Wang, W., Zengb, X., Lia, Y., Wang, D., Liu, Y., Yamaguchi, T., Nishio, K., and Cao, J., Fabrication, Microstructure, and Wear Performance of WC-Fe Composite/Metal Coating Fabricated by Resistance Seam Welding, Appl. Surf. Sci., 2018, vol. 439, pp. 468–474.

Cabezas-Villa, J.L., Olmos, L., Vergara-Hernández, H.J., Jiménez, O., Garnica, P., Bouvard, D., and Flores, M., Constrained Sintering and Wear Properties of Cu−WC Composite Coatings, Trans. Nonferr. Met. Soc. China, 2017, vol. 27, pp. 2214−2224.

Pramanik, Basak, A.K., Fracture and Fatigue Life of Al-Based MMCs Machined at Different Conditions, Eng. Fract. Mech., 2018, vol. 191, pp. 33–45.

Asif Iqbal, A.K.M., Chen, S., Arai, Y., and Araki, W., Study on Stress Evolution in SiC Particles during Crack Propagation in Cast Hybrid Metal Matrix Composites Using Raman Spectroscopy, Eng. Failure Analysis, 2015, vol. 52, pp. 109–115.

Josyula, S.K. and Narala, S.K.R., Study of TiC Particle Distribution in Al-MMCs Using Finite Element Modeling, Int. J. Mech. Sci., 2018, vol. 141, pp. 341–358.

Wang, D., Shanthraj, P., Springer, H., and Raabe, D., Particle-Induced Damage in Fe–TiB2 High Stiffness Metal Matrix Composite Steels, Mater. Design, 2018, vol. 160, pp. 557–571.

Shakoor, M., Bernacki, M., and Bouchard, P.-O., Ductile Fracture of a Metal Matrix Composite Studied Using 3D Numerical Modeling of Void Nucleation and Coalescence, Eng. Fract. Mech., 2018, vol. 189, pp. 110–132.

Jarząbek, D.M., Dziekoński, C., Dera, W., Chrzanowska, J., and Wojciechowski, T., Influence of Cu Coating of SiC Particles on Mechanical Properties of Ni/SiC Co-Electrodeposited Composites, Ceramics Int., 2018, vol. 44, pp. 21750–21758.

Ma, L., Huang, Ch., Dolman, K., Tang, X., Yang, J., Shi, Zh., and Liu, Zh.-Sh., A Method to Calculate the Bulk Hardness of Metal Matrix Composite Using Hadfield Steel Reinforced with Niobium Carbide Particles as an Example, Mech. Mater., 2017, vol. 112, pp. 154–162.

Zhang, J.F., Zhang, X.X., Wang, Q.Z., Xiao, B.L., and Ma, Z.Y., Simulations of Deformation and Damage Processes of SiCp/Al Composites during Tension, J. Mater. Sci. Tech., 2018, vol. 34, pp. 627–634.

Li, Y., Cao, J., and Williams, C., Competing Failure Mechanisms in Metal Matrix Composites and Their Effects on Fracture Toughness, Materialia, 2019. https://doi.org/10.1016/j.mtla.2019.100238

Balokhonov, R., Romanova, V., Schwab, E., Zemlianov, A., and Evtushenko, E., Computational Microstructure-Based Analysis of Residual Stress Evolution in Metal-Matrix Composite Materials during Thermomechanical Loading, Facta Univ. Mech. Eng., 2021. https://doi.org/10.22190/FUME201228011B

Funding

The work was supported by the Russian Science Foundation, Grant No. 18-19-00273, https://rscf.ru/en/project/18-19-00273/. Fracture model (3) used in this study was developed as part of the government statement of work for ISPMS SB RAS, Research Topic No. FWRW-2021-0002.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizicheskaya Mezomekhanika, 2021, Vol. 24, No. 5, pp. 5–15.

This paper is dedicated to Prof. Siegfried Schmauder who initiated and supported a long-term scientific and cultural collaboration between Tomsk and Stuttgart research teams

Rights and permissions

About this article

Cite this article

Balokhonov, R.R., Kulkov, A.S., Zemlyanov, A.V. et al. Evolution of Residual Stresses and Fracture in Thermomechanically Loaded Particle-Reinforced Metal Matrix Composites. Phys Mesomech 24, 503–512 (2021). https://doi.org/10.1134/S1029959921050015

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1029959921050015