Abstract

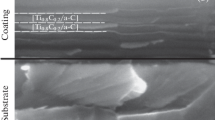

The wear resistance of diamond-like a-C:H coatings deposited onto substrates of R6M5 steel through intermediate Ti-C layers with a titanium concentration of 10 to 90% is studied. The a-C:H coatings with a thickness of 1500 nm are fabricated via the destruction of acetylene in the plasma of a non-self-maintained discharge generated by an electron beam in a mixture of acetylene and argon. Intermediate Ti–C layers with a thickness of ~100 nm are fabricated by the arc sputtering of a titanium alloy (VT-1-0) cathode in the acetylene-argon plasma of a non-self-maintained discharge. The partial pressure of argon is kept constant (0.03 Pa), and that of acetylene varied from 0.01 to 1 Pa. An increase in the acetylene pressure is accompanied by a decrease in the titanium concentration in Ti–C. Testing the coatings in a jet of silicon-carbide particles with an average size of 100 microns, incident normally to the surface at a speed of 10 m/s, shows that the composition and structure of the intermediate layers have a significant effect on the stability of a-C:H coatings. An increase in the carbon content in the Ti–C structure leads to a decrease in the size of crystal inclusions in the amorphous matrix, increasing the probability of the formation of interphase boundaries that inhibit the movement and generation of dislocations (the source of crack origin), the advance of which destroys the hard coating. Amorphous carbon in Ti–C provides good interlayer adhesion. During the deposition of a-C:H on Ti–C, there is a cohesive bonding between the same phases (carbon) and adhesive bonding between different phases (carbon and titanium carbide).

Similar content being viewed by others

REFERENCES

D. Martínez-Martínez, C. López-Cartes, A. Fernández, and J. C. Sánchez-López, Thin Solid Films 517, 1662 (2009).

A. P. Rubshtein, A. B. Vladimirov, and S. A. Plotnikov, Solid State Phenom. 279, 153 (2018).

T. Vitu, T. Polcar, and L. Cvrcek, Surf. Coat. Technol. 202, 5790 (2008).

Y. Wang, X. Zhang, and X. Wu, Mater. Sci. Eng., A 488, 112 (2008).

I. Sh. Trakhtenberg, N. V. Gavrilov, S. A. Plotnikov, A. B. Vladimirov, A. P. Volkova, and E. G. Rubshtein, Phys. Met. Metallogr. 115, 771 (2014).

I. Sh. Trakhtenberg, A. B. Vladimirov, A. P. Rubstein, V. A. Yugov, V. B. Vykhodets, T. E. Kurennykh, A. G. Gontar, V. N. Tkach, and S. N. Dub, Superhard Mater. 29, 138 (2007).

N. V. Gavrilov and A. I. Men’shakov, Instrum. Exp. Tech. 54, 732 (2011).

D. R. Emlin, S. A. Plotnikov, and N. V. Gavrilov, Izv. Vyssh. Uchebn. Zaved., Fiz. 55, 66(2012).

A. P. Rubshtein, K. Gao, A. B. Vladimirov, S. A. Plotnikov, B. Zhang, and J. Zhang, Surf. Coat. Technol. 377, 124912 (2019).

A. P. Rubshtein, A. B. Vladimirov, Y. V. Korkh, Y. S. Ponosov, and S. A. Plotnikov, Surf. Coat. Technol. 309, 680 (2017).

A. B. Vladimirov, S. A. Plotnikov, I. Sh. Trakhtenberg, A. P. Rubshtein, and E. G. Volkova, Prot. Met. Phys. Chem. Surf. 51, 230 (2015).

A. P. Rubshtein, A. B. Vladimirov, and S. A. Plotnikov, Phys. Met. Metallogr. 121, 1203 (2020).

Funding

The study was carried out within the framework of the state assignment of the Ministry of Education and Science of Russia (topic “Function”, No. AAAA-A19-119012990095-0), with partial support from the Russian Foundation for Basic Research (project no. 20-48-660065).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Plotnikov, S.A., Rubshtein, A.P. & Vladimirov, A.B. On the Wear Resistance of Diamond-Like Carbon Coatings Deposited onto Ti–C Layers of Varying Composition. J. Surf. Investig. 15 (Suppl 1), S126–S130 (2021). https://doi.org/10.1134/S1027451022020331

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1027451022020331