Abstract

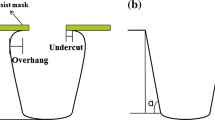

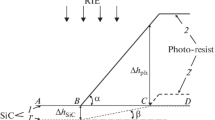

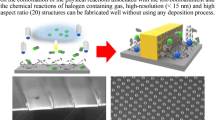

A method to form tapered structures via the cyclic plasma-chemical etching of silicon using a spherical photoresist mask is described. The method is based on the possibility of controlling the structure profile by adjusting the silicon and photoresist etching selectivity. In this study, to control the selectivity value, each cycle of the well-known two-stage Bosch silicon etching process is supplemented with a third stage, namely, photoresist etching in oxygen-containing plasma. A model of transformation of the photoresist-mask contour during etching is developed using the experimental results. The parameters of the additional stage are calculated for each silicon etching cycle in terms of model concepts. The result is the formation of tapered structures with a sidewall taper angle close to the target value.

Similar content being viewed by others

REFERENCES

S.-E. Cheon, H.-S. Lee, J. Choi, A. R. Jeong, T. S. Lee, D. S. Jeong, K.-S. Lee, W.-S. Lee, W. M. Kim, H. Lee, and I. Kim, Sci. Rep. 7, 7336 (2017). https://doi.org/10.1038/s41598-017-07463-7

A. A. Talin, D. Ruzmetov, A. Kolmakov, K. McKelvey, N. Ware, F. E. Gabaly, B. Dunn, H. and S. White, ACS Appl. Mater. Interfaces 8, 32385 (2016). https://doi.org/10.1021/acsami.6b12244

R. Li, Y. Lamy, W. F. Besling, F. Roozeboom, and P. M. Sarro, J. Micromech. Microeng. 18, 125023 (2008). https://doi.org/10.1088/0960-1317/18/12/125023

F. Saffih, C. Con, A. Alshammari, M. Yavuz, and B. Cui, J. Vac. Sci. Technol., B: Nanotechnol. Microelectron.: Mater., Process., Meas., Phenom. 32, 06FI04 (2014). https://doi.org/10.1116/1.4901420

R. F. Figueroa, S. Spiesshoefer, S. L. Burkett, and L. Schaper, J. Vac. Sci. Technol., B: Microelectron. Nanometer Struct.—Process., Meas., Phenom. 23, 2226 (2005). https://doi.org/10.1116/1.2041654

P. Dixit, S. Vähänen, J. Salonen, and P. Monnoyer, ECS J. Solid State Sci. Technol. 1, 107 (2012). https://doi.org/10.1149/2.022203jss

M. Rattner and S. D. Chinn, US Patent No. 6 849 554 (2005).

N. Roxhed, P. Griss, and G. Stemme, J. Micromech. Microeng. 17, 1087 (2007). https://doi.org/10.1088/0960-1317/17/5/031

M. G. De Boer, J. G. E. Gardeniers, H. V. Jansen, E. Smulders, M. Gilde, G. Roelofs, J. N. Sasserath, and M. Elwenspoek, J. Microelectromech. Syst. 11, 385 (2002). https://doi.org/10.1109/JMEMS.2002.800928

C. M. Waits, B. Morgan, M. Kastantin, and R. Ghodssi, Sens. Actuators, B 119, 245 (2005). https://doi.org/10.1016/j.sna.2004.03.024

R. Nagarajan, US Patent Application US20020166838A1 (2002).

F. T. O’Neill and J. T. Sheridan, Optik 113, 391 (2002). https://doi.org/10.1078/0030-4026-00186

P. Nussbaumyx, R. Völkely, H. P. Herzigy, M. Eisnerz, and S. Haselbeckz, Pure Appl. Opt. 6, 617 (1997). https://doi.org/10.1088/0963-9659/6/6/004

ACKNOWLEDGMENTS

This work was performed using equipment of the Center for collective use “Diagnostics of Microstructures and Nanostructures.”

Funding

This work was supported by the Ministry of Education and Science of the Russian Federation under a state task to Demidov Yaroslavl State University (no. 0856-2020-0006).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by M. Timoshinina

Rights and permissions

About this article

Cite this article

Rudy, A.S., Morozov, O.V. & Kurbatov, S.V. A Modernized Bosch Etching Process for the Formation of Tapered Structures on a Silicon Surface. J. Surf. Investig. 15, 461–466 (2021). https://doi.org/10.1134/S1027451021030162

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1027451021030162