Abstract

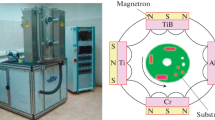

An analysis of methods for the formation of amorphous and crystal-amorphous materials and coatings is presented. The factors that influence the formation of an amorphous structure in materials are studied. The coatings made by cathodic-arc deposition with two single-component titanium and aluminum cathodes are deposited onto high-speed steel samples. Using X-ray diffraction analysis, the influence of the location of the sample in the vacuum chamber relative to the center on the degree of crystallinity of the coating structure is determined. Investigations of the influence of the speed of rotation of the working table about the axis on the percentage of the amorphous phase in the intermetallic coatings are performed. It is discovered that the highest content of the amorphous component is observed in the samples farthest from the axis of the table. This is due to the fact that the samples are under conditions of relatively rapid cooling. Based on the research results, a coating technology based on intermetallic compounds of the system (Ti,Al)N with an amorphous-crystalline structure made by cathodic-arc deposition with two single-component cathodes is developed.

Similar content being viewed by others

REFERENCES

D. Loktev and E. Yamashkin, Nanoindustriya, No. 4, 18 (2007).

S. N. Grigor’ev, Methods of Increasing the Resistance of Cutting Tools: A Textbook for University Students (Mashinostroenie, Moscow 2009) [in Russian].

H. Kou, J. Lu, and Y. Li, Adv. Mater. 26, 5518 (2014). https://doi.org/10.1002/adma.201401595

M. V. Nozhenkov, J. Surf. Invest.: X-Ray, Synchrotron Neutron Tech. 9, 518 (2015).

K. Asami, et al., Corros. Sci. 16, 909 (1976). https://doi.org/10.1016/S0010-938X(76)80010-8

V. I. Betekhtin, A. G. Kadomtsev, and O. V. Tolochko, Phys. Solid State 43, 1892 (2001).

V. I. Zel’dovich, N. Yu. Frolova, V. P. Pilyugin, V. M. Gundyrev, and A. M. Patselov, Phys. Met. Metallogr. 99, 425 (2005).

V. K. Balla and A. Bandyopadhyay, Surf. Coat. Technol. 205, 2661 (2010). https://doi.org/10.1016/j.surfcoat.2010.10.029

S. N. Grigor’ev, V. P. Tabakov, and M. A. Volosova, Technological Methods for Increasing the Wear Resistance of Cutting Tool Contact Areas (TNT, Staryi Oskol, 2011).

Ya. L. Gurevich, Modes of Cutting Hard Materials: Handbook (Mashinostroenie, Moscow, 1986) [in Russian]

E. L. Vardanyan, Candidate’s Dissertation in Technical Sciences (Moscow, 2015).

S. R. Shekhtman, Doctoral Dissertation in Technical Sciences (Moscow, 2015).

Yu. I. Averko-Antonovich and R. T. Bikmullin, Methods for Studying the Structure and Properties of Polymers (Kazan. Gos. Tekh. Univ., Kazan’, 2002) [in Russian].

Yu. A. Lebedev, Yu. M. Korolev, V. M. Polikarpov, L. N. Ignat’eva, and E. M. Antipov, Crystallogr. Rep. 55, 609 (2010).

G. E. Abrosimova, A. S. Aronin, and N. N. Kholstinina, Phys. Solid State 52, 445 (2010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Maslov, A.A., Nagimov, R.S., Nazarov, A.U. et al. Technology of the Deposition of Ti–Al–N Amorphous-Crystalline Coatings. J. Surf. Investig. 15, 85–88 (2021). https://doi.org/10.1134/S1027451020060117

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1027451020060117