Abstract

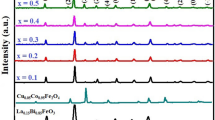

The effect of mechanical activation on the structure and conductivity of the KNO3–Al2O3 composite is considered. The analysis of DSC curves measured in the course of heating of the 0.5KNO3–0.5Al2O3 composite shows that the enthalpy of phase transitions decreases with the increase in the time of mechanical activation. Based on the X-ray diffraction analysis, it is shown that the mechanical activation reduces the grain size and makes the grains more defective. According to the data of electrochemical impedance spectroscopy, the ionic conductivity of the system KNO3–Al2O3 obtained by mechanical activation is 3.8 × 10–5 S/cm at T = 373 К and 2 × 10–3 S/cm at T = 473 К and its activation energy is 0.19 eV, which is comparable with the parameters of composites with the same chemical composition obtained by the ceramic method. The Raman spectroscopic study reveals the formation of the metastable γ-KNO3 phase in the system KNO3–Al2O3 at the temperature above 397 К. The increase in conductivity of the KNO3–Al2O3 composite at 373–403 К is associated with the presence of an additional metastable γ-KNO3 phase.

Similar content being viewed by others

REFERENCES

Aziam, H., Larhrib, B., Hakim, Ch., Sabi, Youcefa, H.B., and Saadounec, I., Solid-state electrolytes for beyond lithium-ion batteries: A review, Renewable Sustainable Energy Rev., 2022, vol. 167, p. 112694. https://doi.org/10.1016/j.rser.2022.112694

Gafurov, M.M. and Rabadanov, K.Sh., High-temperature vibrational spectroscopy of molten electrolytes, Appl. Spectrosc. Rev., 2022, vol. 57, p. 2048305. https://doi.org/10.1080/05704928.2022.2048305

Hu, Q., Sun, Zh., Nie, L., Chen Sh., Yu, J., and Liu, W., High-safety composite solid electrolyte based on inorganic matrix for solid-state lithium-metal batteries, Mater. Today Energy, 2022, vol. 27, p. 101052. https://doi.org/10.1016/j.mtener.2022.101052

Dirican, M., Yan, C., Zhu, P., and Zhang, X., Composite solid electrolytes for all-solid-state lithium batteries, Mater. Sci. Eng., R, 2019, vol. 136, p. 27. https://doi.org/10.1016/j.mser.2018.10.004

Liu, J., Zhang, D., Xu, X., Qin, Y., Ji, S., Huo, Y., Wang, Zh., Liu, Zh., and Shen, J., Recent progress of organic-inorganic composite solid electrolytes for all-solid-state lithium batteries, Chem. – Eur. J., 2019, vol. 26(8), p. 04461. https://doi.org/10.1002/chem.201904461

Uvarov, N.F., Ulihin, A.S., and Mateyshina, Yu.G., Nanocomposite alkali-ion solid electrolytes, Adv. Nanomater. Catal. Energy, 2022, p. 393–434. https://doi.org/10.1039/D2CP01837C

Cheng, Z., Liu, T., Zhao, B., Shen, F., Jin, H., and Han, X., (2020). Recent advances in organic-inorganic composite solid electrolytes for all-solid-state lithium batteries, Energy Storage Mater., 2021, vol. 34, p.388. https://doi.org/10.1016/j.ensm.2020.09.016

Ulikhin, A.S., Novozhilov, D.V., Khusnutdinov, V.R., Sinelnikova, Yu.E., and Uvarov, N.F., Ionic conductivity of LiTi2(PO4)3–LiClO4 composites, Russ. J. Electrochem., 2022, vol. 58, p. 580. https://doi.org/10.1134/S102319352207014X

Chen, A., Qu, C., Shi, Y., and Shi, F., Manufacturing strategies for solid electrolyte in batteries, Front. Energy Res., 2020, vol. 8. p. 571440. https://doi.org/110.3389/fenrg.2020.571440

Famprikis, T., Canepa, P., Dawson, J.A., Saiful, Islam M., and Masquelier, Ch., Fundamentals of inorganic solid-state electrolytes for batteries, Nat. Mater., 2019, vol. 18, p. 1278. https://doi.org/10.1038/s41563-019-0431-3

Yang, R., Cui, L., and Zheng, Y., The synthesis of composite particles in molten salts, Mater. Trans., 2006, vol. 47(3), p. 584. https://doi.org/10.2320/matertrans.47.584

Gupta, S.K. and Mao, Y., A review on molten salt synthesis of metal oxide nanomaterials: Status, opportunity, and challenge, and challenge, Prog. Mater. Sci., 2021, vol. 117, p. 100734. https://doi.org/10.1016/j.pmatsci.2020.100734

Liu, X., Fechler, N., and Antonietti, M., Salt melt synthesis of ceramics, semiconductors and carbon nanostructures, Chem. Soc. Rev., 2013, vol. 42(21), p. 8237. https://doi.org/10.1039/c3cs60159e

Gonzalo-Juan, I. and Riedel, R., Ceramic synthesis from condensed phases, ChemTexts, 2016, vol. 2, p. 6. https://doi.org/10.1007/s40828-016-0024-6

Lee, W., Lyon, C.K., Seo, J., Lopez-Hallman, R., Leng, Y., Wang, C.-Y., Hickner, M.A., Randall, C.A., and Gomez, E.D., Ceramic–salt composite electrolytes from cold sintering, Adv. Funct. Mater., 2019, p. 1807872. https://doi.org/10.1002/adfm.201807872

Leonardi, M., Villacampa, M., and Menéndez, J.C., Multicomponent mechanochemical synthesis, Chem. Sci., 2018, vol. 9(8), p. 2042. https://doi.org/10.1039/c7sc05370c

Uvarov, N.F., Composite solid electrolytes: recent advances and design strategies, J. Solid State Electrochem., 2011, vol. 15(2), p. 367. https://doi.org/10.1007/s10008-008-0739-4

Nimmo, J.K. and Lucas, B.W., A neutron diffraction determination of the crystal structure of γ-phase potassium nitrate at 25°C and 100°C, J. Phys. C: Solid State Phys., 1973, vol. 6, p. 201. https://doi.org/10.1088/0022-3719/6/2/001

Nimmo, J.K. and Lucas, B.W., The crystal structures of γ- and β-KNO3 and the α-γ-β phase transformations, Acta Crystallogr., Sect. B, 1976, vol. B32, p. 1968. https://doi.org/10.1107/S0567740876006894

Poprawski, R., Rysiakiewicz-Pasek, E., Sieradzki, A., Man, A., and Polanska, J., Ferroelectric phase transitions in KNO3 embedded into porous glasses, J. Non-Cryst. Solids, 2007, vol. 353(47-51), p. 4457. https://doi.org/10.1016/j.jnoncrysol.2007.01.086

Ataev, M.B., Gafurov, M.M., Emirov, R.M., Rabada-nov, K.Sh., and Amirov, A.M., Phase composition and the structure of (1 – x)KNO3 + xAl2O3 nanocomposites by X-ray diffraction, Phys. Solid State, 2016, vol. 58(12), p. 2423.] https://doi.org/10.1134/S1063783416120027

Wolf, S., Alam, N., and Feldmann, C., δ-KNO3: Synthesis and structure of a new modification of potassium nitrate, Z. Anorg. Allg. Chem., 2015641(2), p. 383. https://doi.org/10.1002/zaac.201400538

Baryshnikov, S.V., Charnaya, E.V., Milinskiy, A.Y., Stukova, E.V., Tien, Ch., Böhlmann, W., and Michel, D., Dielectric properties of mixed NaNO2–KNO3 ferroelectrics in nanoporous silicate matrices, Phys. Solid State, 2009, no. 6(51), p. 1172.] https://doi.org/10.1134/S1063783409060262

Sieradzki, A., Komar, J., Rysiakiewicz-Pasek, E., Ciżman, A., and Poprawski, R., Calorimetric investigations of phase transitions in KNO3 embedded into porous glasses, Ferroelectrics, 2010, vol. 402, p. 60. https://doi.org/10.1080/00150191003697393

Naberezhnov, A.A., Vanina, P.Y., Sysoeva, A.A., Ciźman, A., Rysiakiewicz-Pasek, E, and Hoser, A., Effect of restricted geometry on the structure and phase transitions in potassium nitrate nanoparticles, Phys. Solid State, 2018, no. 3(60), p. 442. https://doi.org/10.1134/S1063783418030204

Baryshnikov, S.V., Charnaya, E.V., Milinskiy, A.Y., and Patrushev, Y.V., Phase transitions in KNO3 embedded in MCM-41 films with regular nanopores, Phys. Solid State, 2013, no. 12(55), p. 2566.

Milinskii, A.Yu., Baryshnikov, S.V., Stukova, E.V., Charnaya, E.V., Chernechkin, I.A., and Uskova, N.I., Dielectric and thermal properties of KNO3 encapsulated in carbon nanotubes, Phys. Solid State, 2021, no. 6(63), p. 872. https://doi.org/10.1134/S1063783421060147

Lia, X., Zhao, R., Fu, Y., and Manthiramb, A., Nitrate additives for lithium batteries: Mechanisms, applications, and prospects, eScience, 2021, vol. 1(2), p. 108. https://doi.org/10.1016/j.esci.2021.12.006

Jia, W., et al., Extremely accessible potassium nitrate (KNO3) as the highly efficient electrolyte additive in lithium battery, ACS Appl. Mater. Interfaces, 2016, vol. 8(24), p. 15399. https://doi.org/10.1021/acsami.6b03897

Hosaka, T., Kubota, K., Kojima, H., and Komaba, S., Highly concentrated electrolyte solutions for 4 V class potassium-ion batteries, Chem. Commun., 2018, vol. 54(60), p. 8387. https://doi.org/10.1039/c8cc04433c

Zhang, X., Meng, J., Wang, X., Xiao, Z., Wu, P., and Mai, L., Comprehensive insights into electrolytes and solid electrolyte interfaces in potassium-ion batteries, Energy Storage Mater., 2021, vol. 38, p. 30. https://doi.org/10.1016/j.ensm.2021.02.036

Uvarov, N.F., Hairetdinov, E.F., and Skobelev, I.V., Composite solid electrolytes MeNO3–Al2O3 (Me = Li, Na, K), Solid State Ionics, 1996, vol. 86–88, p. 577. https://doi.org/10.1016/0167-2738(96)00208-1

Amirov, A.M., Gafurov, M.M., and Rabadanov, K.Sh., Analysis of the KNO3–Al2O3 system by differential scanning calorimetry, Phys. Solid State, 2016, vol. 58(9), p. 1930.https://doi.org/10.1134/S1063783416090067

Amirov, A.M., Suleymanov, S.I., Gafurov, M.M., et al., Study of the MNO3–Al2O3 nanocomposites by differential scanning calorimetry, J. Therm. Anal. Calorim., 2022. https://doi.org/10.1007/s10973-022-11256-0

Gafurov, M.M., Rabadanov, K.S., Ataev, M.B., Amirov, A.M., Akhmedov, M.A., Shabanov, N.S., Kubataev, Z.Y., and Rabadanova, D.I., Research of the structure and dynamic interactions of particles in the Li0.42K0.58NO3 – R (R = α-Al2O3, γ-Al2O3, SiO2) and (LiNO3–LiClO4) – γ-Al2O3 composites in various temperature conditions and phase states, Spectrochim. Acta, Part A, 2021, vol. 257, p. 119765. https://doi.org/10.1016/j.saa.2021.119765

Raju, A., Vennela, A., Mallaiah, Y., Sathish, M., Reddy, S.N., and Sadanandachary, A., Ionic conductivity studies of KNO3:KCl solid composite electrolyte system, Int. J. Eng. Res. Ind. Appl., 2020, vol. 10(12), p. 48. https://doi.org/10.9790/9622-1012024852

Rabadanov, K.Sh., Gafurov, M.M., Kubataev, Z.Y., Amirov, A.M., Akhmedov, M.A., Shabanov, N.S., and Ataev, M.B., Ion conductivity and vibrational spectra of LiNO3–KNO3 + Al2O3 composites, Russ. J. Electrochem., 2019, vol. 55, p. 573. https://doi.org/10.1134/S1023193519060168

Nakamoto, K., Infrared and Raman Spectra of Inorganic and Coordination Compounds, Chichester: Wiley-Interscience, 1986.

Murugan, R., Huang, P.J., Ghule, A., and Chang, H., Studies on thermal hysteresis of KNO3 by thermo-Raman spectroscopy, Thermochim. Acta, 2000, vol. 346, p. 83. https://doi.org/10.1016/S0040-6031(99)00364-0

ACKNOWLEDGMENTS

The study was carried out using the instruments of the Analytical Center of Collective Use of the Dagestan Federal Research Center of the Russian Academy of Sciences.

Funding

This study was financially supported by the Foundation for Assistance to Innovations (grant no. 4470GS1/72582 from February 15, 2022 (С1-112576)).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by T. Safonova

Based on the materials of the 16th International Meeting “Fundamental Problems of Solid State Ionics”, Chernogolovka, June 27–July 3, 2022.

Rights and permissions

About this article

Cite this article

Akhmedov, M.A., Gafurov, M.M., Rabadanov, R.S. et al. The Effect of Mechanical Activation on the Conductivity in the System KNO3‒Al2O3. Russ J Electrochem 59, 589–597 (2023). https://doi.org/10.1134/S1023193523080037

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1023193523080037