Abstract

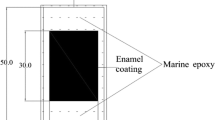

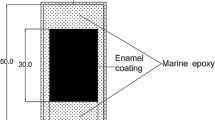

The corrosion behavior of enamel coating on carbon steel was investigated in the tap water at 80°C (i.e., the simulated electric hot water tank environments) by using scanning electron microscopy (SEM), energy dispersive X-ray spectroscopy (EDS) and electrochemical measurement techniques. The through porosity of enamel coating is about 0.0076%, simply measured by in-situ electrochemical impedance spectroscopy (EIS) in the dilute sulfuric acid solution. The through defects facilitate the solution penetration in the coating and the formation of occluded corrosion cell on the steel substrate in the hot tap water. The occluded zones have low resistances to both ionic transport and active corrosion. The steady steel corrosion is controlled by the oxygen diffusion via the enamel coating defects, which is accompanied by the transport of anion ions and corrosion products.

Similar content being viewed by others

REFERENCES

Rossi, S., Parziani, N., and Zanella, C., Abrasion resistance of vitreous enamel coatings in function of frit composition and particles presence, Wear, 2015, vols. 332–333, p. 702.

Barcova, K., Mashlan, M., and Zboril, R., Phase composition of steel-enamel interfaces: effects of chemical pre-treatment, Surf. Coat. Technol., 2006, vol. 201, p. 1836.

Mezinskis, G., Pavlovska, I., and Malnieks, K., Sol–gel coated enamel for steel: 250 days of continuous high-temperature stability, Ceram. Int., 2017, vol. 43, p. 2974.

Lins, V.D.F.C., Reis, G.F.D.A., and Araujo, C.R.D., Electrochemical impedance spectroscopy and linear polarization applied to evaluation of porosity of phosphate conversion coatings on electrogalvanized steels, Appl. Surf. Sci., 2006, vol. 253, p. 2875.

Tang, F.J., Cheng, X.M., and Chen, G.D., Electrochemical behavior of enamel-coated carbon steel in simulated concrete pore water solution with various chloride concentrations, Electrochim. Acta, 2013, vol. 92, p. 36.

Tang, F.J., Chen, G.D., and Volz, J.S., Cement-modified enamel coating for enhanced corrosion resistance of steel reinforcing bars, Cement Concr. Compos., 2013, vol. 35, p. 171.

Tang, F.J., Chen, G.D., and Volz, J.S., Microstructure and corrosion resistance of enamel coatings applied to smooth reinforcing steel, Construt. Build. Mater., 2012, vol. 35, p. 376.

Tang, F.J., Chen, G.D., and Brow, R.K., Corrosion resistance and mechanism of steel rebar coated with three types of enamel, Corros. Sci., 2012, vol. 59, p. 157.

Tang, F.J., Bao, Y., and Chen, Y.Z., Impact and corrosion resistances of duplex epoxy/enamel coated plates, Construct. Build. Mater., 2016, vol. 112, p. 7.

Tang, F.J., Chen, G.D., and Brow, R.K., Chloride-induced corrosion mechanism and rate of enamel-and epoxy-coated deformed steel bars embedded in mortar, Cement Concr. Res., 2016, vol. 82, p. 58.

Liu, J., Zhang, L.W., and Mu, X.L., Studies of electrochemical corrosion of low alloy steel under epoxy coating exposed to natural seawater using the WBE and EIS techniques, Prog. Org. Coat., 2017, vol. 111, p. 315.

Li, M.C., Luo, S.Z., and Wu, P.F., Photocathodic protection effect of TiO2 films for carbon steel in 3% NaCl solutions, Electrochim. Acta, 2005, vol. 50, p. 3401.

Sabouri, M., Shahrabi, T., and Hosseini, M.G., Improving corrosion protection performance of polypyrrole coating by tungstate ion dopants, Russ. J. Electrochem., 2007, vol. 43, p. 1390.

Levi, M.D., Gofer, Y., and Aurbach, D., Effect of the structure of nonuniform conducting polymer films on their electrochemical impedance response, Russ. J. Electrochem., 2004, vol. 40, p. 273.

Panić, V.V., Dekanski, A.B., and Milonjić, S.K., Electrocatalytic activity of sol–gel-prepared RuO2/Ti anode in chlorine and oxygen evolution reactions, Russ. J. Electrochem., 2006, vol. 42, p. 1055.

Creus, J., Mazille, H., and Idrissi, H., Porosity evaluation of protective coatings onto steel, through electrochemical techniques, Surf. Coat. Technol., 2000, vol. 130, p. 224.

Sarin, P., Snoeyink, V.L., and Bebee, J., Iron release from corroded iron pipes in drinking water distribution systems: effect of dissolved oxygen, Water Res., 2004, vol. 38, p. 1259.

Baek, W.C., Kang, T., and Sohn, H.J., In situ surface enhanced Raman spectroscopic study on the effect of dissolved oxygen on the corrosion film on low carbon steel in 0.01 M NaCl solution, Electrochim. Acta, 2001, vol. 46, p. 2321.

Li, M.C., Royer, M., and Stien, D., Inhibitive effect of sodium eperuate on zinc corrosion in alkaline solutions, Corros. Sci., 2008, vol. 50, p. 1975.

Song, G.L. and Shi, Z., Corrosion mechanism and evaluation of anodized magnesium alloys, Corros. Sci., 2014, vol. 85, p. 126.

Cui, L.Y., Fang, X.H., and Cao, W., In vitro corrosion resistance of a layer-by-layer assembled DNA coating on magnesium alloy, Appl. Surf. Sci., 2018, vol. 457, p. 49.

Ahn, S.H., Lee, J.H., and Kim, H.G., A study on the quantitative determination of through-coating porosity in PVD-grown coatings, Appl. Surf. Sci., 2004, vol. 233, p. 105.

Liu, C., Bi, Q., and Leyland, A., An electrochemical impedance spectroscopy study of the corrosion behaviour of PVD coated steels in 0.5 N NaCl aqueous solution: part II.: EIS interpretation of corrosion behaviour, Corros. Sci., 2003, vol. 45, p. 1257.

Zeng, A., Liu, E., and Annergren, I.F., EIS capacitance diagnosis of nanoporosity effect on the corrosion protection of DLC films, Diam. Relat. Mater., 2002, vol. 11, p. 160.

Xin, Y., Jiang, J., and Huo, K., Corrosion resistance and cytocompatibility of biodegradable surgical magnesium alloy coated with hydrogenated amorphous silicon, J. Biomed. Mater. Res. A, 2009, vol. 89, p. 717.

Yang, X., Jha, A., and Brydson, R., An analysis of the microstructure and interfacial chemistry of steel-enamel interface, Thin Solid Films, 2003, vol. 443, p. 33.

Zucchelli, A., Dignatici, M., and Montorsi, M., Characterization of vitreous enamel–steel interface by using hot stage ESEM and nano-indentation techniques, J. Eur. Ceram. Soc., 2012, vol. 32, p. 2243.

Samiee, L., Sarpoolaky, H., and Mirhabibi, A., Microstructure and adherence of cobalt containing and cobalt free enamels to low carbon steel, Mater. Sci. Eng. A, 2007, vol. 458, p. 88.

Barcova, K., Mashlan, M., and Zboril, R., Phase composition of steel-enamel interfaces: effects of chemical pre-treatment, Surf. Coat. Technol., 2006, vol. 201, p. 1836.

Mansfeld, F., Use of electrochemical impedance spectroscopy for the study of corrosion protection by polymer coatings, J. Appl. Electrochem., 1995, vol. 25, p. 187.

Cui, L.Y., Zeng, R.C., and Guan, S.K., Degradation mechanism of micro-arc oxidation coatings on biodegradable Mg–Ca alloys: the influence of porosity, J. Alloys Compd., 2017, vol. 695, p. 2464.

Zhang, S.D., Wu, J., and Qi, W.B., Effect of porosity defects on the long-term corrosion behaviour of Fe-based amorphous alloy coated mild steel, Corros. Sci., 2016, vol. 110, p. 57.

Mouanga, M., Puiggali, M., and Devos, O., EIS and LEIS investigation of aging low carbon steel with Zn–Ni coating, Electrochim. Acta, 2013, vol. 106, p. 82.

Park, J.H., Lee, G.D., Ooshige, H., Nishikata, A., and Tsuru, T., Monitoring of water uptake in organiccoatings under cyclic wet-dry condition, Corros. Sci., 2003, vol. 45, p. 1881.

Zhou, C.L., Lu, X., and Xin, Z., Polybenzoxazine/SiO2 nanocomposite coatings for corrosion protection of mild steel, Corros. Sci., 2014, vol. 80, p. 269.

Xue, F., Wei, X., and Dong, J.H., Effect of residual dissolved oxygen on the corrosion behavior of low carbon steel in 0.1 M NaHCO3 solution, J. Mater. Sci. Technol., 2018, vol. 34, p. 1349.

Wang, S.R., Du, C.W., and Li, X.G., Field corrosion characterization of soil corrosion of X70 pipeline steel in a red clay soil, Prog. Nat. Sci. Mater. Int., 2015, vol. 25, p. 242.

Kuznetsov, Y.I., Vershok, D.B., and Timashev, S.F., Features of formation of magnetite coatings on low-carbon steel in hot nitrate solutions, Russ. J. Electrochem., 2010, vol. 46, p. 1155.

Funding

The authors greatly appreciate the financial support provided by National Natural Science Foundation of China (grant no. U1960103 and U1660205).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Ronghai Xu, Xin, S., Ni, Q. et al. Initial Corrosion Characteristics of Enamel Coated Carbon Steel in Hot Tap Water. Russ J Electrochem 57, 636–643 (2021). https://doi.org/10.1134/S1023193520120265

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1023193520120265