Abstract

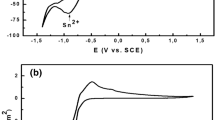

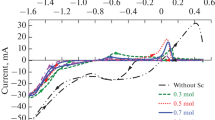

A technique for obtaining binary Cu-Sn alloys containing 20–35 mol % Sn is proposed. The technique—the electrochemical deposition out of silicofluoride electrolytes—ensures a high deposition rate of coatings (25–50 μm h−1). The formation of intermetallic compound Cu10Sn3 is found to occur at a high current density, in conditions of the tin reduction depolarization and the copper reduction superpolarization. The alloys consist of submicron grains. Apart from crystalline Cu10Sn3, they include x-ray-amorphous tin (2–12 mol %) and tin oxides (≤1–3 mol %). The alloys feature high hardness (4200 MPa), corrosion resistance, and solderability.

Similar content being viewed by others

References

Povetkin, V.K., Kovenskii, I.M., and Ustinovshchikov, Yu.M., Struktura i svoistva elektroliticheskikh splavov (electrolytic Alloys: Structure and Properties), Moscow: Nauka, 1992.

Gamburg, Yu.D., Elektrokhimicheskaya kristallizatsiya metallov i splavov (The Electrocrystallization of Metals and Alloys), Moscow: Yanus-K, 1997.

Mel’nikov, P.S., Spravochnik po gal’vanopokrytiyam v mashinostroenii (Electrocoatings in Machine Building: A Handbook), Moscow: Mashinostroenie, 1991.

Burkhardt, W., Galvanotechnic., 1993, vol. 84, p. 2585.

Ryaboi, A.I., Khovrin, E.V., and Vashentseva, S.M., Gal’vanotekh. Obrab. Poverkhn., 1993, vol. 2, p. 52.

Odinokova, I.V., Kosmodamianskaya, L.V., and Tyutina, K.M., Gal’vanotekh. Obrab. Poverkhn., 2002, vol. 10, p. 23.

Vorobyova, T.N. and Reva, O.V., Sb. rabot, posv. 100-letiyu N.F. Ermolenko (A Collection of Papers Devoted to N.F. Ermolenko’s Centennial), Minsk: Belsens, 2000, p. 196.

Reva, O.V., Vorobyova, T.N., and Sviridov, V.V., Elektrokhimiya, 1999, vol. 35, p. 1070.

Vorobyova, T.N., Bobrovskaya, V.P., and Sviridov, V.V., Met. Finish., 1997, vol. 95, p. 14.

Vorobyova, T.N., Bobrovskaya, V.P., and Reva, O.V., Gal’vanotekh. Obrab. Poverkhn., 1997, vol. 5, p. 26.

Dudnik, V.V., Kolloidn. Zh., 1998, vol. 60, p. 107.

Salem, R.R., Poverkhnost, 1998, no. 4, p. 57.

Grillikhes, S.Ya. and Tikhonov, K.I., Elektrokhimicheskie i khimicheskie pokrytiya (Electrochemical and Chemical Coatings), Leningrad: Khimiya, 1990.

Spravochnik gal’vanotekhnika (Electroplater’s Handbook), Ginberg, A.M., Ed., Moscow: Metallurgiya, 1987.

Foppelius, T., Gal’vanotekh. Obrab. Poverkhn., 1993, vol. 2, p. 55.

Reva, O.V., Vorobyova, T.N., and Kuznetsov, B.V., Remont, Vosst., Moderniz, 2004, no. 1, p. 9.

Handbuch der Praeparativen anorganischen Chemie, Brauer, G., Ed., Stuttgart: Ferdinand Enke, 1975–1981, vol. 3.

Author information

Authors and Affiliations

Additional information

Original Russian Text © O.V. Reva, T.N. Vorobyova, B.V. Kuznetsov, 2006, published in Elektrokhiniya, 2006, Vol. 42, No. 1, pp. 44–51.

Rights and permissions

About this article

Cite this article

Reva, O.V., Vorobyova, T.N. & Kuznetsov, B.V. Alloying during codeposition of copper and tin out of silicofluoride electrolytes. Russ J Electrochem 42, 38–44 (2006). https://doi.org/10.1134/S1023193506010071

Received:

Issue Date:

DOI: https://doi.org/10.1134/S1023193506010071