Abstract

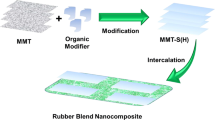

75/25 (wt %) NR/BR blend/clay nanocomposites were prepared via a combined latex/melt intercalation method, for the first time. At first, NR latex was mixed with various amounts of the aqueous sodium montmorillomte (Na-MMT) dispersion. Obtained mixtures were co-coagulated by dilute solution of the sulfuric acid, washed several times with the distilled water and dried under vacuum. The NR/ clay compounds were then mixed with given amounts of the BR and vulcanizing ingredients in a 6-inch two-roll mill and then vulcanized at 150°C in a hot press. The nanocomposites have better mechanical properties than the clay-free NR/BR blend vulcanizates. Furthermore, modulus and hardness (Shore A) increased by increase of the clay loading in the range of 0–15 phr while tensile strength and elongation at break increased with increasing the clay content up to 5 phr and then decreased gradually by further increase of the clay loading. It was concluded from results of the XRD and mechanical test that nanocomposites containing less than 10 phr clay may show the fully exfoliated structure. With increasing the clay content to 10 and 15 phr, both non-exfoliated (stacked layers) and exfoliated structures may be observed simultaneously in the nanocomposites. TGA results indicated an improvement in main and end decomposition by increasing the clay loading.

Similar content being viewed by others

References

J. S. Shelley, P. T. Mather, and K. L. DeVries, Polymer 42, 5849 (2001).

S. Joly, G. Garnaud, R. Ollirault, L. Bokobza, and J. E. Mark, Chem. Mater. 14, 4202 (2002).

G. R. Hamed, Rubber Chem. Technol. 73, 524 (2000).

J. Karger-Kocsis and C. M. Wu, Polym. Eng. Sci. 44, 1083 (2004).

M. Alexandre and P. Dubois, Mater. Sci. Eng. Rep. 28, 1 (2000).

P. Kodgire, R. Kalgaonkar, S. Hambir, N. Bulakh, and J. P. Jog, J. Appl. Polym. Sci. 812, 1786 (2001).

Q. X. Jia, Y. P. Wu, Y. L. Xu, H. H. Mao, and L. Q. Zhang, Macromol. Mater. Eng. 291, 218 (2006).

L. Liu, D. Jia, Y. Luo, and B. Guo, J. Appl. Polym. Sci. 100, 1905 (2006).

J. Ma, J. Xu, J. H. Ren, Z. Z. Yu, and Y. W. Mai, Polymer 44, 4619 (2003).

G. C. Psarras, K. G. Gatos, and J. Karger-Kocsis, J. Appl. Polym. Sci. 106, 1405 (2007).

S. Varghese, K. G. Gatos, A. A. Apostolov, and J. Karger-Kocsis, J. Appl. Polym. Sci. 922, 543 (2004).

S. Varghese and J. Karger-Kocsis, Polymer 44, 4921 (2003).

M. Abdollahi, A. Rahmatpour, J. Aalaie, and G. Khanbabae, Iran. Polym. J. 7, 519 (2008).

L. Q. Zhang, Y. Z. Wang, Y. Q. Wang, Y. Sui, and D. Yu, J. Appl. Polym. Sci. 78, 1873 (2000).

Y. Z. Wang, L. Q. Zhang, C. Tang, and D. Yu, J. Appl. Polym. Sci. 78, 1879 (2000).

J. Ma, P. Xiang, Y. W. Mai, and L. Q. Zhang, Macromol. Rapid Commun. 25, 1692 (2004).

Y. Q. Wang, H. Zhang, Y. Wu, J. Yang, and L. Q. Zhang, J. Appl. Polym. Sci. 96, 324 (2005).

M. Abdollahi, A. Rahmatpour, J. Aalaie, and H. H. Khanli, e-Polymers, No. 074 (2007).

A. Rahmatpour, M. Abdollahi, and M. Shojaee, J. Macromol. Sci., Phys. 47, 523 (2008).

M. Mehrabi Kooshki and A. Jalali Arani, e-Polymers, No. 132 (2009).

Y. P. Wu, L. Q. Zhang, Y. Q. Wang, Y. Liang, and D. S. Yu, J. Appl. Polym. Sci. 82, 2842 (2001).

Y. Wang, H. Zhang, Y. Wu, J. Yang, and L. Zhang, Eur. Polym. J. 41, 2776 (2005).

M. Abdollahi, A. Rahmatpour, and H. H. Khanli, e-Polymers, No. 151 (2007).

H. Qin, S. Zhang, C. Zhao, M. Feng, M. Yang, Z. Shu, and S. Yang, Polym. Degrad. Stab. 85, 807 (2004).

Y. Xu, W. J. Brittain, R. A. Vaia, and G. Price, Polymer 47, 4564 (2006).

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Abdollahi, M., Khanli, H.H., Aalaie, J. et al. Structure and properties of natural rubber/butadiene rubber (NR/BR) blend/sodium-montmorillonite nanocomposites prepared via a combined latex/melt intercalation method. Polym. Sci. Ser. A 53, 1175–1181 (2011). https://doi.org/10.1134/S0965545X11120091

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0965545X11120091