Abstract

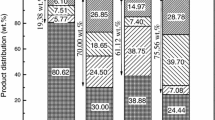

The distribution of vanadium and nickel upon hydroconversion of vacuum tower bottoms in the presence of slurried MoS2, Ni7S6, (NH4)0.25 ⋅ WO3, and Fe1 − xS nanoparticles has been studied. The experiments have been performed in an autoclave reactor and in a flow-through hydroconversion unit. It has been shown that the coke yield in hydrocracking reactions increases in the order MoS2, Ni7S6, (NH4)0.25 ⋅ WO3, Fe1 − xS. The proportion of metals in the toluene-insoluble hydroconversion residue increases in the same order. As the hydroconversion temperature increases, the transfer of vanadium and nickel to condensation products increases. According to electron microscopy data for the toluene insolubles, it can be assumed that vanadium and nickel are bonded to carbon, enter into the coke composition, and do not form compounds with the active phase of the MoS2 catalyst.

Similar content being viewed by others

REFERENCES

N. O. Kapustin and D. A. Grushevenko, Rev. IFP Energ. Nouv. 73 (67), 1 (2018). https://doi.org/10.2516/ogst/2018063

S. A. Shaban, H. S. Ahmed, M. F. Menoufy, and Y. Fathy, Egypt. J. Pet. 22, 367 (2013). https://doi.org/10.1016/j.ejpe.2013.10.006

J. Ancheyta, Deactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and Modeling (John Wiley, Hoboken, NJ, 2016).

S. K. Maity, V. H. Pérez, J. Ancheyta, and M. S. Rana, Energy Fuels 21, 636 (2007). https://doi.org/10.1021/ef060495z

S. N. Khadzhiev, Kh. M. Kadiev, and M. Kh. Kadieva, Pet. Chem. 54, 323 (2014). https://doi.org/10.1134/S0965544114050065

G. Bellussi, G. Rispoli, A. Landoni, et al., J. Catal. 308, 189 (2013). https://doi.org/10.1016/j.jcat.2013.07.002

T. N. Manh and T. N. Ngoc, J. Ind. Eng. Chem. 43, 1 (2016). https://doi.org/10.1021/ef700253f

M. J. Angeles, C. Leyva, J. Ancheyta, and S. Ramírez, Catal. Today 5, 274 (2014). https://doi.org/10.1016/j.cattod.2013.08.016

S. N. Khadzhiev, Pet. Chem. 56, 465 (2016). https://doi.org/10.1134/S0965544116060050

G. Bellussi, G. Rispoli, D. Molinari, et al, Catal. Sci. Technol., No. 3, 176 (2013). https://doi.org/10.1039/c2cy20448g

Kh. M. Kadiev, S. N. Khadzhiev, M. Kh. Kadieva, and E. S. Dogova, Pet. Chem. 57, 608 (2017). https://doi.org/10.1134/S0965544117070039

S. Zhang, D. Liu, W. Deng, and G. Que, Energy Fuels 21, 3057 (2007). https://doi.org/10.1021/ef700253f

G. P. Dechaine and M. R. Gray, Energy Fuels 24, 2795 (2010). https://doi.org/10.1021/ef100173j

J. Chirinos, D. Oropeza, J. González, et al., Energy Fuels 27, 2431 (2013). https://doi.org/10.1021/ef3020052

I. T. Caga, I. D. Carnell, and J. M. Winterbottom, J. Chem. Technol. Biotechnol. 76, 179 (2001). https://doi.org/10.1016/S0926-860X(00)00587-1

R. A. Ware and J. Wei, J. Catal. 93, 100 (1985). https://doi.org/10.1016/0021-9517(85)90155-1

R. A. Ware and J. Wei, J. Catal. 93, 135. https://doi.org/10.1016/0021-9517(85)90157-5

C. H. Philip, M. Carlos, and E. Scott, Polyhedron 5, 237 (1986). https://doi.org/10.1016/S0277-5387(00)84916-5

H. Liu, S. Fan, Z. Wang, et al., Chem. Select. 2, 16 139 (2017). https://doi.org/10.1002/slct.201601936

A. L. Maksimov, L. A. Zekel’, M. Kh. Kadieva, et al., Pet. Chem. 59, 968 (2019).

Kh. M. Kadiev, N. V. Oknina, A. L. Maksimov, et al., Res. J. Pharm. Biol. Chem. Sci. 7, 704 (2016).

S. N. Khadzhiev, Kh. M. Kadiev, L. A. Zekel’, and M. Kh. Kadieva, Pet. Chem. 58, 535. https://doi.org/10.1134/S0965544118070046

Funding

This work was carried out as part of the state assignment of the Topchiev Institute of Petrochemical Synthesis, Russian Academy of Sciences.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare no conflict of interest requiring disclosure in this article.

Additional information

Translated by S. Zatonsky

Rights and permissions

About this article

Cite this article

Kadiev, K.M., Zekel’, L.A., Kadieva, M.K. et al. Behavior of Vanadium and Nickel in Hydroconversion of Vacuum Tower Bottoms over Nanosized Slurry Catalysts. Pet. Chem. 60, 1009–1018 (2020). https://doi.org/10.1134/S0965544120090133

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0965544120090133