Abstract

In this research, a process is discussed for upgrading reformate and power former in Iraq’s Al-Doura refinery, by reducing the amount of benzene in the gasoline product with simultaneous reduction in the gasoline’s ASTM distillation end point. The process consists of fractionation of the reformate and power former to recover that fraction (90–180°C) of hydrocarbons. This was directly used as gasoline without further conversion. The heavy bottom fraction (180°C—EBP) consisting of the aromatic and non-aromatic hydrocarbons was recovered and used as antiknock additives to gasoline. The other fraction with (IBP—90°C) was used as feedstock to producing benzene by solvent extraction. The reformate and power former fractions (90–180°C) are blended with light straight run naphtha at ratio (75: 25) to producing gasoline as well as Al Doura gasoline. It was found that the amount of benzene was reduced from 1.41 wt % in the original pool to 1.37 and 1.31 in the alternative products. Engine emissions were also reduced when using the alternative products compared with original pool product.

Similar content being viewed by others

Abbreviations

- ASTM:

-

American System Testing Method

- BTX:

-

Benzene Toluene Xylene

- EBP:

-

End Boiling Point

- FCC:

-

Fluid Catalytic Cracking

- HSRN:

-

Heavy Straight Run Naphtha

- IBP:

-

Initial Boiling Point

- LSRN:

-

Light Straight Run Naphtha

- RON:

-

Research Octane Number

- RVP:

-

Reid Vapor Pressure

- U.S. Pat.:

-

United State Patent

References

Tsuboi Katsumi, “Unleaded high octane gasoline composition,” United States Patent, 6187171 B1, 2001.

Al Doura Refinery, Light Oil Unit.

A. Eh. Eiman Sheet and Jehad Yamin, International Journal of Chemical Engineering Research 2(3), 269 (2010).

Proj. 1390, Seorgi Baghdad Doura Refinery New Refining Complex Catalytic Reforming Unit Operating Manuol.

N. Harandi Mohsen, “Process for production gasoline having lower benzene content and distillationend point,” US Patent no. 5347061, 1994.

Ed. by M. Imbriani, S. Ghittori, G. Pezzagno, and E. Capodaglio, “Update on benzene,” in Advances in Occupational Medicine and Rehabilitation, Vol. 2 (PI-ME Press, Pavia, Italy, 1995).

American Petroleum Institute (API): Analysis of Foods for Benzene, Ed. by W. P. Rose (Departmental Report Number DR 16) (National Food Laboratory/Health and Environmental Sciences Department, Washington D.C., 1992).

World Health Organization (WHO): Environmental Criteria 150: Benzene. Geneva: International Programme on Chemical Safety (IPCS), WHO/United Nations Environment Programme/International Labour Organisation, 1993.

CONCAWE, CEFIC Aromatics Producers Association and EUROPIA: Benzene Risk Characterization (96TP 57), (Exxon Biomedical Services, East Millstone, N.J., 1996).

R. R. Jacobs and W. Phanprasit, Am. Ind. Hyg. Assoc. J. 54, 569 (1993).

H. Tsurutu, Ind. Health 20, 335 (1982).

American Petroleum Institute (API): Absorption of Petroleum Products Across the Skin of Monkey and Man, Ed. by T. J. Franz (API Med. Res. Pub. 32-32749) (American Petroleum Institute/Health and Environmental Sciences Department, Washington, D.C., 1984).

I. H. Blank and D. J. McAuliffe, J. Invest. Dermatol. 85, 522 (1985).

R. D. Edwards and M. J. Jantunen, Atmospheric Environment 35, 1411 (2001).

P. R. D. Williams, J. M. Panko, K. Unice, J. L. Brown, and D. J. Paustenbach, Journal of Occupational and Environmental Hygiene 5, 565 (2008).

D. K. Verma and K. des Tombe, AIHA Journal 63, 225 (2002).

G. C. Sinclair, R. C. Wester, and H. I. Maibach, Deakin University, P.O. Box 210, Glen Iris, Victoria 3146, Australia, AIHA Journal 63(6), 685–688.

D. K. Verma, D. M. Johnson, M. L. Shaw, and K. des Tombe, AIHAJ 62, 176 (2001).

M. A. Quddus, S. Ahmed, and S. N. Sarwar, Petroleum Science and Technology 25, 829 (2007).

Swee-Cheng Foo, “Benzene pollution from gasoline usage,” Science of The Total Environment 103(1), 19 (1991).

A. B. Lindstrom, V. R. Highsmith, T. J. Buckley, W. J. Pate, and L. C. Michael, J. Exposure Analysis and Environmental Epidemiology 4(2), 183 (1994).

R. E. Palmer, S. H. Kao, C. Tong, and D. R. Shipman, Hydrocarbon Processing, 2008, p. 55.

S. Chanvaivit, P. Navasumrit, P. Hunsonti, H. Autrup, and M. Ruchirawat, Mutat Res. 626(1–2), 79 (2006).

S. J. W. Adriaan and R. J. Lawson, “Process for reducing benzene content in gasoline,” US Patent no. 5120890, 1992.

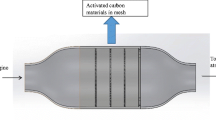

S. G. C. Laredo, M. J. J. Castillo, P. F. Hernandez, M. C. R. Saint, G. M. C. del Martinez, C. F. J. Jimenez, R. O. de la Marroquin, and D. J. L. Cano, “Process for reducing benzene content of hydrocarbon stream using microporous carbon adsorbent,” US Patent no. 8354019, 2013.

A. A. Chin, N. A. Collins, M. N. Harandi, R. T. Thomson, and R. A. Ware, “Benzene reduction in gasoline by alkylation with higher olefins,” US Patent no. 5491270, 1996.

M. N. Harandi, H. Owen, and P. H. Schipper, “Process for producing gasoline having lower benzene content and distillation end point,” US Patent no. 5347061, 1994.

J.-C. Collin, B. Juguin, J. Larue, and A. Rojey, “Method of reducing the benzene content of gasolines,” US Patent no. 5185486, 1993.

J. W. A. Sachtler and R. J. Lawson, “Process for reducing benzene content in gasoline,” US Patent no. 5120890, 1992.

W. A. Groten and K. L. Rock, “Process for the production of low benzene gasoline,” US Patent no. 7175754, 2007.

E. A. Eh. Sheet, International Journal of Applied Engineering Research, ISSN 0973-4562 5(11), 1905 (2010).

IROX 2000 Portable Gasoline Analysis.

E. A. Eh. Sheet and J. Yamin, Arabian Journal for Science and Engineering (Springer, 2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Sheet, E.A.E., Alawi, N.M. Process for producing high octane gasoline having lower benzene content and distillation end point with its environmental effect of engine exhaust emissions. Pet. Chem. 54, 157–164 (2014). https://doi.org/10.1134/S0965544114020091

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0965544114020091