Abstract

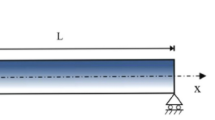

The heat-induced variations in material properties for a layered glass-metal composite material were studied for the case of induction heating and the subsequent composite annealing of the sample. A cylindrical sample of the composite (outer metal cylinder covering the glass cylinder) was used in our experimental study. This sample is an imitation of a brittle rock under a high stress. The simulation complexity originates from superposition of the glass point transition within the glass layer, induction heating for the whole sample, and heat radiation from the external metallic surface. Structural and mechanical relaxation processes in glass are calculated using the Boltzmann-Volterra superposition and the Tula-Narayanaswami-Mazurin-Moynihan (TNMM) model based on introducing a structural temperature as an additional parameter. The paper offers a mathematical model and a simulation method for calculating the temperature field and material properties distributions during the composite production process. The simulation results are presented for various regimes of heating and for glass-metal composite properties. This approach is useful for evaluating the operation modes of the glass layer annealing and for estimating the evolution of laminated composite materials.

Similar content being viewed by others

References

V.V. Pikul, Efficiency of glass-metal composites, Perspektivnye Materialy, 2000, No. 6, P. 63–65.

L.S. Zimin and A.V. Baikin, Using of inductive heating in industrial technologies, State of art and perspectives in electric technologies, in: Proc. Scientific Conf. (XVII Beradanos’ Lections). Vo. 1, Ivanovo, 2013, P. 3–7.

O.V. Mazurin, Annealing for Glass-to-metal Seal, Energia, Leningrad, 1980.

O.V. Mazurin, Glass Transition, Nauka, Leningrad, 1986.

S.V. Nemilov, Optical Material Science: Thermodynamic and Relaxation Properties of Glass-Producing Melts and Glasses, St.Peterburg: SPSU ITMO, 2014.

Yu.K. Startsev, Relaxation Phenomena in Glasses for Vitrification While Annealing, Glass-Salt Melt Ion Exchange and in Seals; Ph.D diss, 01.04.07. St. Petersburg, 2001.

T.V. Tropin, J.W.P. Schmelzer, and V.L. Aksenov, Modern aspects of the kinetic theory of glass transition, Physics-Uspekhi, 2016, Vol. 186, No. 1, P. 42–68.

C.T. Moynihan, P.B. Macedo, C.J. Montrose, P.K. Gupta, M.A. DeBolt et al. Structural relaxation in vitreous material, Ann. N. Y. Acad. Sci., 1976, Vol. 279, P. 15–35.

O.S. Narayanaswami, A model of structural relaxation in glass, J. Amer. Ceram. Soc., 1971, Vol. 54, No. 10, P. 491–498.

J.W.P. Schmelzer, Kinetic criteria of glass formation and the pressure dependence of the glass transition temperature, The J. Chemical Phys., 2012, Vol. 136, No. 7, P. 074512–1-074512-11.

A.Q. Tool, Relation between inelastic deformability and thermal expansion of glass in its annealing range, J. Amer. Ceram. Soc., 1946, Vol. 29, No. 9, P. 240–253.

N.A. Rubtsov, To analysis of heating and melting processes in a layer of semitransparent material, Thermophysics and Aeromechanics, 2012, Vol. 19, No. 4, P. 629–640.

N.A. Rubtsov and S.D. Sleptsov, Radiant-conductive heat transfer in semitransparent medium with phase transition at boundaries with different absorptivity, Thermophysics and Aeromechanics, 2010, Vol. 17, No. 2, P. 221–228.

A.Yu. Krainov and L.L. Minkov, Numerical Methods for Solving Heat and Mass Transfer Problems; Student training material, STT, Tomsk, 2016.

S.A. Chernavskii and V.F. Reschikov, Metal Engineer Handbook, Vol. 1, 3rd edition, Mashinostroenie, Moscow, 1976.

O.N. Lyubimova and S.A. Dryuk, Simulation parameters of temperature in the process of manufacturing a glass-metal composite, Thermophysics and Aeromechanics, 2017, Vol. 24, No. 1, P. 127–135.

Author information

Authors and Affiliations

Corresponding author

Additional information

Research was supported by the Russian Foundation for Basic Research through the science project No. 19-33-90200.

Rights and permissions

About this article

Cite this article

Lyubimova, O.N., Barbotko, M.A. Modeling of heat transfer due to induction heating of laminated glass-metal materials. Thermophys. Aeromech. 28, 87–102 (2021). https://doi.org/10.1134/S0869864321010091

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0869864321010091