Abstract—

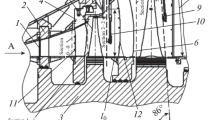

The need of traversing the flow gas-dynamic parameters, when trying out new last stages of a steam turbine’s low-pressure cylinders (LPC), is shown. The specific features of pressure measurements according to the pneumometric method by means of probes in the last stages operating in a wet steam (two-phase) medium, with the probe’s receiving holes and pneumatic lines becoming blocked with condensate, are shown. The changeover for using small-size probe heads featuring better measurement accuracy in comparison with large-size heads is substantiated. A universal algorithm for purging the pneumatic lines periodically with atmospheric air for various probes with receiving holes of certain diameters is proposed. The universal algorithm is obtained by supplementing the system with a subroutine that automatically monitors the time delay after closing the purging valves prior to carrying out measurements at the traversing point. At that, excluded are incomplete removal of residual purging air with condensate from the pneumatic lines and excessive time delay before measurements. The algorithm is implemented in improving the previously developed traversing system. Better accuracy of measuring the pressures and flow meridian angles is achieved owing to the use of high-precision transducers in each of the probe measurement channels with the absolute pressure range 0–30 kPa with the accuracy equal to 0.05% of the upper measurement limit. The time taken to process the traversing results is decreased by adding three measurement channels to the system, which operate synchronously with the probe and characterize the turbine operation mode. A modern system for traversing the flow in the gap between blade rings of the last stages has been developed. The results of this development are used in studying the advanced steam turbine LPC compartment on the full-scale test bench at JSC Power Machines.

Similar content being viewed by others

REFERENCES

A. V. Moskalenko, A. V. Aleksandrov, A. L. Nekrasov, S. A. Ivanov, A. G. Dolganov, N. V. Kravtsova, O. D. Gostev, D. O. Mokrinskii, and A. S. Laskin, “An automated flow traversing measurement system in the last stages of large-capacity steam turbines,” Therm. Eng. 66, 27–35 (2019). https://doi.org/10.1134/S0040601519010051

M. G. Deich and G. A. Filippov, Two-Phase Flows in the Elements of Thermal Engineering Equipment (Energoatomizdat, Moscow, 1987) [in Russian].

G. A. Filippov, E. V. Stekol’shchikov, and M. P. Anisimova, “Energy characteristics of wet steam flows and their measurement by pneumometric probes,” Tr. TsKTI, No. 65, 38−44 (1966).

N. N. Ermashov, “Combined nozzle with constant purge for measuring gas-dynamic parameters with a turbine operating on wet steam,” Tr. TsKTI, No. 80, 116−118 (1967).

B. N. Agafonov, V. N. Sadovnichii, N. P. Agafonova, V. I. Kirillov, and P. Yu. Prikhod’ko, “Combined probes for measuring flow parameters in interventional gaps of low-pressure cylinders,” Tyazh. Mashinostr., No. 3, 15−17 (1993).

A. L. Nekrasov, A. V. Moskalenko, V. K. Epifanov, and A. S. Laskin, “Improving schemes and methods for measuring flow parameters in the low pressure stages of a model steam turbine,” Nov. Ross. Elektroenerg., No. 11, 5−20 (2010).

E. Yu. Kolpishon, N. G. Razumov, Yu. A. Kirillov, A. A. Marchenko, M. V. Rodin, and V. M. Rekimchuk, “The use of additive technologies for the manufacture of products in mechanical engineering,” Tyazh. Mashinostr., No. 5−6, 30−36 (2022).

N. N. Afanas’eva, V. N. Busurin, I. G. Gogolev, R. I. D’yakonov, A. I. Kirillov, A. A. Klimtsov, K. L. Lapshin, A. S. Laskin, V. I. Popkov, and V. A. Chernikov, Aerodynamic Characteristics of Thermal Turbine Stages, Ed. by V. A. Chernikov (Mashinostroenie, Leningrad, 1980) [in Russian].

I. I. Kirillov and R. M. Yablonik, Fundamentals of Wet-Steam Turbine Theory (Mashinostroenie, Leningrad, 1968) [in Russian].

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by V. Filatov

Rights and permissions

About this article

Cite this article

Moskalenko, A.V., Tyukhtyaev, A.M., Kovalev, D.M. et al. Improving the Accuracy of Measurements of Gas-Dynamic Parameters in LPC Last Stages Using Modern Flow Traversing System in Studies on a Full-Scale Test Bench. Therm. Eng. 70, 388–396 (2023). https://doi.org/10.1134/S0040601523050038

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040601523050038