Abstract—

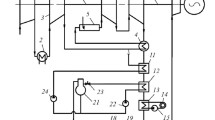

Heat recovery steam generators (HRSGs) are compared. HRSGs of gas turbines are designed for deep cooling of the exhaust gases while maximizing generation of steam at conditions corresponding to the working process of the steam turbine. To achieve this goal, the elements of the HRSG heating surface of the waste heat boiler are arranged so that the heated fluid (steam or water) is in the counterflow with exhaust gases from the gas turbine and heat transfer occurs in them at minimum temperature differences. Heat-exchange elements can be installed in both vertical and horizontal gas ducts. Accordingly, they are made from coils with horizontal pipes and inlet and outlet headers or from panels with vertical tubes, each with lower and upper headers. Panels in an element are connected with cross-over pipes to arrange a counterflow of the heated fluid (water or steam) and the gas turbine exhaust gases. This means that each bend of the coil of a vertical boiler is replaced with two headers connected with cross-over pipes in a horizontal boiler. The vertical arrangement of heat-transfer tubes in a horizontal gas requires the tubes of each panel to be properly drained using a branched drain system with shut-off valves and drain expansion tanks installed below the grade (el. 0). Heat-exchange elements made of horizontal tubes in the form of coils and located in a vertical gas duct are drained only through two headers, and the drainage expansion tank is installed at the grade (el. 0). The evaporating elements of a vertical HRSG are units with a parallel-flow pattern offering a uniform distribution of the steam generated in the evaporating coils, while the evaporative elements of a horizontal HRSG are cross-flow units featuring nonuniform distribution of the steam generated in the evaporating panels. An additional advantage of the vertical HRSG is provided by the stack effect increasing the power of the gas turbine. Despite the obvious heat-engineering advantages of vertical HRSGs, horizontal HRSGs are predominantly being built in Russia, although the global competition is observed between vertical and horizontal HRSGs, in which the customer’s opinion is decisive.

Similar content being viewed by others

REFERENCES

E. Jeffs, “Vertical HRSGs score or flexibility and reliability in later life,” Turbomach. Int., No. 3 (2003).

P. V. Roslyakov, K. A. Pleshanov, and K. V. Sterkhov, “A study of natural circulation in the evaporator of a horizontal-tube heat recovery steam generator,” Therm. Eng. 61, 465–472 (2014). https://doi.org/10.1134/S004060151407009X

K. V. Sterkhov, Study of Natural Circulation in a Vertical Recovery Boiler, Candidate’s Dissertation in Engineering (Moscow Power Engineering Inst., Moscow, 2017).

P. V. Roslyakov, K. A. Pleshanov, and K. V. Sterkhov, “Investigation of the operation of the circulation circuit with horizontal-type evaporator pipes by the example of the PK-79 recovery boiler of Chelyabinsk-1 combined heat and power plant,” in Proc. Int. Sci.-Tech. Conf. on Problems of Operation of Recovery Boilers of Steam–Gas Plants, Moscow, Apr. 26–27, 2018 (Vseross. Teplotekh. Inst., Moscow, 2018). https://vti.ru/ filemanager/download/1722

Vertical Natural Circulation HRSGs for Brighton Beach Power Station (2003). Artikel_brighton_beach_ve.doc.

I. I. Belyakov, V. I. Breus, A. B. Barannikov, L. A. Litvinova, and M. S. Popov, “Analysis of the reasons for the malfunction of the evaporation circuit of the recovery boiler of a 410 MW steam–gas unit,” Energetik, No. 5, 54–57 (2015).

Yu. P. Kurochkin, A. L. Shvarts, E. V. Somova, N. S. Galetskii, and O. B. Ott, “Direct-flow recovery boiler for a steam–gas unit,” RF Patent No. 89666 U1, Byull. Izobret., No. 34 (2009).

A. V. Moshkarin, B. L. Shelygin, and T. A. Zhamlikhanov, “Comparative analysis of vertical- and horizontal-type recovery boilers,” Vestn. IGEU, No. 4, 15–17 (2009).

A. V. Varvarskii, “Operation experience of the recovery boiler of the Nizhnevartovsk district power plant,” in Proc. Int. Sci.-Tech. Conf. on Problems of Operation of Recovery Boilers of Steam–Gas Plants, Moscow, Apr. 26–27, 2018 (Vseross. Teplotekh. Inst., Moscow, 2018). https://vti.ru/filemanager/download/1722

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by T. Krasnoshchekova

Rights and permissions

About this article

Cite this article

Berezinets, P.A., Tereshina, G.E. Heat Recovery Steam Generators of Binary Combined-Cycle Units. Therm. Eng. 68, 452–460 (2021). https://doi.org/10.1134/S0040601521060021

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040601521060021