Abstract

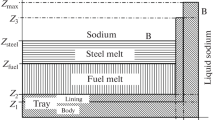

Based on the analysis of experiments carried out on simulators of fuel elements with a cladding of low-melting metals, models of melting and movement of the melt over the surface of fuel elements are proposed. The presented work is a continuation of experimental and theoretical work carried out jointly at the Nuclear Safety Institute, Russian Academy of Sciences, and Kutateladze Institute of Thermophysics, Siberian Branch, Russian Academy of Sciences, to study the features of the movement of a melt over a cylindrical surface that simulates the surface of a fuel element. It analyzes the factors that determine the thermal destruction of fuel elements. One of the important conclusions drawn from the analysis of experimental data was the conclusion about the prevailing film laminar runoff in the heated part of the fuel element simulator. Using this assumption, an analytical model was built that allows predicting the mass of a fuel element carried out of its limits during melting. As a result of calculations using the proposed model, it was shown that, for an accident with the introduction of positive reactivity, when the power increase can reach ten ratings, a modification of the model is necessary to take into account the turbulent runoff regime. For this purpose, a simplified model of the flow of the melt was built. A comparison is made with known techniques and it is shown that the proposed approach makes it possible to describe the turbulent flow regime with satisfactory accuracy. The modified model made it possible to calculate the features of the movement of a stainless steel melt over the surface of a fuel element of a fast neutron (BN) reactor. Information was obtained on the thickness of the melt, its velocity and Reynolds number, depending on the conditions of drainage, and on the mass carried outside the core.

Similar content being viewed by others

REFERENCES

P. D. Lobanov, E. V. Usov, A. I. Svetonosov, and S. I. Lezhnin, “Analysis of experimental data on melting and relocation of a metal melt on a cylindrical surface,” Thermophys. Aeromech. 27, 457–464 (2020).

P. D. Lobanov, E. V. Usov, V. S. Zhdanov, A. I. Svetonosov, and I. A. Klimonov, “Experimental and numerical determination of the rate of mass loss and temperature evolution of the single fuel rod cladding imitator during its melting,” Nucl. Eng. Des. 363, 110681 (2020). https://doi.org/10.1016/j.nucengdes.2020.110681

E. V. Usov, “Analytical investigation of the fuel rod destruction and melt relocation along the surface of the fuel rod,” J. Phys. Conf. Ser. 1382, 012146 (2019). https://doi.org/10.1088/1742-6596/1382/1/012146

I. A. Kuznetsov and V. M. Poplavskii, Safety of Nuclear Power Plants with Fast-Neutron Reactors (IzdAt, Moscow, 2012) [in Russian].

S. V. Alekseenko, V. E. Nakoryakov, and B. G. Pokusaev, Wave Flow of Liquid Films (Nauka, Novosibirsk, 1992; Begell House, New York, 1994).

L. G. Loitsyanskii, Mechanics of Liquids and Gases (Drofa, Moscow, 2003; Pergamon, Oxford, 1966).

J. C. Asali, T. J. Hanratty, and P. Andreussi, “Interfacial drag and film height for vertical annular flow,” AiChE J. 31, 895–902 (1985). https://doi.org/10.1002/aic.690310604

M. Jackson, “Liquid films in viscous flow,” AiChE J. 1, 231–240 (1955). https://doi.org/10.1002/aic.690010217

T. Karapantsios, S. Paras, and A. Karabelas, “Statistical characteristics of free falling films at high Reynolds number,” Int. J. Multiphase Flow 15, 1–21 (1989). https://doi.org/10.1016/0301-9322(89)90082-7

W. H. Henstock and T. J. Hanratty, “The interfacial drag and the height of the wall layer in annular flows,” AiChE J. 22, 990–1000 (1976). https://doi.org/10.1002/aic.690220607

P. I. Geshev, “A simple model for calculating the thickness of a turbulent liquid film moved by gravity and gas flow,” Thermophys. Aeromech. 21, 553–560 (2014).

P. G. Kosky, “Thin-liquid films under simultaneous shear and gravity forces,” Int. J. Heat Mass Transfer 14, 1220–1224 (1971). https://doi.org/10.1016/0017-9310(71)90216-X

H. Brauer, “Stoffaustausch beim Rieselfilm,” Chem. Ing. Tech. 30, 75–84 (1958). https://doi.org/10.1002/cite.330300205

Funding

The study was carried out with the financial support of the Russian Science Foundation (grant no. 18-79-10013 of August 8, 2018).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Usov, E.V., Lobanov, P.D. & Pribaturin, N.A. Developing Approaches to Analysis of Melt Motion on the Surface of a Fuel Pin. Therm. Eng. 68, 278–284 (2021). https://doi.org/10.1134/S0040601521030083

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040601521030083