Abstract—

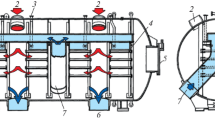

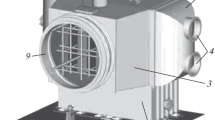

The modern state of the processes connected with design, calculation, and operation of heaters used in steam turbine regeneration systems is reviewed and analyzed on the basis of data available from domestically published and foreign sources. The existing methods for thermal–hydraulic, strength, and vibration design calculations of apparatuses are described; criteria adopted in designing individual areas of heater heat-transfer surfaces are mentioned, and recommendations on taking into account the heat-transfer surface fouling in analyzing its influence on the apparatus’s thermal-efficiency indicators are given. The possibility of using modern computation tools for designing regeneration system apparatuses is considered. A list of materials from which the apparatus heat-transfer surface tubes are made is given; methods for fixing them in shell-and-tube heaters are mentioned, and the level of stresses recommended for individual tube sections is pointed out. The values of key operating parameters—coolant temperatures, pressures and velocities—are given, which are selected based on the results of designing the apparatuses and with reference to foreign standards and other regulatory documents. Recommendations used by foreign manufacturers of heaters as guidelines for selecting vibration-safe length of free spans and tube fastening methods in the bend zone are given. Failures that most frequently occur during operation of high- and low-pressure heaters are pointed out. Some questions concerned with the technology for repairing the regeneration system heaters used as part of a turbine plant are considered. It is shown that there are differences in arranging the repair system and, especially, in the maintenance of heat-transfer apparatuses as concerns the tools necessary for monitoring the equipment condition. The introduction of new technologies for designing and operating heaters in domestic practice will help keep their efficiency and reliability indicators at a high level.

Similar content being viewed by others

Notes

The American Society of Mechanical Engineers (ASME) jointly with the American Society for Testing and Materials (ASTM) publish this code.

REFERENCES

Yu. M. Brodov, K. E. Aronson, A. Yu. Ryabchikov, M. A. Nirenshtein, I. B. Murmanskii, and N. V. Zhelonkin, “The current level and trends in the design and operation of high- and low-pressure heaters for steam turbines of thermal and nuclear power plants in Russia and abroad. Part 1. Types and designs of heaters,” Therm. Eng. 67, 685–698 (2020).

K. E. Aronson, V. I. Brezgin, Yu. M. Brodov, O. V. Komarov, M. A. Nirenshtein, P. N. Plotnikov, A. Yu. Ryabchikov, V. E. Mikhailov, L. A. Khomenok, Yu. G. Sukhorukov, S. N. Gavrilov, A. S. Gimmel’berg, M. A. Gotovskii, P. V. Egorov, V. F. Ermolov, et al., Machine Construction: Encyclopedia, Vol. 4 –10: Heat Exchangers of Technological Subsystems of Turbine Installations, Ed. by Yu. M. Brodov, O. O. Mil’man, V. E. Mikhailov, V. A. Rassokhin, and L. A. Khomenok (Innovatsionnoe Mashinostr., Moscow, 2016) [in Russian].

Yu. M. Brodov, K. E. Aronson, A. Yu. Ryabchikov, and M. A. Nirenshtein, Handbook on Heat Exchangers of Steam Turbine Installations, Ed. by Yu. M. Brodov (Mosk. Energ. Inst., Moscow, 2008) [in Russian].

S. S. Berman, Calculation of Heat Exchangers of Steam Turbine Installations (Gosenergoizdat, Moscow, 1962) [in Russian].

RTM 108.271.23-84. Calculation and Design of High and Low Pressure Surface Heaters (Minist. Energ. Mashinostr., Moscow, 1987).

A. Fraas and M. Otsisik, Calculation and Construction of Heat Exchangers (Atomizdat, Moscow, 1971) [in Russian].

Standards for Closed Feedwater Heaters, 9th ed. (Heat Exchange Institute, Cleveland, OH, 2015), p. 73.

Standards for Shell and Tube Heat Exchangers, 5th ed. (Heat Exchange Institute, Cleveland, OH, 2013), p. 82.

Guide to the Design of Feed Water Heating Plant, BEAMA Publication No. 226 (The British Electrical and Allied Manufacturers’ Association, London, 1968).

V. M. Marushkin, S. S. Ivashchenko, and A. F. Vakulenko, High-Pressure Heaters of Turbine Installations of Thermal and Nuclear Power Plants (Energoatomizdat, Moscow, 1985) [in Russian].

Standards of the Tubular Exchanger Manufacturers Association, 9th ed. (Tubular Exchanger Manufacturers Association, New York, 2007). http://www.tema.org

TR CU 032/2013. Technical Regulation of the Customs Union “On the Safety of Equipment Operating under Excessive Pressure” (2013). http://www.eurasiancommission.org

Common Problems in Feedwater Heaters (Curtiss-Wright, 2017). http://fsrug.org/Presentations2017/20.pdf

RD 24.271.01-88. Methods for Assessing the Vibrational Characteristics of Pipe Systems of Regenerative Low-Pressure Heaters and Network Water Heaters (Mintyazhmash SSSR, Moscow, 1988) [in Russian].

Plymouth Feedwater Heater Tubing. https://www. plymouth.com/products/feedwater-heating-tubing-xls

Feedwater Heater Survey, Report No. GS-7417 (Electric Power Research Institute, New York, 1991).

T. Kuppan, Heat Exchanger Design Handbook (CRC, Boca Raton, FL, 2000).

Yu. M. Brodov, K. E. Aronson, V. I. Brezgin, D. V. Brezgin, S. N. Blinkov, N. V. Zhelonkin, V. K. Kuptsov, I. B. Murmanskii, M. A. Nirenshtein, P. N. Plotnikov, A. Yu. Ryabchikov, and S. I. Khaet, Improving the Efficiency and Reliability of Heat Exchangers of Steam Turbine Installations: Monograph, Ed. by. Yu. M. Brodov, 4th ed. (Ural. Gos. Tekh. Univ. — Ural. Politekh. Inst., Yekaterinburg, 2012) [in Russian].

D. Rizzo, “Rebuilding aging feedwater heaters on-line,” Power Eng. 114 (3) (2010). https://www.power-eng. com/articles/print/volume-114/issue3/departments/what-works/rebuilding-aging-feedwater-heaters-on-line.html

Yu. M. Brodov, K. E. Aronson, Yu. M. Gofman, B. E. Murmanskii, M. A. Nirenshtein, A. Yu. Ryabchikov, and P. N. Plotnikov, Repair and Maintenance of Steam Turbine Unit Equipment: Handbook, Ed. by Yu. M. Brodov, 2nd ed. (Ural. Univ, Yekaterinburg, 2018), Vol. 2 [in Russian].

IRIS Inspection Services®. https://www.iris-inspection.com/

Tube Sleeving. Babcock&Wilcox. https://www.babcock. com/products/tube-sleeving

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by V. Filatov

Rights and permissions

About this article

Cite this article

Brodov, Y.M., Aronson, K.E., Ryabchikov, A.Y. et al. State of the Art and Trends in the Design and Operation of High- and Low-Pressure Heaters for Steam Turbines at Thermal and Nuclear Power Plants in Russia and Abroad: Part 2. Heater Design and Operation Peculiarities. Therm. Eng. 67, 790–799 (2020). https://doi.org/10.1134/S0040601520110038

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040601520110038