Abstract—

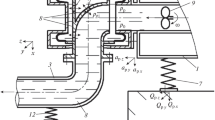

The article presents the results from studying methods and means for reducing the transfer of vibration and pressure pulsations from power installations through elastic vibration isolators of pipelines carrying liquids (cooling water, condensate, or petroleum products) by suppressing the vibration forces and pulsations of the medium by active suppression systems. The results of studies into this subject carried out within the framework of the agreement between the Russian Scientific Foundation and the Tsiolkovskii Kaluga State University are reported. The article discusses the results from calculation and experimental studies aimed at determining the influence of liquid on the vibration-isolating performance of different kinds of pipeline compensators, including those based on bellows, sleeve-type ones made of rubber cord materials, those based on rubber cord shells, and compensators of a new type containing elastic inserts made using thin-layered rubber-metal elements with the minimal interaction between the structure and working medium. The investigations were carried out with the aim to minimize the transfer of vibration through the compensator by improving its design. The results from experimental studies into the effectiveness of joint suppression of the vibration and pressure pulsations by active methods for reducing the transfer of vibration from power installations to the foundation by means of pipeline compensators are presented. It is shown both analytically and experimentally that there is a frequency band in which the vibration forces transferred through the compensator structure are suppressed by the forces from pressure pulsations. The transfer of vibration becomes a factor of ten or more less than it is in the compensator tested without liquid. A physical explanation for this phenomenon is given, and ways of using it in practice are suggested. A two-channel active vibration protection system with a digital control device containing controllers in the form of standard Butterworth, Chebyshev, and band-pass filters, as well as resonance sections in its feedback circuit, is experimentally studied. With the active joint wide-band suppression of vibration forces and pressure pulsations determining the transfer of vibration through the compensators of pipelines with liquid, the effectiveness was found to be up to 32 dB in the frequency band from 10 to 350 Hz.

Similar content being viewed by others

REFERENCES

A. V. Kiryukhin, O. O. Mil’man, and A. V. Ptakhin, “Reducing vibration transfer from power plants by active methods,” Therm. Eng. 64, 912–919 (2017). https://doi.org/10.1134/S0040601517120047

V. I. Popkov and S. V. Popkov, Oscillations of Mechanisms and Structures (Sudarynya, St. Petersburg, 2009) [in Russian].

A. V. Kiryukhin, O. O. Milman, and A. V. Ptakhin, “A search for the physical principles of improving the power unit pipeline expansion joint with fluid vibroisolating properties. Ecology,” Int. J. Appl. Eng. Res. 11, 11176–11183 (2016).

A. V. Kiryukhin, O. O. Milman, A. V. Ptakhin, L. N. Serezhkin, and A. V. Kondratev, “Development and calculation-experimental analysis of pressure pulsations and dynamic forces occurrence models in the expansion joints of pipelines with fluid,” Int. J. Appl. Eng. Res. 12, 8209–8216 (2017).

A. V. Kiryukhin, O. O. Milman, A. V. Ptakhin, G. I. Shaydurova, and A. A. Shaydurov, “Design features of rubber expansion joints and numerical modeling of their stress-strain state in the hydrostatic compression,” Eng. Solid Mech. 5, 177–184 (2017). https://doi.org/10.5267/j.esm.2017.6.001

I. Zh. Bezbakh, V. A. Melik-Shakhnazarov, D. V. Sofiyanchuk, and V. I. Strelov, “New design of active vibration protection devices,” Nauka Obraz.: Nauchn. Izd., No. 9, 22–23 (2012). https://cyberleninka.ru/article/n/ novaya-konstruktsiya-aktivnyh-vibrozaschitnyh-ustroystv

Funding

This work has been carried out based on Agreement no. 16-19-10292 dated May 12, 2016, between the Russian Scientific Foundation and Tsiolkovskii Kaluga State University on providing a grant for carrying out fundamental scientific investigations and search studies under the Investigation of Methods and Means for Reducing the Transfer of Vibration and Pressure Pulsations from Power Installations through Pipeline Vibration Isolators with Liquid by Suppressing Vibration Forces and Pulsations of Medium by Means of Active Damping Systems scientific project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by V. Filatov

Rights and permissions

About this article

Cite this article

Kirjukhin, A.V., Milman, O.O., Ptakhin, A.V. et al. Experimental and Calculation Studies into the Possibilities of Improving the Vibration Isolation of Power Installation Pipelines. Therm. Eng. 67, 430–440 (2020). https://doi.org/10.1134/S0040601520070046

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040601520070046