Abstract—

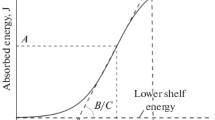

The drum metal properties of the BKZ-160-100FB and TP-85 boilers installed at the Irkutsk TETs-11 combined heat and power plant were investigated after these boilers had been in operation for 259 000 and 224 000 h, respectively, and after they had been subjected to low-temperature restorative heat treatment, which was carried out with steam produced by an external boiler after replacing all unions installed in the drum’s water volumes. “Plugs” made of grade 22K carbon steel and of grade 16GNM low-alloy steel cut from the drum shell rings were used as research subjects. The samples were subjected to metallographic analysis, tensile tests, impact bending test, and hardness measurement test. The results of tensile tests carried out at room temperature and at the metal operation temperature are presented. The results of drum metal U-notched specimens impact strength tests obtained at room temperature are given. Impact strength tests on V-notched specimens were carried out for samples after their metal had been subjected to low-temperature restorative heat treatment in the temperature range from –10 to +80°C. Based on the results of the V-notched specimens tests, the ductile constituent in the fractures was determined, and the drum metal ductile-to-brittle transition temperature was determined. The microstructure and mechanical properties that the drum metal had after having been in operation and having passed subsequent low-temperature restorative heat treatment were in compliance with the requirements of the relevant regulatory documents. After the boiler drum metal had been subjected to low-temperature restorative heat treatment, the studied steel samples showed a higher proof strength both at room temperature and at the operation temperature. Based on the data obtained from the investigations of boiler drum metal after it had been in operation and then subjected to low-temperature restorative heat treatment, technical diagnostics, and numerical strength analysis, it was recommended to extend the service life of the drums at their design (certificate) parameters.

Similar content being viewed by others

REFERENCES

E. A. Grin’, A. E. Anokhov, A. V. Zelenskii, and I. V. Fedina, “Studying the metal of steam boiler drums made of grade 16GNM steel after its long-term operation,” Therm. Eng. 57, 495–501 (2010).

N. V. Ababkov, A. N. Smirnov, A. I. Kopytov, and A. A. Trubin, “Evaluation of the condition of melted metal of a high-pressure boiler drum by the coercive force of the metal,” Vestn. Kuzbas. Gos. Tekhn. Univ., No. 2, 57–60 (2011).

M. S. Saikova, The Influence of Technological Defects on the Strength and Resource of the Metal of the Cases of Thermomechanical Equipment of Thermal Power Plants Under Thermomechanical Effects, Candidate’s Dissertation in Engineering (St. Petersburg, 2011).

P. A. Antikain, Metals and Strength Calculation of Boilers and Pipelines, 3rd ed. (Energoatomizdat, Moscow, 1990) [in Russian].

V. M. Goritskii, Applying the Characteristics of Impact Elasticity in Engineering Practice (Metallurgizdat, Moscow, 2016) [in Russian].

E. A. Grin’, “Evaluating the possibility of brittle fractures in the drums of high-pressure boilers,” Therm. Eng. 52, 603–607 (2005).

Yu. V. Balashov, L. V. Nadtsyna, E. I. Kaminskaya, and L. V. Davlyatova, “Studying the metal of a drum, destroyed during hydroshaping,” Elektr. Stn., No. 12, 15–17 (1993).

L. S. Ozhigov, A. S. Mitrofanov, G. D. Tolstolutskaya, R. L. Vasilenko, A. G. Rudenko, V. V. Ruzhitskii, N. D. Rybal’chenko, and S. V. Shramchenko, “Comprehensive investigation of the metal in drums of boilers at thermal power stations,” Therm. Eng. 64, 350–356 (2017). https://doi.org/10.1134/S0040601517050068

E. A. Grin’, “Brittle fractures of the drums of high-pressure boilers: Main causes and methods for preventing them,” Therm. Eng. 55, 137–143 (2008).

G. A. Tulyakov, I. S. Kovalev, S. F. Bakhteev, and M. A. Aksel’rod, “Low-temperature recovery heat treatment of steam boiler drum elements,” Teploenergetika, No. 7, 11–14 (1988).

G. A. Gulyakov, I. S. Kovalev, O. N. Zharikova, E. A. Averchenkov, S. F. Bakhteev, M. A. Aksel’rod, and I. N. Yushkova, “Experience in conducting low-temperature recovery heat treatment of metal of drums from carbon and low alloy steels,” Elektr. Stn., No. 3, 36–38 (1990).

S. F. Bakhteev, O. N. Zharikova, V. N. Skorobogatykh, and G. A. Tulyakov, “A method of recovery of power equipment elements from carbon and low alloy steel,” Patent RF No. 2049148, Byull. Izobret., No. 33 (1995).

SO 153-34.26.608-2003. Instructions for Inspection and Repair Technology for High-Pressure Boiler Drums (TsPTI ORGRES, Moscow, 2004).

SO 153-34.17.442-2003. Instructions for Extending the Life of High Pressure Boiler Drums (Minenergo RF, Moscow, 2004).

RD 10-249-98. Strength Calculation Standards for Stationary Boilers and Steam and Hot Water Pipelines (ZAO NTTs PB, Moscow, 2010).

GOST 5520-79. Rolled Carbon, Low-Alloy and Alloy Steel Sheets and Plates for Boilers and Pressure Vessels. Specifications (Izd. Standartov, Moscow, 1980).

Heat-Resistant Steel 16GNM. The Central Metal Website of the Russian Federation. http://metallicheckij-portal.ru

RD 10-577-03. Typical Instructions for Metal Control and Extension of the Life of the Main Elements of Boilers, Turbines and Pipelines of Thermal Power Plants (Gosgortekhnadzor Rossii, Moscow, 2003).

GOST 1497-84. Metals. Methods of Tension Tests (Izd. Standartov, Moscow, 1986).

GOST 9651-84. Metals. Methods of Tension Tests at Elevated Temperatures (Gosstandart SSSR, Moscow, 1986).

GOST 9454-78. Metals. Method for Testing the Impact Strength at Low, Room and High Temperature (Gosstandart SSSR, Moscow, 1979).

GOST 4543-2016. Structural Alloy Steel Products. Specifications (Standartinform, Moscow, 2017).

GOST 9012-59. Metals. Method of Brinell Hardness Measurement (Standartinform, Moscow, 2007).

STO 17230282.27.100.005. Main Elements of Boilers, Turbines and Pipelines of Thermal Power Plants. Metal Condition Control. Standards and Requirements (RAO EES Rossii, Moscow, 2008).

GOST 5640-68. Steel. Metallographic Method for Determination of Microstructure of Sheets and Bands (Izd. Standartov, Moscow, 1988).

GOST 1778-70. Steel. Metallographic Methods for the Determination of Nonmetallic Inclusions (Gosstandart SSSR, Moscow, 1972).

P. D. Odesskii and I. I. Vedyakov, Impact Strength of Steels for Metal Structures (Intermet Inzhiniring, Moscow, 2003).

ACKNOWLEDGMENTS

We are grateful to A.V. Nikolaenko, Head of the Nondestructive Testing and Diagnostics Laboratory at the Ural Power Industry Engineering Center, a branch of OAO UralVTI, for the aid rendered in carrying out the mechanical tests.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by V. Filatov

Rights and permissions

About this article

Cite this article

Lepikhin, S.V., Gladkovskii, S.V. & Granovskii, O.G. The Influence of Low-Temperature Restorative Heat Treatment on the Structure and Mechanical Properties of Boiler Drum Metal after Long-Term Operation. Therm. Eng. 67, 138–144 (2020). https://doi.org/10.1134/S0040601520020020

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040601520020020