Abstract

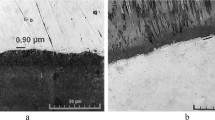

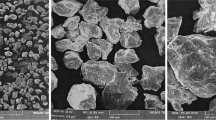

Schemes are presented for experimental setups (reactors) developed at leading scientific centers connected with the development of technologies for the deposition of coatings using the CVD method: at the Technical University of Braunschweig (Germany), the French Aerospace Research Center, the Materials Research Institute (Tohoku University, Japan) and the National Laboratory Oak Ridge (USA). Conditions and modes for obtaining the coatings with high operational parameters are considered. It is established that the formed thermal barrier coatings do not fundamentally differ in their properties (columnar microstructure, thermocyclic resistance, thermal conductivity coefficient) from standard electron-beam condensates, but the highest growth rates and the perfection of the crystal structure are achieved in the case of plasma-chemical processes and in reactors with additional laser or induction heating of a workpiece. It is shown that CVD reactors can serve as a basis for the development of rational and more advanced technologies for coating gas turbine blades that are not inferior to standard electron-beam plants in terms of the quality of produced coatings and have a much simpler and cheaper structure. The possibility of developing a new technology based on CVD processes for the formation of thermal barrier coatings with high operational parameters is discussed, including a set of requirements for industrial reactors, high-performance sources of vapor precursors, and promising new materials.

Similar content being viewed by others

References

G. P. Nagoga, Effecive Cooling Methods of Blades of High-Temperature Gas Turbines: Study Guide (Mosk. Aviats. Inst., Moscow, 1996) [in Russian].

S. V. Khar’kovskii, V. P. Pochuev, V. S. Kinzburskii, and A. A. Mukhin, Comparison of Most Widespread Cooling Schemes of Working Blades of High-Temperature High-Pressure Turbines, Ed. by M. Ya. Ivanov (Torus, Moscow, 2010), pp. 171–190 [in Russian].

A. S. Tikhonov, S. I. Sendyurev, and V. T. Khairulin, “Designing a facility for thermocyclic testing of complex multilayer thermal coatings of gas turbine blades,” Vestn. PNIPU. Aerokosm. Tekh., No. 38, 61–71 (2014). http://vestnik.pstu.ru/aero/archives/?id= &folder_id=4062.

R. P. Pridorozhnyi, A. V. Sheremet’ev, and A. P. Zin’kovskii, “Effectiveness evaluation of application of thermal coatings on cooled working blades of high pressure turbines of aviation gas turbine engines,” Vestn. Dvigatelestr., No. 1, 52–56 (2014).

E. N. Kablov and S. A. Muboyadzhyan, “Thermal coatings for high pressure turbine blades for prospective gas-turbine engines,” Metally, No. 1, 5–13 (2012).

A. A. Inozemtsev, M. A. Nikhamkin, and V. L. Sandratskii, Fundamentals of Construction of Aviation Engines and Power Units (Mashinostroenie, Moscow, 2007), in Ser.: Gas-Turbine Engines: Textbook for Higher Education Institutions [in Russian].

B. A. Movchan and K. Yu. Yakovchuk, “High-temperature protective coatings produced by EB-PVD,” J. Coating Sci. Technol. 1, 96–110 (2014).

K. Yu. Yakovchuk, “Thermal conductivity and thermocyclic longevity of condensation thermal barrier coatings,” Sovrem. Elektrometall., No. 4, 25–31 (2014).

K. von Niessen and M. Gindrat, “Plasma spray-PVD: A new thermal spray process to deposit out of the vapor phase,” J. Therm. Spray Technol. 20, 736–743 (2011).

Thermal Barrier Coatings, Ed. by H. Xu and H. Guo (Woodhead, Oxford, PA, 2011).

D. A. Chubarov and P. V. Matveev, “New ceramic materials for thermal protection coatings of gas turbine engines working blades,” Aviats. Mater. Tekhnol., No. 4, 43–46 (2013).

P. T. Kolomytsev, High-Temperature Protection Coatings for Nickel Alloys (Metallurgiya, Moscow, 1991) [in Russian].

B. Préauchat, Doctoral Thesis in Materials Science and Engineering (Inst. National Polytechnique de Lorraine, 2001). http://docnum.univ-lorraine.fr/public/INPL_T_2001_PREAUCHAT_B.pdf.

D. Zhu and R. A. Miller, “Development of advanced low conductivity thermal barrier coatings,” Int. J. Appl. Ceramic Technol. 1, 86–94 (2004).

A. A. Smirnov and S. A. Budinovskii, “Increasing the heat resistance of condensation-diffusion coatings for turbine blades from alloy ZhS32,” Aviats. Mater. Tekhnol., No. 2, 3–10 (2016).

P. L. Fauchais, J. V. R. Heberlein, and M. I. Boulos, Thermal Spray Fundamentals: From Powder to Part (Springer-Verlag, New York, 2014). doi 10.1007/978-0-387-68991-3

S. A. Muboyadzhyan, S. A. Budinovskii, A. M. Gayamov, and A. A. Smirnov, “Obtaining ceramic heat protection coatings for working blades of aviation gas turbine engines by the magnetron method,” Aviats. Mater. Tekhnol., No. 4, 3–8 (2012).

D. A. Chubarov, S. A. Budinovskii, and A. A. Smirnov, “Magnetron method for application of ceramic layers of thermal coatings,” Aviats. Mater. Tekhnol., No. 4, 23–30 (2016).

M. L. Hitchman, Chemical Vapor Deposition: Principles and Applications, Ed. by K. F. Jensen (Academic, London, 1993).

V. G. Syrkin, CVD method. Chemical Vapor-Phase Deposition (Nauka, Moscow, 2000) [in Russian].

Yu. A. Tamarin, Heat-Resistant Diffusion Coatings of Gas Turbine Engine Blades, Ed. by A. T. Tumanov (Mashinostroenie, Moscow, 1978) [in Russian].

B. A. Pint, I. G. Wright, W. Y. Lee, Y. Zhang, K. Prüβner, and K. B. Alexander, “Substrate and bond coat compositions: Factors affecting alumina scale adhesion,” Mater. Sci. Eng. 245, 201–211 (1998).

T. M. Brammer, Master Thesis in Materials Science and Engineering (Iova State Univ., Ames, Iowa, 2011), Available from UNT Digital Library.

V. M. Peshkova and N. V. Mel’chakova, β-Diketones (Nauka, Moscow, 1986) [in Russian].

M. Pulver, Chemische Gasphasenabscheidung von Zirkoniumdioxid, Yttriumoxid und Aluminiumoxid aus β-Diketonaten und Alkoholaten: Dissertation (Braunschweig Technical Univ., Braunschweig, 2000).

G. Wahl, W. Nemetz, M. Giannozzi, S. Rushworth, D. Baxter, N. Archer, F. Cernuschi, and N. Boyle, “Chemical Vapor deposition of TBC: an alternative process for gas turbine components,” J. Eng. Gas Turbines Power 123, 520–524 (2000).

W. Nemetz, Chemical Vapour Deposition of Thermal Barrier Coatings on Turbine Blades: Dissertation (Braunschweig Technical Univ., Braunschweig, 2004).

G. Wahl, Ch. Metz, and S. Samoilenkov, “Thermal barrier coatings,” J. De Phys. IV France 11, Pr3-835–Pr3-846 (2001). doi 10.1051/jp4:20013105

B. Préauchat and S. Drawin, “Isothermal and cycling properties of zirconia-based thermal barrier coatings deposited by PECVD,” Surf. Coat. Technol. 146–147, 94–101 (2001). doi 10.1016/S0257-8972(01)01454-2

B. Préauchat and S. Drawin, “Properties of PECVDdeposited thermal barrier coatings,” Surf. Coat. Technol. 142–144, 835–842 (2001). doi 10.1016/S0257-8972(01)01211-7

S. Chevillard, Étude d'un Procédé de Dépôt Chimique en Phase Vapeur Assisté par un Plasma Micro-Ondes pour la Réalization de Revêtements de Zircone Yttriée. Thèse de l'Université Paris XI Orsay (1997). https://tel.archivesouvertes.fr/tel-00976254/document

T. Kimura and T. Goto, “Rapid synthesis of yttria-stabilized zirconia films by laser chemical vapor deposition,” Mater. Trans. 44, 421–424 (2003).

R. Tu and T. Goto, “Thermal cycle resistance of yttria stabilized zirconia coatings prepared by MO-CVD,” Mater. Trans. 46, 1318–1323 (2005).

T. Goto, “A review: Structural oxide coatings by laser chemical vapor deposition,” J. Wuhan Univ. Technol. 31, 1–5 (2016). doi 10.1007/s11595-016-1319-6

T. Goto, “Integration of multifunctional properties in thermal barrier coatings by chemical vapor deposition,” in Ceramic Integration and Joining Technologies: From Macro to Nanoscale, ed. by M. Singh, T. Ohji, R. Asthana, and S. Mathur (Wiley, Hoboken, NJ, 2011), pp. 393–413. doi 10.1002/9781118056776.ch13

V. E. Haven, “Chemical vapor deposition of turbine thermal barrier coatings,” NASA Glenn Research Center Technical Report No. FR-60383 (NASA, Cleveland, OH, 1999). https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20000010544.pdf.

V. G. Varanasi, T. M. Besmann, E. A. Payzant, B. A. Pint, J. L. Lothian, and T. J. Anderson, “Highgrowth rate YSZ thermal barrier coatings deposited by MOCVD demonstrate high thermal cycling lifetime,” Mater. Sci. Eng.: A 528, 978–985 (2001).

V. G. Varanasi, T. M. Besmann, R. L. Hyde, E. A. Payzant, T. J. Anderson, “MOCVD of YSZ coatings using β-diketonate precursors,” J. Alloys Compd. 470, 354–359 (2009).

B. A. Movchan and K. Yu. Yakovchuk, “Advanced graded protective coatings, deposited by EB-PVD,” Mater. Sci. Forum 546, 1681–1688 (2007). doi 10.4028/www.scientific.net/MSF.546-549.1681

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © I.K. Igumenov, A.N. Aksenov, 2017, published in Teploenergetika.

Rights and permissions

About this article

Cite this article

Igumenov, I.K., Aksenov, A.N. Thermal barrier coatings on gas turbine blades: Chemical vapor deposition (Review). Therm. Eng. 64, 865–873 (2017). https://doi.org/10.1134/S0040601517120035

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040601517120035