Abstract

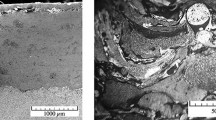

Results of investigations of the influence of a Cr–CrC ion-plasma sprayed protective coating on characteristics and the intensity of erosion wear of grade 15Kh11MF steel at a gas–abrasive flow incidence angle of 30° and an experimental specimen (target) surface temperature of 550°С are presented. The Cr–CrC ion-plasma sprayed coating was formed in a Gefest vacuum installation by magnetron deposition. Investigations of the formed coating were carried out using a research and experimental facility complex that provided the study of the composition and structure of the coating, measurement of its thickness, roughness, microhardness, and determination of its relative resistance at the combined action of the gas–abrasive flow and high temperatures. The Cr–CrC coating with a thickness of 6.5 ± 0.3 μm has a finegrained structure with grains with dimensions of 20–40 nm and contains layers of chromium and chromium carbide. The main coating element is chromium. Its content in carbide layers is 89.4–91.9% at a carbon content of 6.8–9.5%. The coating microhardness is H 0.05 = 1350 ± 50 HV. The maximum wear of the 15Kh11MF steel target is observed at the angle of the gas–abrasive flow incidence that is close to 30° (30 7°). With this incidence angle and a target surface temperature of 550°С, the Cr–CrC coating extends the term to the surface failure and the appearance of a clear abrasive trace no less than four times. The coating failure has a local character, i.e., the target surface forms islands with the coating, between which the intensive wear of the base material occurs.

Similar content being viewed by others

References

A. V. Shcheglyaev, Vapor Turbines. A Handbook for High Education Institutes (Energoatomizdat, Moscow, 1993). In 2 books. Book 1. 6th ed. [in Russian].

V. A. Khaimov, Yu. Ya. Kachuriner, and Yu. A. Voropaev, “Erosion wear caused by coerse particles in the flow–through part of the medium–pressure stage of T–250/300–240 turbines,” Power Technol. Eng. 38 (5), 279–284 (2004).

V. G. Orlik, N. V. Averkina, A. A. Aznabaev, Yu. Ya. Kachuriner, I. A. Nosovitskii, M. A. Filaretov, and V. F. Chervonnyi, “Reducing abrasive erosion of superheated–steam turbine stages,” Elektrich. Stantsii, No. 12, 33–41 (2008).

L. I. Seleznev, A. F. Mednikov, and A. B. Tkhabisimov, “Analysis of the erodent statistical characteristics behavior under solid particle erosion,” Vestnik MEI, No. 5, 25–29 (2015).

L. I. Seleznev, A. F. Mednikov, and A. B. Tkhabisimov, “Gas–abrasive flow attack angle influence on the erosive wear of flat X20Cr13 steel target,” Neft. Khoz., No. 7, 116–119 (2015).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © L.I. Seleznev, A.F. Mednikov, A.B. Tkhabisimov, A.V. Ryzhenkov, G.V. Kachalin, O.S. Zilova, 2016, published in Teploenergetika.

Rights and permissions

About this article

Cite this article

Seleznev, L.I., Mednikov, A.F., Tkhabisimov, A.B. et al. Determination of characteristics of erosion wear of grade 15Kh11MF steel with the Cr–CrC ion-plasma sprayed coating. Therm. Eng. 63, 449–453 (2016). https://doi.org/10.1134/S0040601516060069

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040601516060069